Superconducting heat pipe-type heat exchanger and liquid filling method thereof

A tubular heat exchanger and superconducting technology, which is applied to solar collectors, solar collectors using working fluids, heating devices, etc. , many non-condensable gases, etc., to achieve the effect of high heat exchange efficiency, easy on-site installation, and fast heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

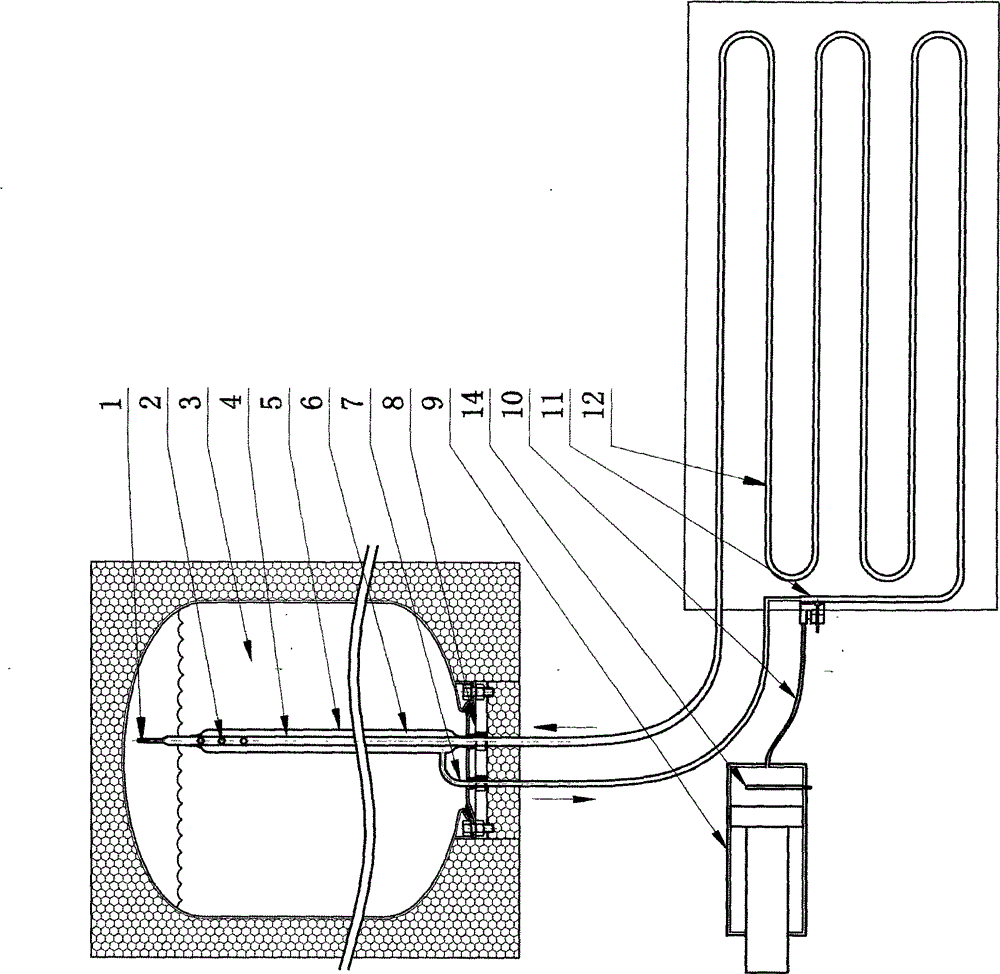

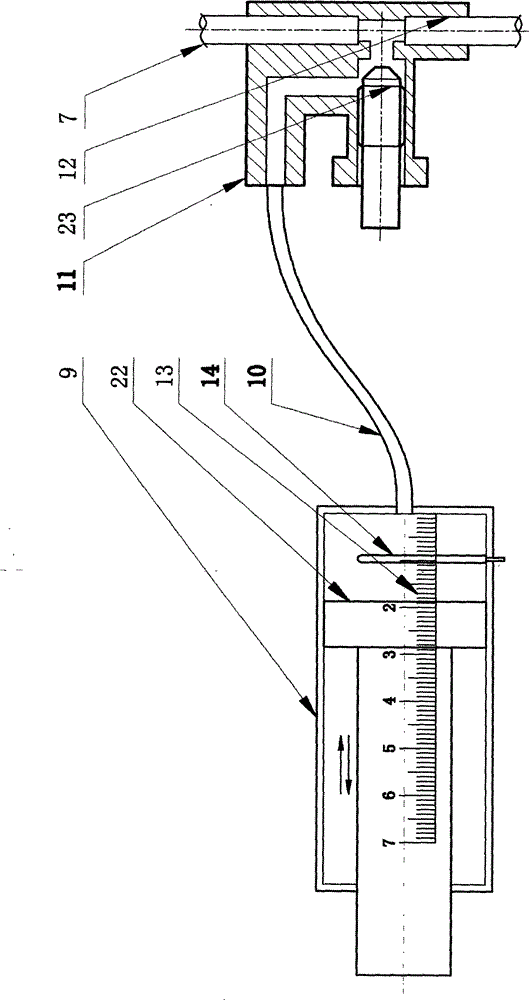

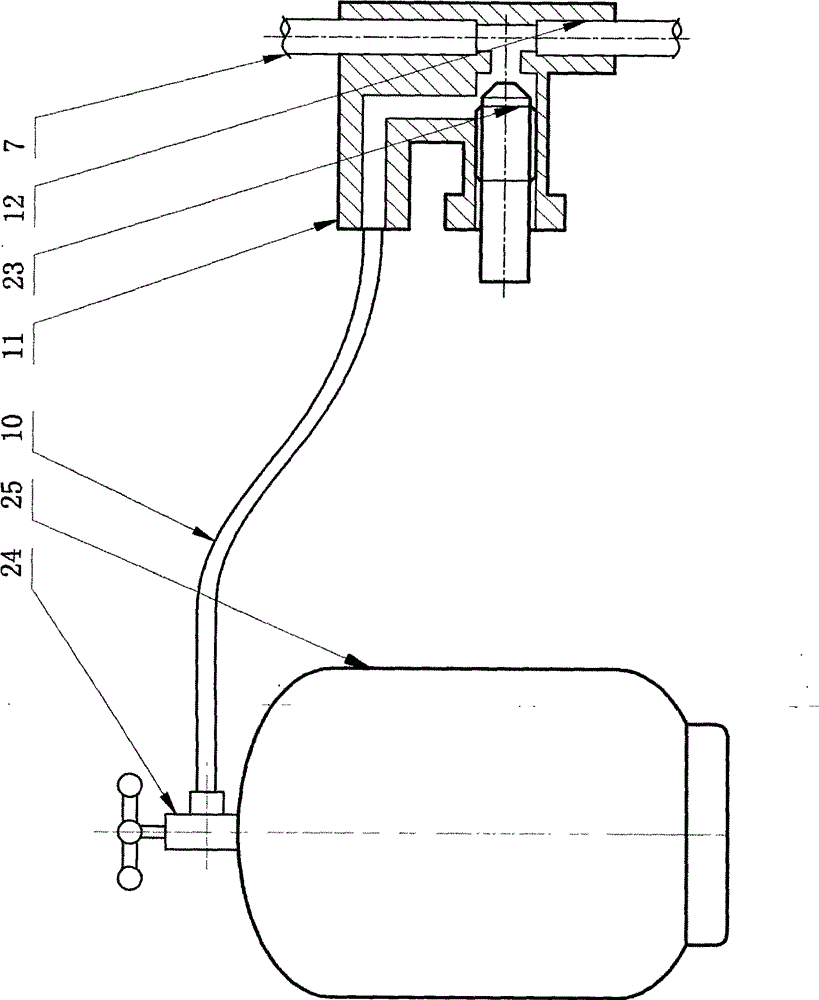

[0017] Depend on Figures 1 to 3 It can be seen that the superconducting heat pipe heat exchanger of the present invention is composed of a hot air flow pipe 4, an overflow port head 1, a condensation sleeve 5, a gas-liquid hole 2, a condensation chamber 6, a return pipe 7, a liquid-filled three-way valve 11, a collector Heater 12, liquid filling device constitute. The lower end of the hot air flow pipe 4 and the return pipe 7 of the superconducting heat pipe heat exchanger are installed and sealed on the water tank cover 8 and the wall of the water tank at the bottom of the thermal insulation water tank, and the hot air flow pipe 4 from the upper end of the condensation sleeve 5 to the overflow head 1 There is at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com