Corrugated guardrail plate

A kind of guardrail board and corrugated board technology, which can be applied to fences, stepped structures, buildings, etc., can solve the problems of poor impact energy absorption, easy corrosion, and low elastic modulus of all-plastic materials, so as to reduce the impact force and prolong the contact time. , the effect of reducing the impact peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

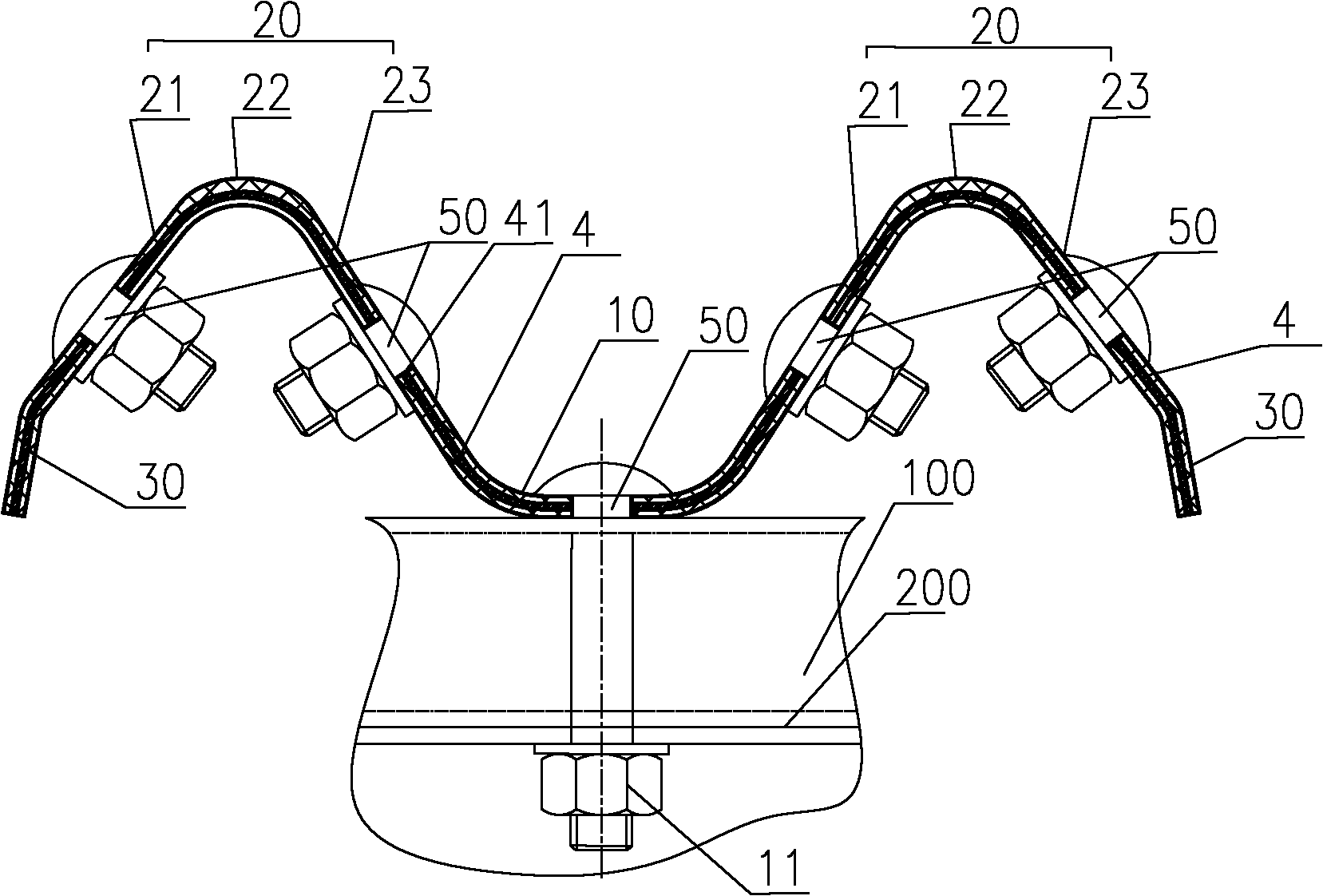

[0081] Embodiment 1, as figure 1In the shown corrugated guardrail board, the base plate 10 is a flat thermoplastic composite plate, and a plurality of connecting holes 50 are spaced apart on the central axis of the base plate 10, and bolts 11 are installed in the connecting holes 50 to connect the anti-blocking block 100 and the column. 200 fixedly connected together. Corrugated plates 20 are respectively extended at both ends of the substrate 10 in the lateral direction, the substrate 10 and the corrugated plate 20 are integrally structured, and the corrugated plates 20 protrude toward the same side of the substrate 10 and exceed the substrate 10. The base plate 10 smoothly transitions to the corrugated plate 20; both the base plate 10 and the corrugated plate 20 extend in the length direction of the guardrail, the base plate 10 and the corrugated plate 20 are thermoplastic composite plates, and the thermoplastic composite plate includes a reinforced skeleton 4 , the reinfor...

