Rotation preventing member and scroll compressor

A scroll compressor, anti-rotation technology, used in rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve problems such as abnormal wear and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

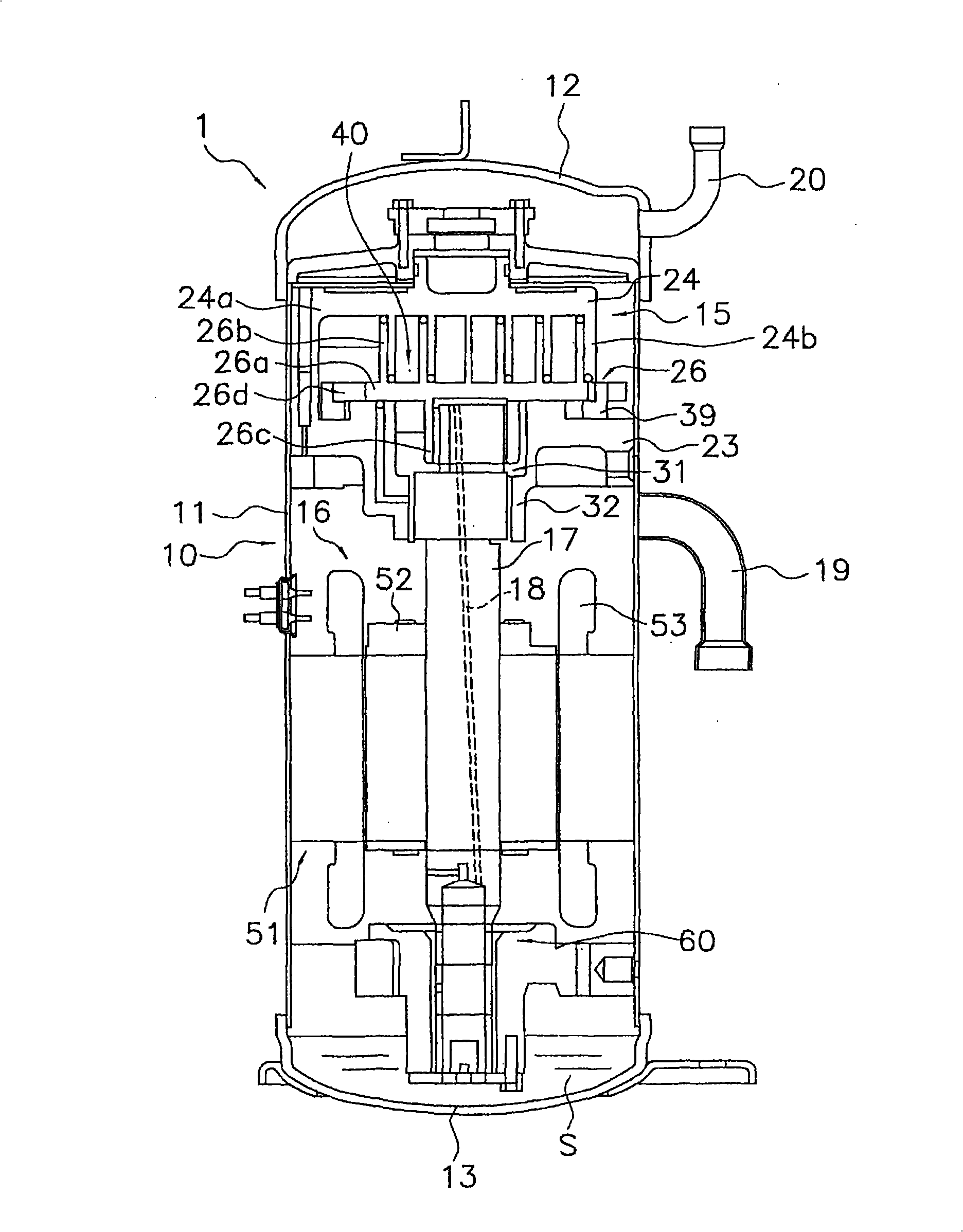

[0096] The low-pressure dome-type scroll compressor 1 of the first embodiment of the present invention constitutes a refrigerant circuit together with an evaporator, a condenser, an expansion mechanism, etc., and plays a role of compressing the gas refrigerant in the refrigerant circuit, as shown in figure 1 As shown, this low-pressure dome-type scroll compressor 1 is mainly composed of a vertically long cylindrical sealed dome-shaped casing 10, a scroll-type compression pump unit 15, a drive motor 16, a lower main bearing 60, a suction pipe 19 and The discharge pipe 20 constitutes. In addition, the low-pressure dome-type scroll compressor 1 is a vertical compressor, and the scroll compressor pump unit 15 is provided above the drive motor 16 . The components of the low pressure dome scroll compressor 1 will be described in detail below.

