New process for comprehensively utilizing potassium feldspar

A technology of potassium feldspar and process, which is applied in the field of new technology for comprehensive utilization of potassium feldspar, can solve the problems of low utilization rate of potassium feldspar aluminum and silicon resources, low quality of potassium carbonate, environmental pollution, etc., and achieve maximum, Realize the value of silicon resources and the effect of realizing the value of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

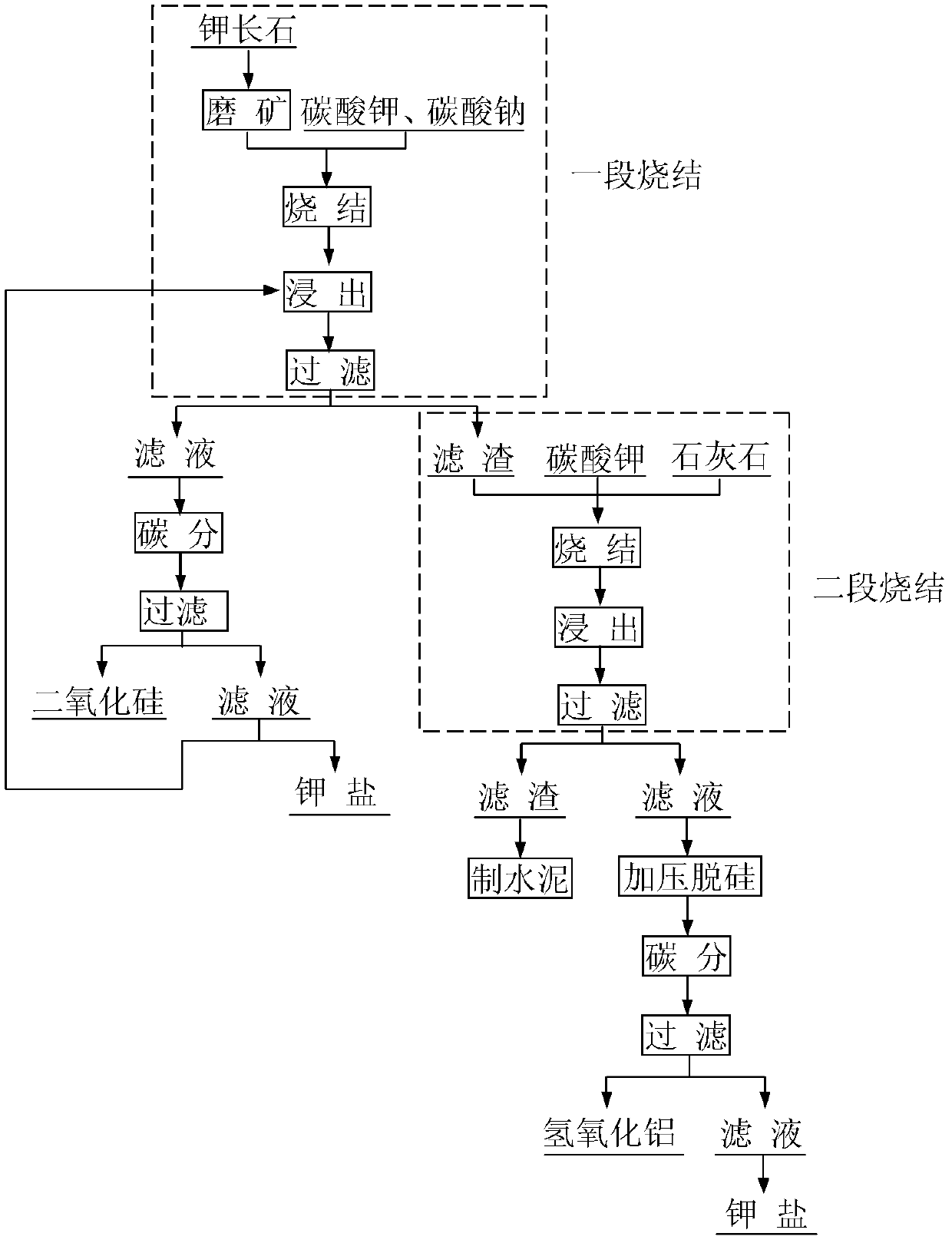

Method used

Image

Examples

Embodiment 1

[0028] Potassium feldspar is ground to -320 mesh, mixed with powdery or granular potassium carbonate, and its dosage is based on the alkali ratio (K 2 o 总 +Na 2 o 总 ) / (Al 2 o 3总 +Fe 2 o 3总 ) is calculated as 1.25, after the two are mixed and granulated, they are sintered at 850°C for 20 minutes, and the obtained clinker is ground to -80 mesh, in KOH: 60g / L, K 2 CO 3 : Filter after leaching in the mixed solution of 60g / L, the leaching temperature is 60°C, the time is 20min, the leaching rates of potassium, aluminum and silicon in potassium feldspar potassium calculated by the mass composition of filter residue are: 81.5%, 14.3, 41.2% respectively .

[0029] The filtrate is carbonized at 60°C until the pH value is 7-8, and the precipitation rate of silicon in the filtrate can reach more than 98%.

[0030] Wash and grind the filter residue to -200 mesh, add powdered or granular potassium carbonate and -320 mesh limestone, and the dosage is based on the alkali ratio (K 2...

Embodiment 2

[0034] Potassium feldspar is ground to -320 mesh, mixed with powdery or granular potassium carbonate, and its dosage is based on the alkali ratio (K 2 o 总 +Na 2 o 总 ) / (Al 2 o 3总 +Fe 2 o 3总 ) is calculated as 1.25, after mixing and granulating the two, sintering at 850°C for 20 minutes, the obtained clinker is ground to -120 mesh, and in KOH: 80g / L, K 2 CO 3 : Filter after leaching in 80g / L mixed solution. The leaching temperature is 60°C and the time is 20min. Calculate the leaching rates of potassium, aluminum and silicon in potassium feldspar potassium based on filter residue components: 83.8%, 13.1%, 41.7% .

[0035] The filtrate is carbonized at 80°C until the pH value is 7-8, and the precipitation rate of silicon in the filtrate can reach 95%.

[0036] Wash and grind the filter residue to -200 mesh, add powdered or granular potassium carbonate and -260 mesh limestone, and the dosage is based on the alkali ratio (K 2 o 总 +Na 2 o 总 ) / (Al 2 o 3总 +Fe 2 o 3总 ) i...

Embodiment 3

[0040] Potassium feldspar is ground to -200 mesh, mixed with powdery or granular potassium carbonate, and its dosage is based on the alkali ratio (K 2 o 总 +Na 2 o 总 ) / (Al 2 o 3总 +Fe 2 o 3总 ) is calculated as 1.05, after the two are mixed and granulated, they are sintered at 810°C for 40 minutes, and the obtained clinker is ground to -160 mesh, and in KOH: 50g / L, K 2 CO 3 : Filter after leaching in 50g / L mixed solution. The leaching temperature is 60°C and the time is 20min. The leaching rates of potassium, aluminum, and silicon in potassium feldspar potassium calculated by filter residue components are: 79.6%, 11.9%, and 39.8% respectively. .

[0041] The filtrate is carbonized at 60°C until the pH value is 8, and the precipitation rate of silicon in the filtrate can reach more than 98%.

[0042] Wash and grind the filter residue to -320 mesh, add powdered or granular potassium carbonate and -200 mesh limestone, and the dosage is based on the alkali ratio (K 2 o 总 +...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com