Temperature measuring device of machine tool

A temperature measurement and machine tool technology, applied in the direction of measuring device, thermometer, measuring heat, etc., can solve the problems of the influence of machine tool movement, the failure of temperature monitoring, the disconnection of the connecting line, etc., to achieve a convenient and fast fixing method, improve temperature measurement accuracy, and The effect of temperature monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

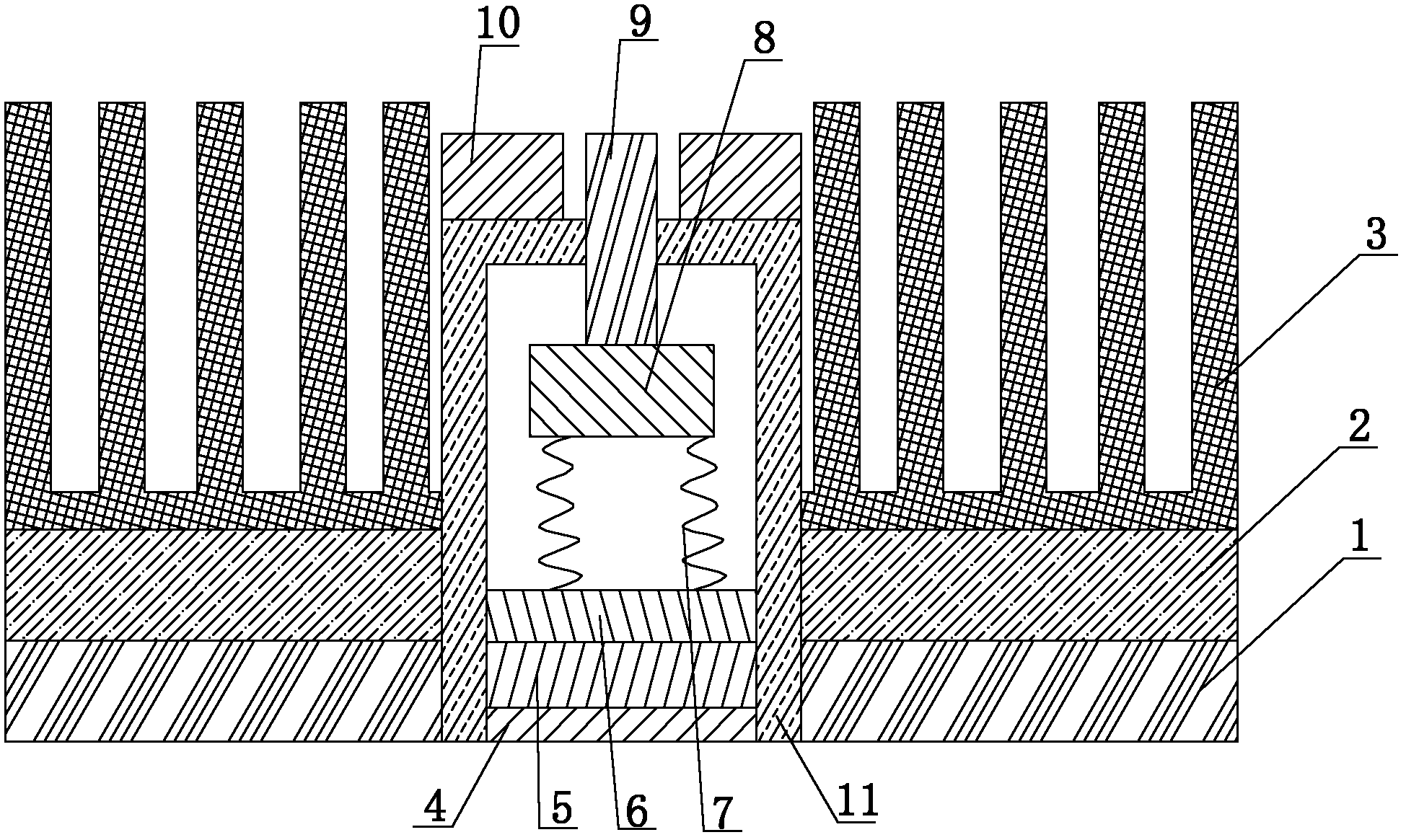

[0037] Such as figure 1 Shown, a kind of machine tool temperature measuring device comprises:

