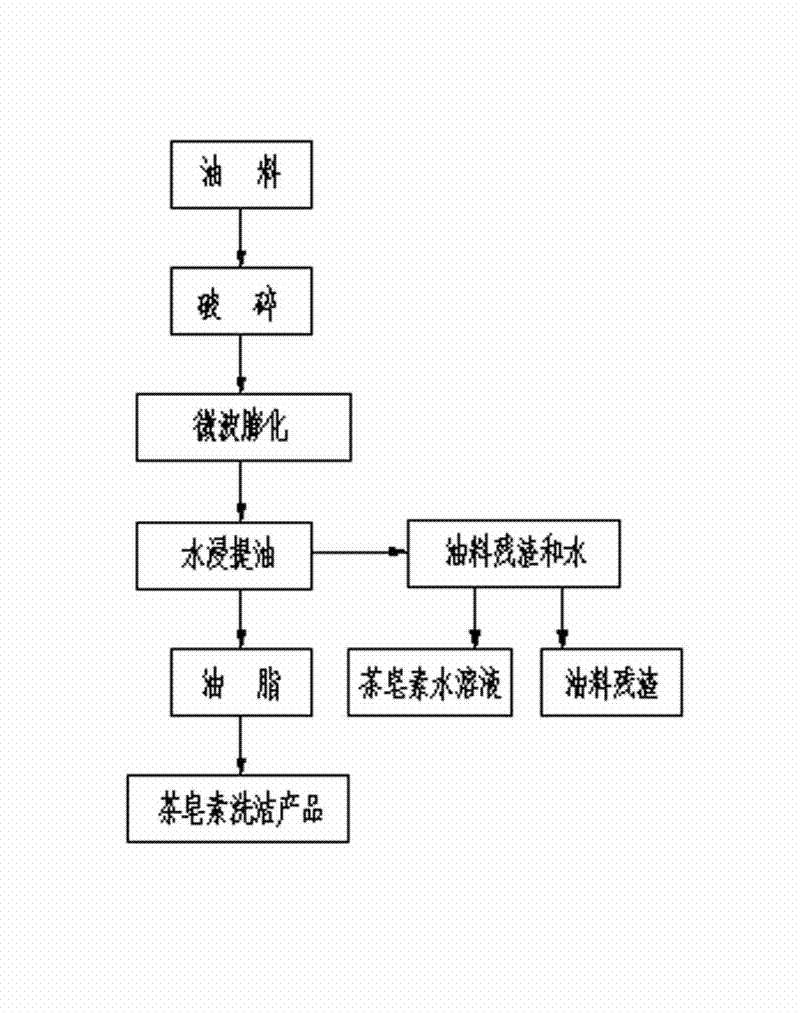

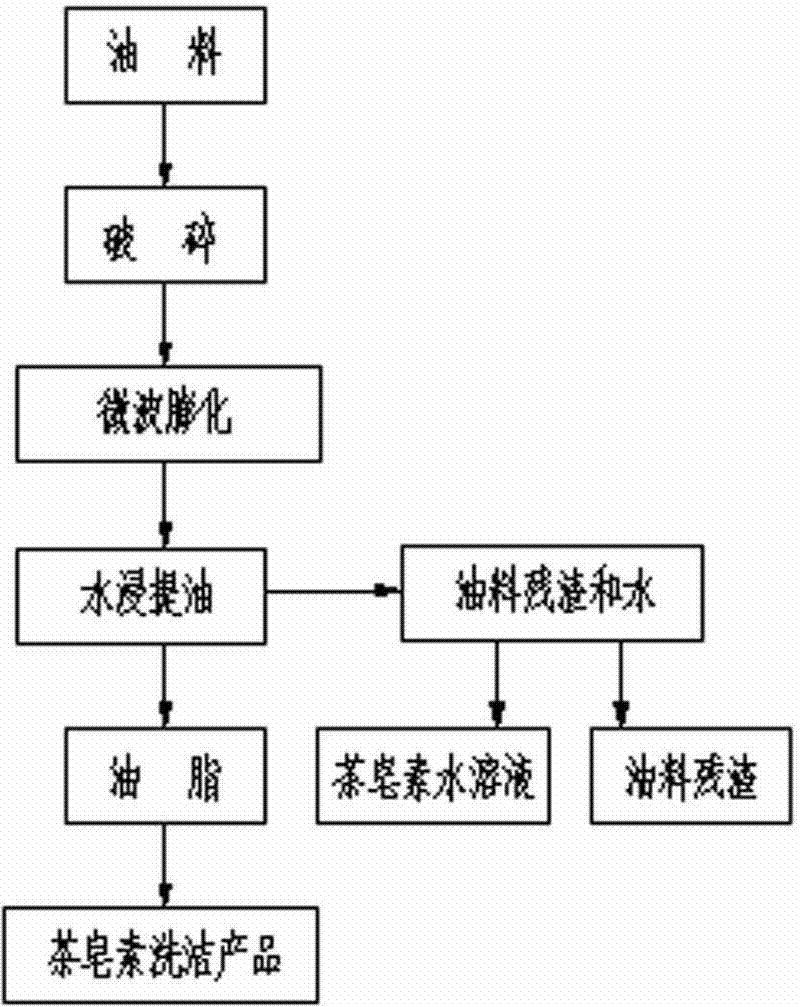

Method for microwave pretreatment and water extraction of edible oil

A technology of water extraction and pretreatment, which is applied in the direction of heating and preserving seeds, etc., can solve the problems of low oil yield of tea seed oil, restricting application, etc., and achieves the effect of simple process and improved oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Weigh 13.6 g of camellia oleifera seed dregs pretreated by microwave puffing, add 100 ml of 2.5% sodium chloride brine, stir in a water bath at 75°C for 1 hour, freeze and thaw the oil layer, and obtain 6.7 g of camellia oleifera seed oil.

Embodiment 2

[0040] Example 2: Weigh 5 grams of camellia oleifera seed dregs pretreated by microwave puffing, add 50 ml of 2.5% sodium chloride brine, mix well at room temperature, and place it. After the oil layer is frozen and thawed, 2.4 grams of camellia oleifera seed oil can be obtained.

[0041] In the present invention, in the presence of ethanol, ammonium bicarbonate and other puffing agents, the microwave puffing pretreatment of oil plants such as camellia seeds can fully destroy the cell structure of the oil plants, which is beneficial to improve the oil yield of the subsequent water immersion method; When extracting oil, adding NaCl and ethanol is beneficial to the rapid separation of oil and non-oil substances; oil extraction with water after microwave pretreatment is a green and safe production process; this production process has the advantages of simple process, low investment and easy industrial production features.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com