Method for welding copper oxygen lance end for steelmaking with steel pipe sub

A welding method and a technology of copper ends, which are applied in the field of workpiece welding, can solve the problems of low weld strength, large residual stress, and large difference in thermal conductivity, etc., and achieve the effects of ensuring welding quality, eliminating residual stress, and improving weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

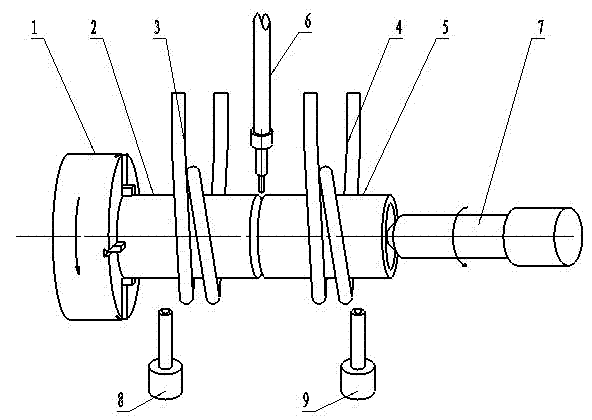

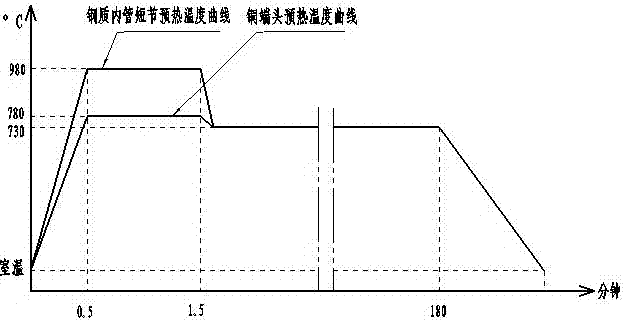

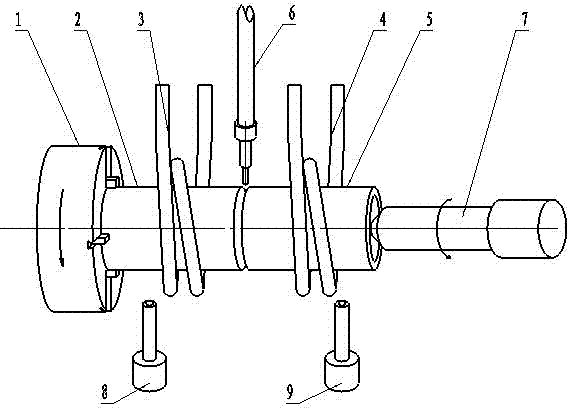

[0015] The copper end of the oxygen lance used in steelmaking is made of pure copper, and the steel pipe nipple (including the inner pipe and outer pipe) is made of No. 20 steel. The melting point temperature difference between the two materials is about 400°C, and the mechanical properties are also very different. The purpose of preheating before welding is to improve the molecular activity, so that the alloy phase region of the transition layer can be formed as wide as possible after welding, so as to improve the mechanical properties of the weld. From the perspective of production cost and operability, it is impossible to obtain different preheating temperatures for two workpieces by preheating in an ordinary electric furnace, while using the same preheating temperature cannot take into account the optimum conditions for both copper and steel materials. Optimum preheating temperature zone. In addition, according to the ordinary heating process, the heating time of the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com