Device for treatment of waste drying gas from sizing in textile dyeing and finishing and process for the same

A technology for treating device and waste gas, which is applied in solid separation, external electrostatic separator, chemical instruments and methods, etc., can solve the problems of inconvenient cleaning, poor safety, and easy blocking of equipment, achieve safe and reliable use, reduce operating costs, increase Effect of gas humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

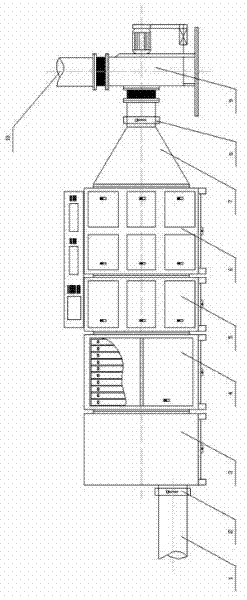

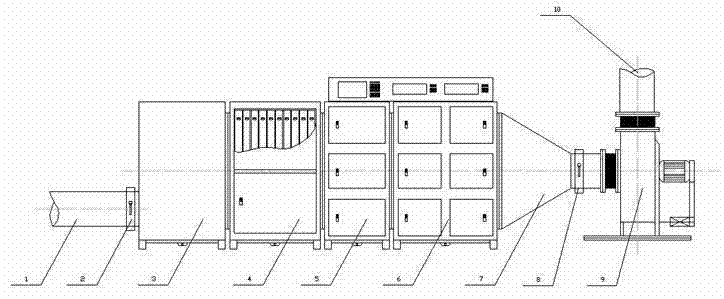

[0018] like figure 1 As shown, the condensing electrostatic treatment device for dyeing and finishing drying exhaust gas includes a collection pipe 1 connected in sequence, a front fire damper 2, a centrifugal wheel 3, a condenser 4, a honeycomb electric field 5, a plate-line double-zone electric field 6, and a guide Flow pipe 7, rear fire damper 8, induced draft fan 9 and exhaust pipe 10, centrifugal wheel 3 are installed on the motor.

[0019] The centrifugal wheel 3 is a rhombic oblate cone made of double metal mesh. The condenser 4 is a water-cooled shell-and-tube condenser. The honeycomb electric field 5 is composed of a hexagonal tubular electrode arrangement with a linear electrode in the center. The plate-line double-zone electric field 6 is composed of an ionization zone formed by a line electric field and an adsorption zone formed by a plate electric field.

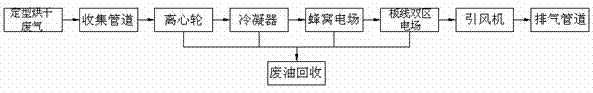

[0020] like figure 2 As shown, the steps of the condensing electrostatic treatment process for dyeing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com