Oat milk and preparation method thereof

A milk and oat technology, which is applied in the directions of milk preparations, dairy products, and applications, can solve the problems of low nutritional value, low digestion and absorption rate, and the taste, aroma and stability of milk need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

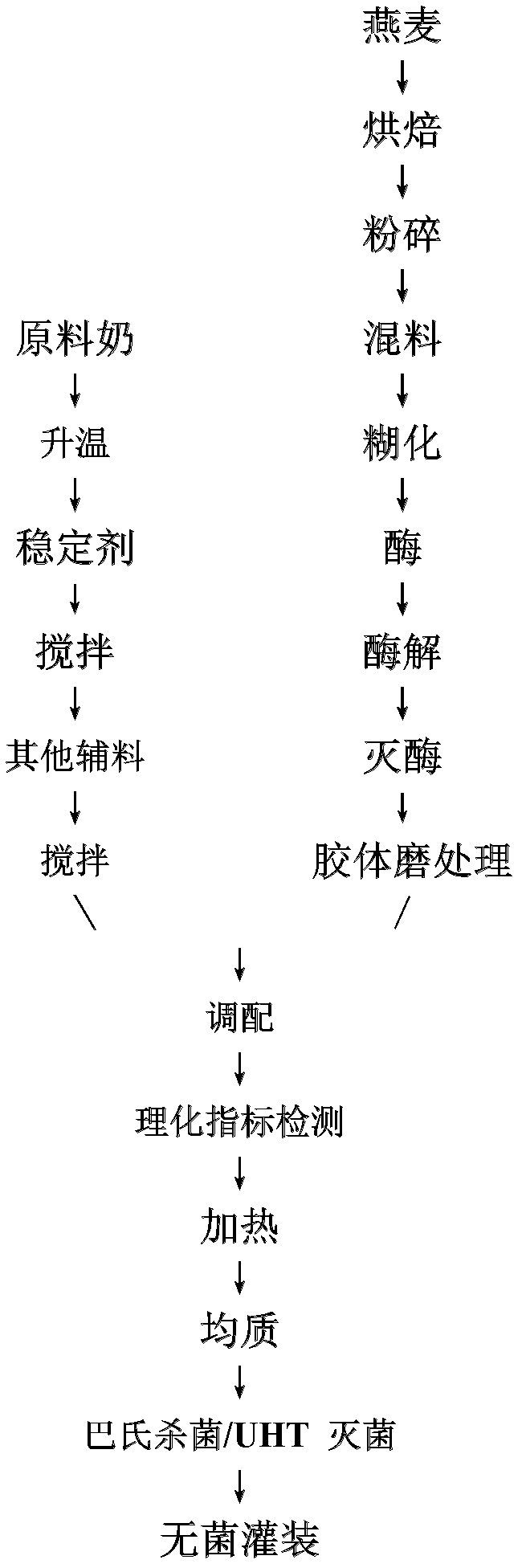

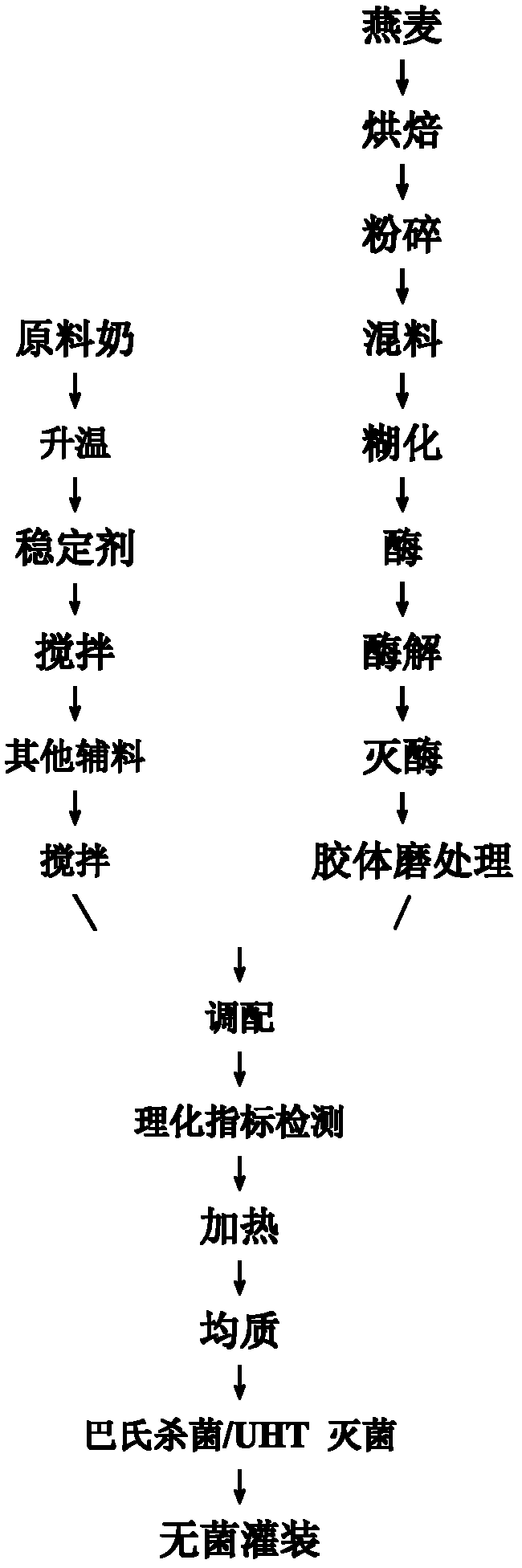

Method used

Image

Examples

Embodiment 1

[0044] Preparation of oat enzymatic hydrolyzate

[0045] 1) Bake 20kg of oatmeal in an oven at 60°C for 5 minutes;

[0046] 2) Use a pulverizer to pulverize oats to 10 meshes, and add them to the enzymatic hydrolysis tank;

[0047] 3) Add water at a mass ratio of material to liquid of 1:3, then heat up to 50°C and keep warm for 5 minutes;

[0048] 4) Add amylase in an amount of 0.01% of the total mass of oats and water in the above step 3), perform enzymatic hydrolysis for 5 minutes, and steam to inactivate the enzyme, and when the enzyme inactivation temperature is 137° C., incubate for 4 seconds;

[0049]5) Then, it is processed by a colloid mill, and the colloid mill is set to 20 mesh, and the oat enzymatic hydrolyzate is obtained. Preparation of oat milk

[0050] 1) Warm up 30kg of milk to 50°C, add 0.25kg of microcrystalline cellulose and 0.25kg of carrageenan, and stir thoroughly;

[0051] 2) Add 3kg white sugar, 2kg polydextrose, 2kg fructose syrup, 1kg honey, 1.5kg...

Embodiment 2

[0055] Preparation of oat enzymatic hydrolyzate

[0056] 1) Bake 70kg of oats in a frying pan at 280°C for 150 minutes;

[0057] 2) Utilize a mill to pulverize oats to 200 mesh, and add them to the enzymatic hydrolysis tank;