[0097] [Details of Components of Low Pressure Dome Scroll Compressor]

[0098] (1) Housing

[0099] The casing 10 is mainly composed of t...

no. 2 Embodiment approach

[0150]The low-pressure dome-type scroll compressor 1 according to the second embodiment of the present invention is the same as the low-pressure dome-type scroll compressor 1 according to the first embodiment except for the Oldham ring and the operation at startup. Therefore, only the operation of the Oldham ring 339 and startup will be described here.

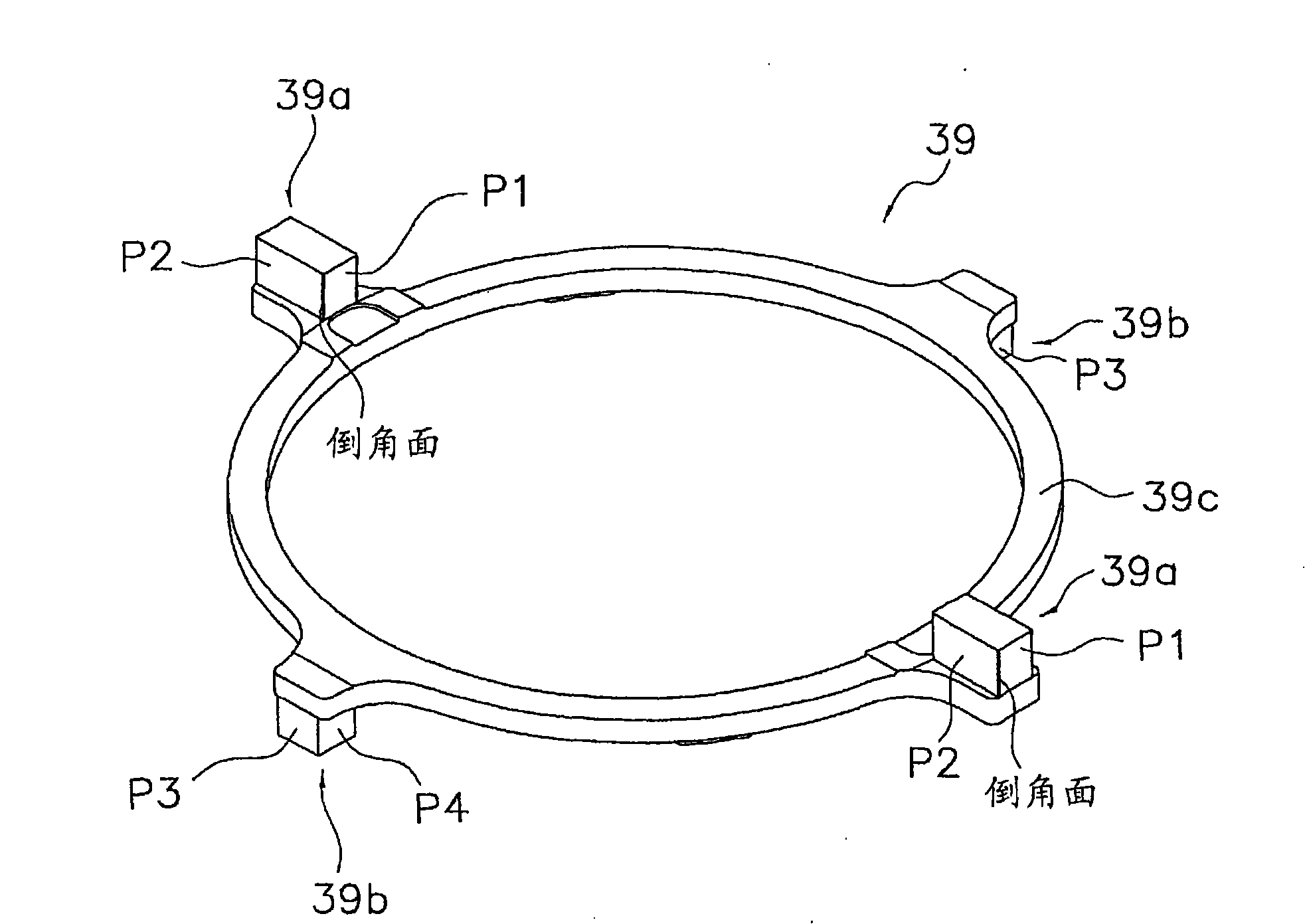

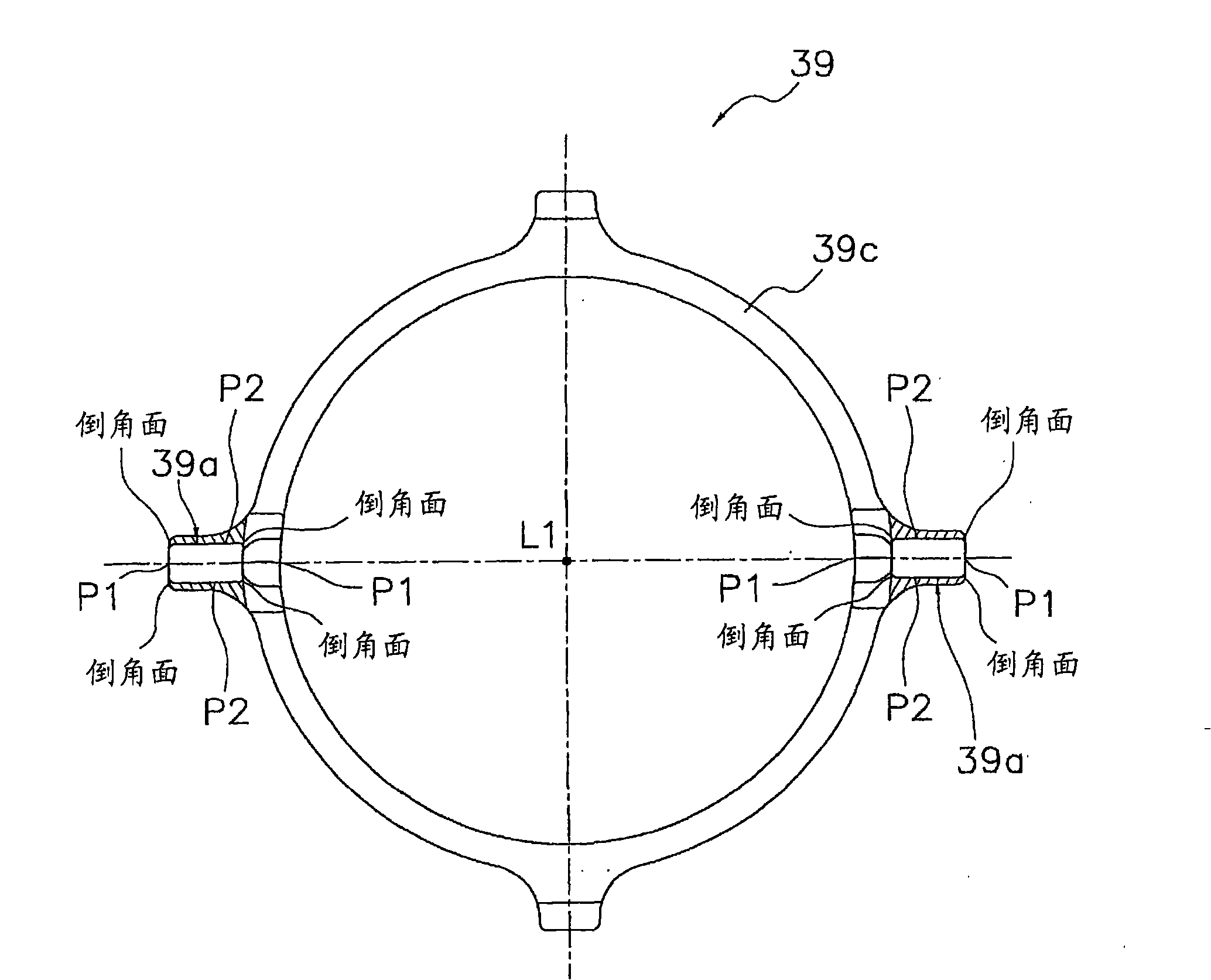

[0151] Such as Figures 14 to 18 As shown, the Oldham ring 339 of the second embodiment is mainly composed of a main body 39c, a movable scroll side key portion 339a, and a housing side key portion 39b. In addition, in this description, the part which attached|subjected the same code|symbol as the part concerning 1st Embodiment shows the part similar to the part concerning 1st Embodiment. Such as Figure 15 with Figure 16 As shown, the main body 39c is a generally annular shaped body. The movable scroll side key portion 339a is a pair of protrusions that face across the axis L1 of the main body 39c and extend on one side ...

no. 3 Embodiment approach

[0167] Except for the movable scroll, the low-pressure dome-type scroll compressor 101 according to the third embodiment of the present invention is the same as the low-pressure dome-type scroll compressor 1 according to the first embodiment. Therefore, only the movable scroll 126 will be described here. In addition, in this embodiment, as the Oldhams ring, a conventional Oldhams ring may be used, the Oldhams ring 39 of the first embodiment may be used, or the Oldhams rings 139 and 239 of modified examples of the first embodiment may be used. The Oldham ring 339 of the second embodiment may also be used.

[0168] Such as Figure 19 with 20 As shown, the movable scroll 126 of the third embodiment is mainly composed of the following parts: an end plate 126a; a scroll-shaped (involute-shaped) overlapping portion 26b formed on the upper surface side of the end plate 126a; and The bearing portion 26c is formed on the lower surface side of the end plate 126a. In addition, in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com