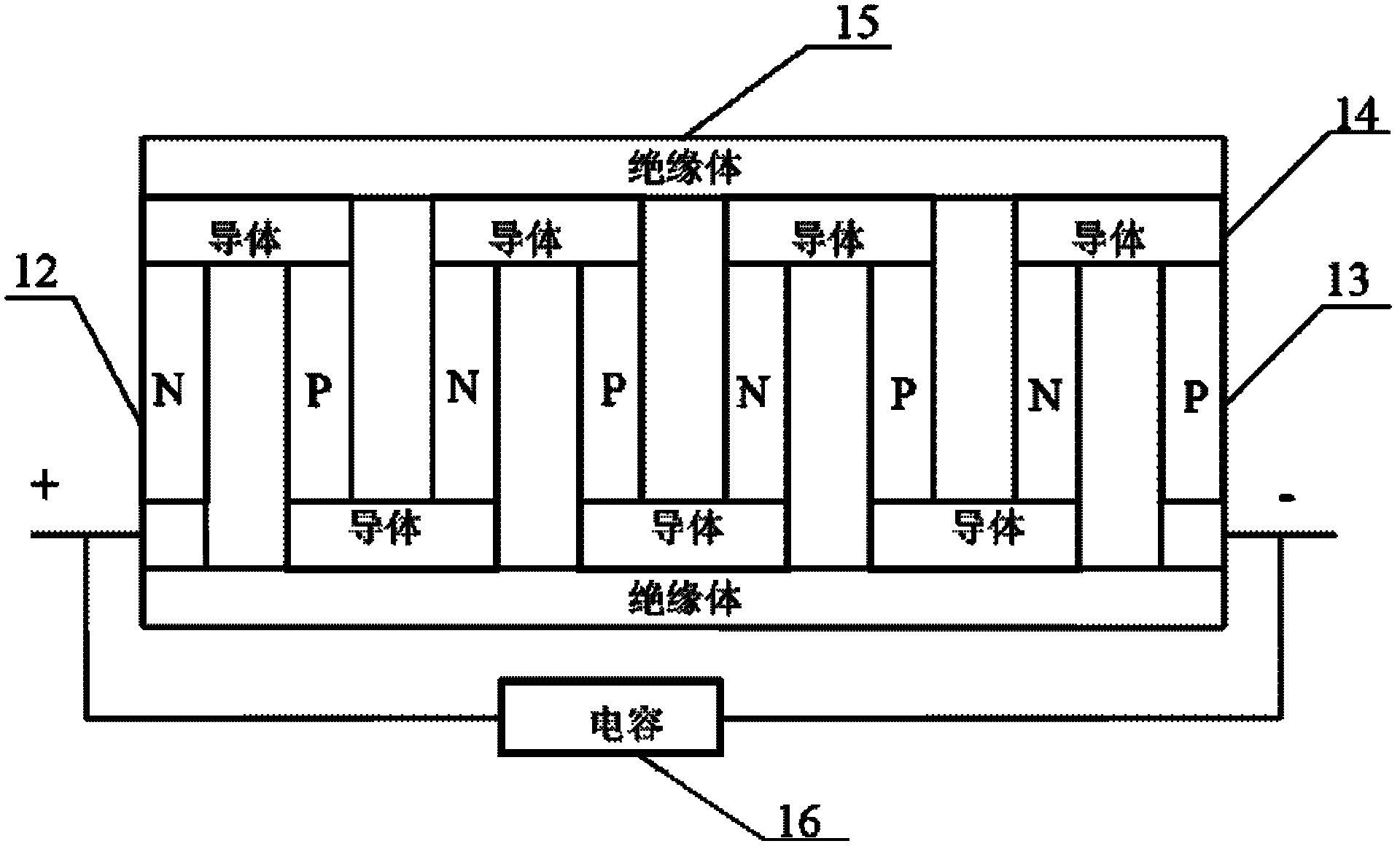

[0038] The magnetic connector 1, the magnetic connector 1 is specifically selected from the magnetic steel mainly composed of NdFeB metal alloy, one side of the magnetic connector 1 is used for fixed connection with the surface of the machine tool to be tested, and the other side of the magnetic connector 1 is fixed with The thermoelectric power generation module 2, the side of the thermoelectric power generation module 2 connected to the magnetic connector 1 is used as the high temperature end of the thermoelectric power generation module 2, and the side of the thermoelectric power generation module 2 away from the magnetic connector 1 is fixed with a heat sink 3, which is used for the heat sink 3 Dissipate heat at the low temperature end of the thermoelectric power generation module 2 . The magnetic connector 1, the thermoelectric power generation module 2 and the heat sink 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com