Porous vinylidene fluoride resin membrane and process for producing same

A technology of ethylene difluoride and its manufacturing method, which is applied in the field of 1, and can solve problems such as excessively large average pore size of porous membranes and maintenance of water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

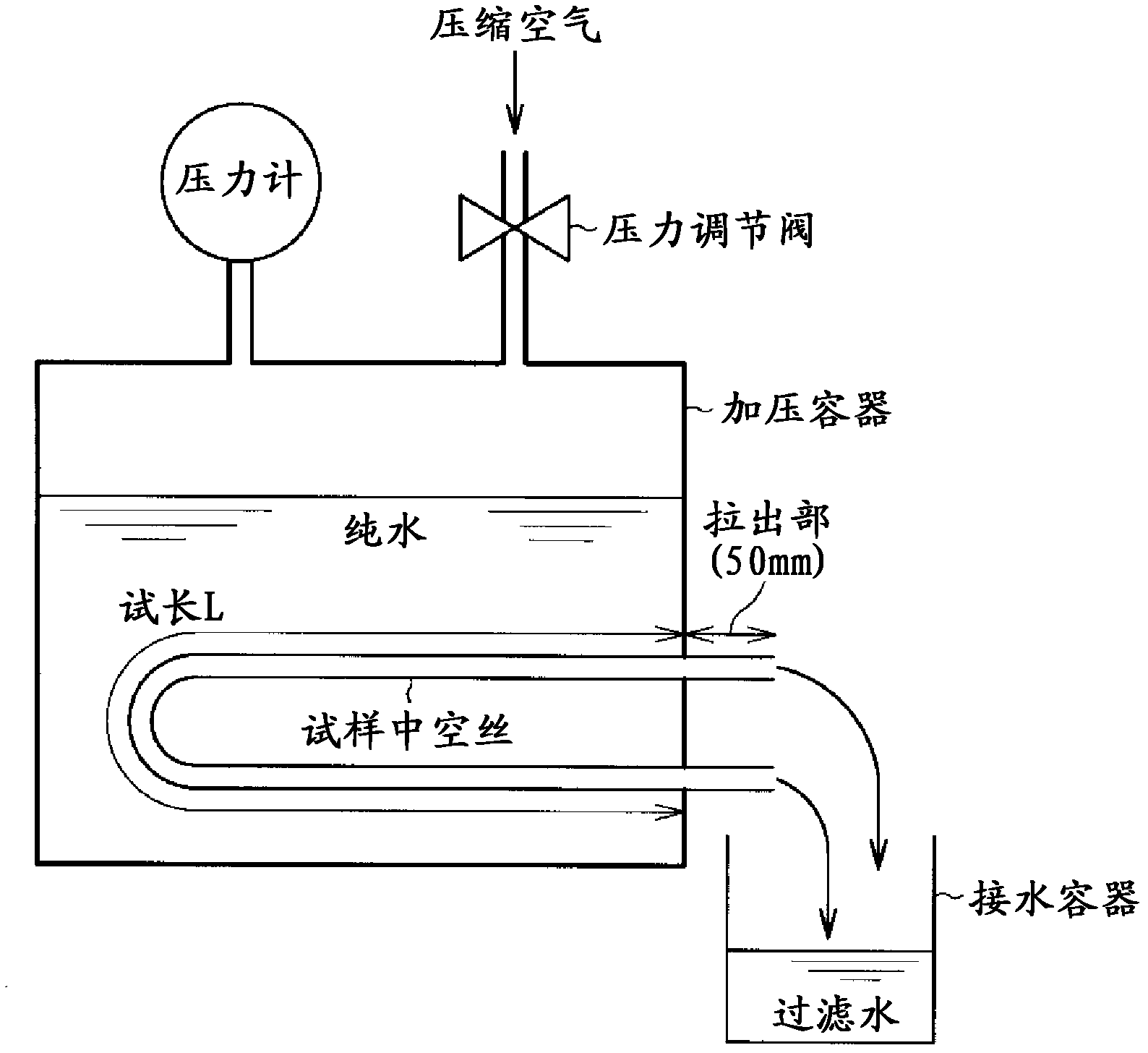

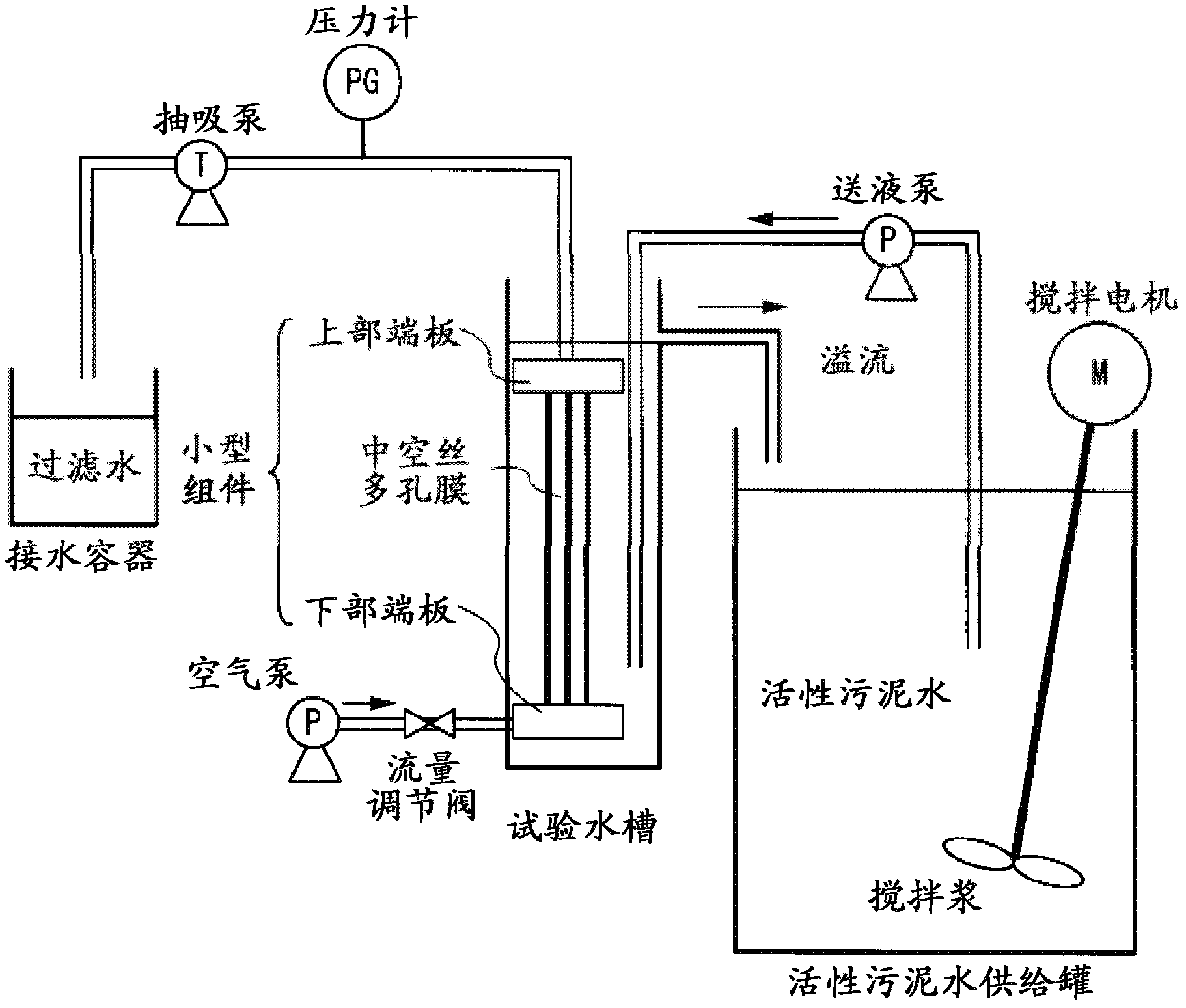

Method used

Image

Examples

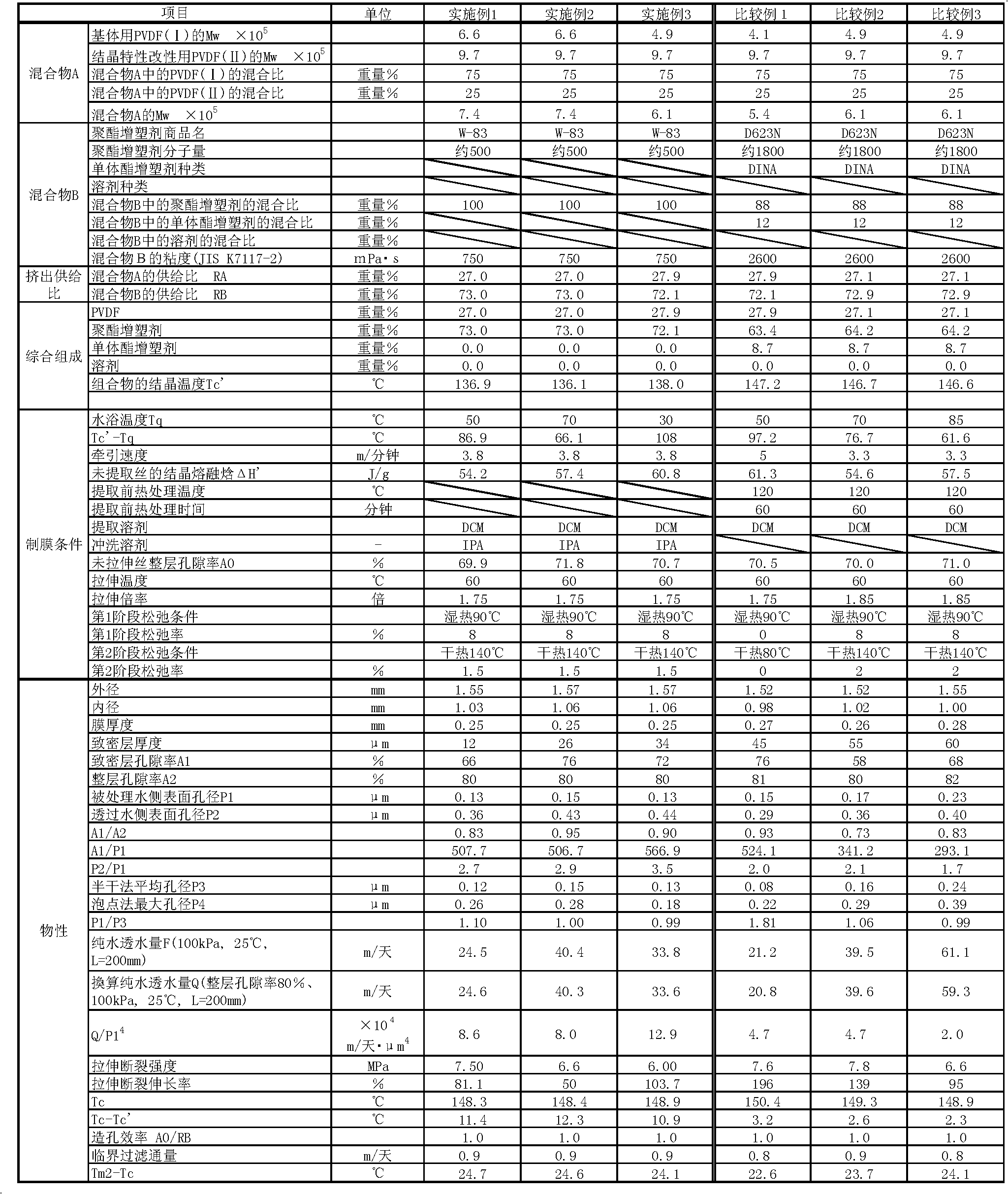

Embodiment 1

[0187] Using a Henschel mixer, the weight average molecular weight (Mw) was 6.6×10 5 The substrate is polyvinyl difluoride (PVDF-I) (powder) and Mw is 9.7×10 5 Polyvinylidene fluoride (PVDF-II) (powder) for