[0058] 3) Add water at a mass ratio of material to liquid of 1:30, then heat up to 100°C and keep warm for 150min;

[0059] 4) Add amylase in an amount of 0.5% of the total mass of oats and water in the above step 3), enzymatically hydrolyze for 150 minutes, and then inactivate the enzyme with steam or water bath, and when the temperature for inactivating the enzyme is 95° C.

[0060] 5) Then, it is processed by a colloid mill, and the colloid mill is set to 200 mesh, and the oat enzymatic hydrolyzate is obtained. Preparation of oat milk

[0061] 1) Warm up 80kg of milk to 80°C, add 0.15kg of guar gum and 0.35kg of carrageenan, and stir thoroughly;

[0062] 2) Add 1kg polydextrose, 1kg fructose syrup, 0.5kg honey, 1kg maltodextrin, 1kg fructo-oligosa...

Embodiment 3

[0066] Preparation of oat enzymatic hydrolyzate

[0067] 1) Bake 30kg of oats in an oven at 100°C for 65 minutes;

[0068] 2) Use a mill to pulverize oats to 100 mesh, and add them to the enzymatic hydrolysis tank;

[0069] 3) Add water at a mass ratio of material to liquid of 1:20, then heat up to 70°C and keep warm for 60min;

[0070] 4) Add cellulase in an amount of 0.3% of the total mass of oats and water in the above step 3), perform enzymatic hydrolysis for 70 minutes, and steam to inactivate the enzyme, and when the enzyme inactivation temperature is 90° C., carry out incubation for 15 minutes to inactivate the enzyme;

[0071] 5) Then, it is processed by a colloid mill, and the colloid mill is set to 160 mesh, and the oat enzymatic hydrolyzate is obtained.

[0072] Preparation of oat milk

[0073] 1) Heat 75kg of milk to 60°C, add xanthan gum, 0.1kg of sodium alginate, and 0.1kg of diglycerin fatty acid ester to 0.1kg, and stir thoroughly;

[0074] 2) Add 1kg white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com