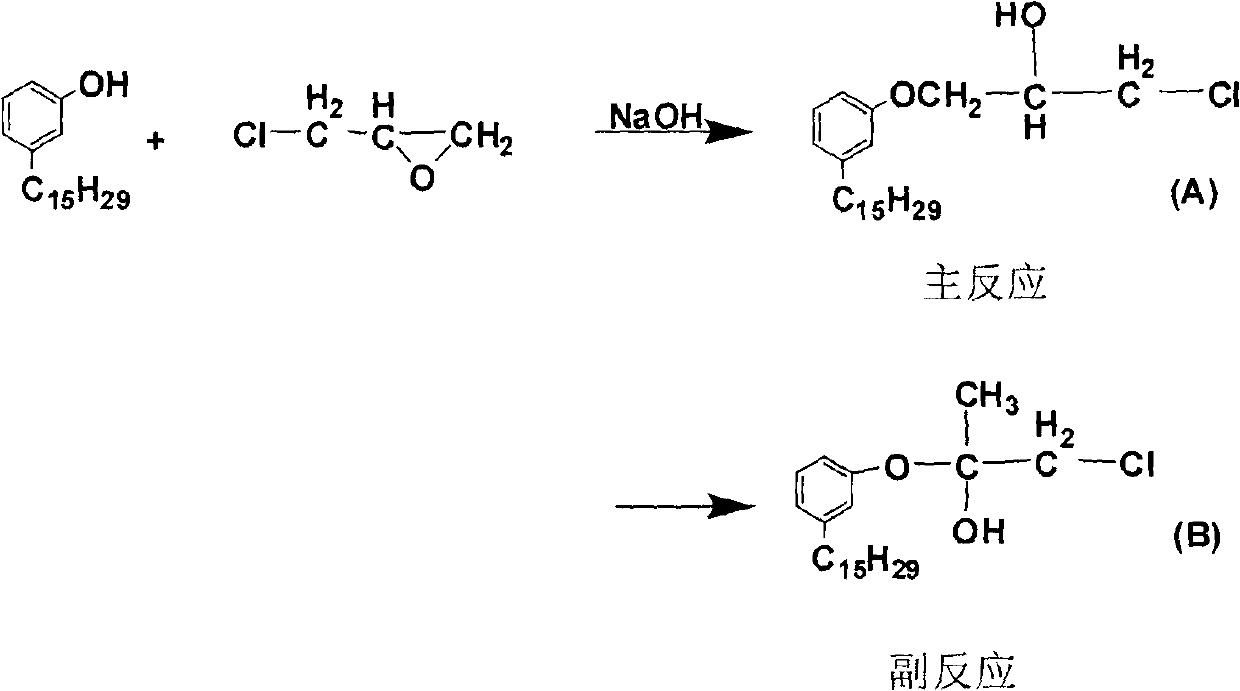

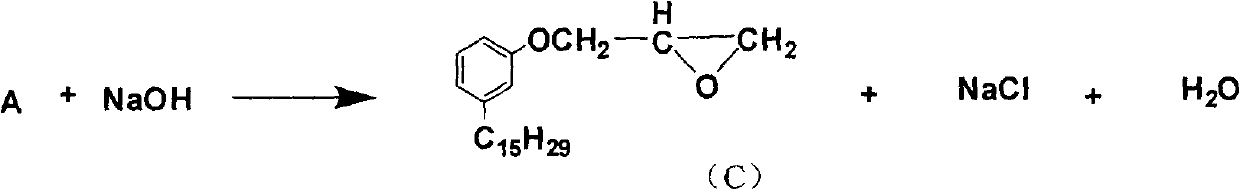

Preparation method of anacardol glycidol ether

A technology of glycidyl ether and cardanol, applied in the chemical field, can solve the problems of large amount of epichlorohydrin, deep reaction color, complicated operation, etc., and achieve the effect of reducing color, accelerating layering, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 210 grams of cardanol, 77 grams of epichlorohydrin, 82.6 grams of sodium hydroxide solution of a certain concentration, on a 1L four-necked reaction flask, agitator, thermometer, condenser, gas outlet, gas outlet (feeding port) are equipped with ), put in 210 grams of cardanol and stir with nitrogen for 2 minutes to get rid of the air, add 77 grams of epichlorohydrin, continue to stir and let out the air, control the temperature and add 82.6 grams of sodium hydroxide solution at 40 to 50 degrees Celsius, and the dropping time is fast and then slow. After the dropwise addition, the temperature was raised to 75 degrees centigrade, and the temperature was kept for 8 hours. After static settling, the material is discharged and centrifuged to obtain the first batch of products with light color, clear and transparent product, and the filter residue is dried to obtain a large amount of high-purity sodium chloride, which can be used in industry.

[0018] Product quality standa...

Embodiment 2

[0020] 210 grams of cardanol, 70 grams of epichlorohydrin, 77 grams of sodium hydroxide solution of a certain concentration, on a 1L four-necked reaction flask, agitator, thermometer, condenser, gas outlet, gas outlet (feeding port) are equipped with ), put in 210 grams of cardanol and stir with nitrogen for 2 minutes to get rid of the air, add 70 grams of epichlorohydrin, continue to stir and let out the air, control the temperature at 40 to 50 degrees Celsius and add 77 grams of sodium hydroxide solution, and the dropping time is fast and then slow. After the dropwise addition, the temperature was raised to 75 degrees centigrade, and the temperature was kept for 7.5 hours. After static settling, the material is discharged and centrifuged to obtain the first batch of products with light color, clear and transparent product, and the filter residue is dried to obtain a large amount of high-purity sodium chloride, which can be used in industry.

[0021] Product quality standard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com