modifying the crystallization properties of the above-mentioned polyvinyl difluoride (PVDF-II) is mixed according to the ratio of 75% by weight and 25% by weight respectively, and the obtained Mw is 7.4×10 5 PVDF mixture (mixture A; crystallization temperature Tc after film formation = 148.3° C.).

[0188] As the plasticizer, a polyester-based plasticizer (polyester of dibasic acid and diol whose terminal is blocked with benzoic acid; "W-83" manufactured by DIC Co., Ltd., with a number average molecular weight of about 500, according to JIS K7117 -2 (cone-plate type rotational viscometer) measured viscosity at 25° C. is 750 mPa·s).

[0189] Using a co-rotating intermeshing twin-screw extruder (“TEM-26SS” manufactured by Toshiba Machine Co., Ltd., screw diameter 26mm, L / D=...

Embodiment 2

[0198] Except having changed the cooling water bath temperature Tq after melt extrusion into 70 degreeC, it carried out similarly to Example 1, and obtained the polyvinylidene fluoride type hollow fiber porous membrane of this invention.

Embodiment 3

[0200] Use Mw of 4.9×10 5 The polyvinylidene fluoride was used as PVDF-I to obtain PVDF mixture A (crystallization temperature Tc=147.9°C), and the cooling water bath temperature Tq after melt extrusion was changed to 30°C. In the same manner, the polyvinylidene fluoride-based hollow fiber porous membrane of the present invention was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com