Embodiment 2

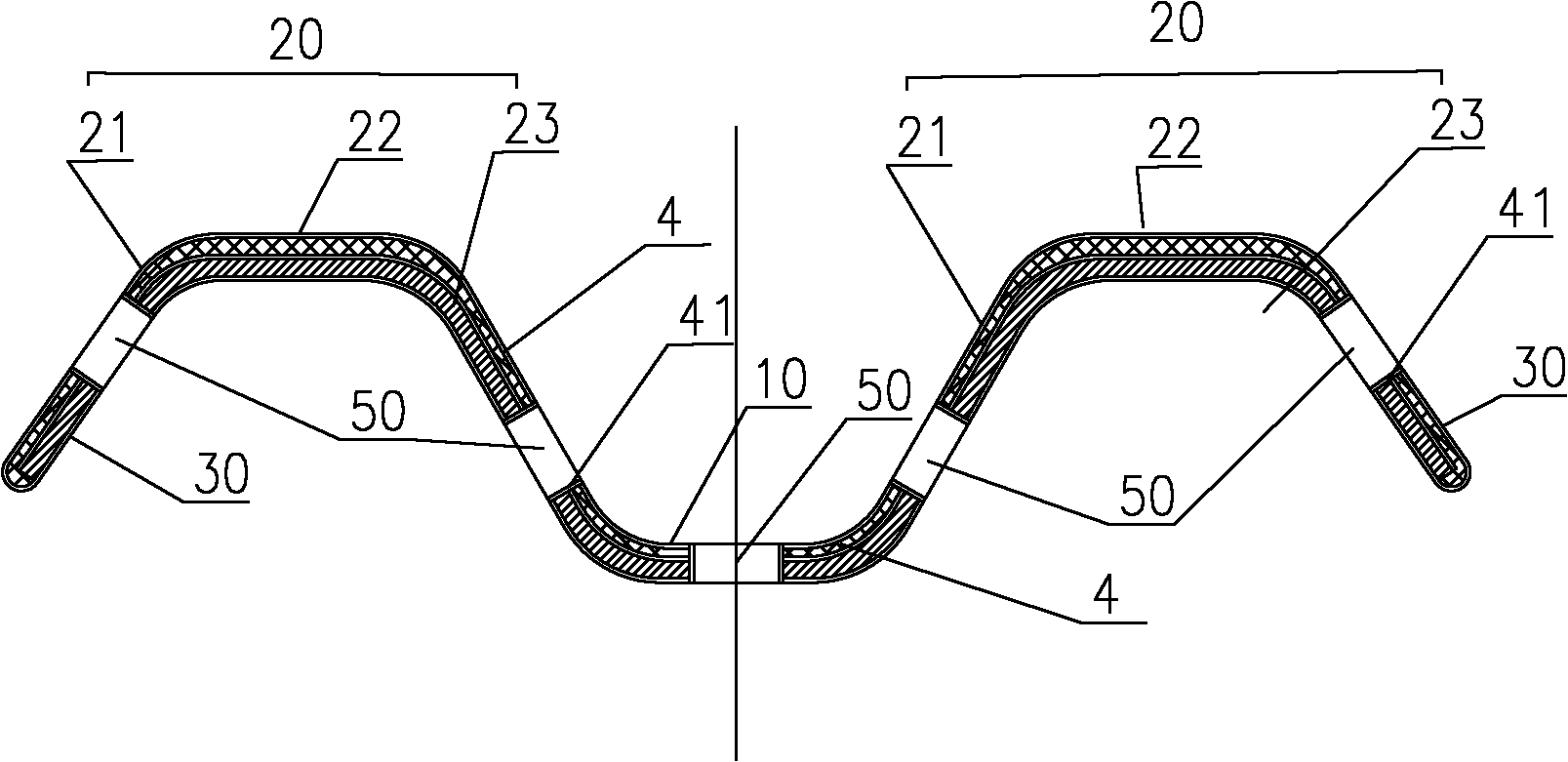

[0087] Embodiment 2, as figure 2 The shown guardrail is an improvement made on the basis of Embodiment 1, that is, the top plate 22 of the corrugated plate 20 is changed from an outwardly protruding arch to a straight shape, and the thickness of the buffer layer in the thermoplastic material layer in the top plate 22 is that of other positions. 1.5 to 2 times. In this embodiment, no flange plate 30 is provided, and the thermoplastic material layer at the edge of the outer wall plate 21 is semi-cylindrical. The rest of the structure is the same as that of Embodiment 1 and will not be repeated here.

Embodiment 3

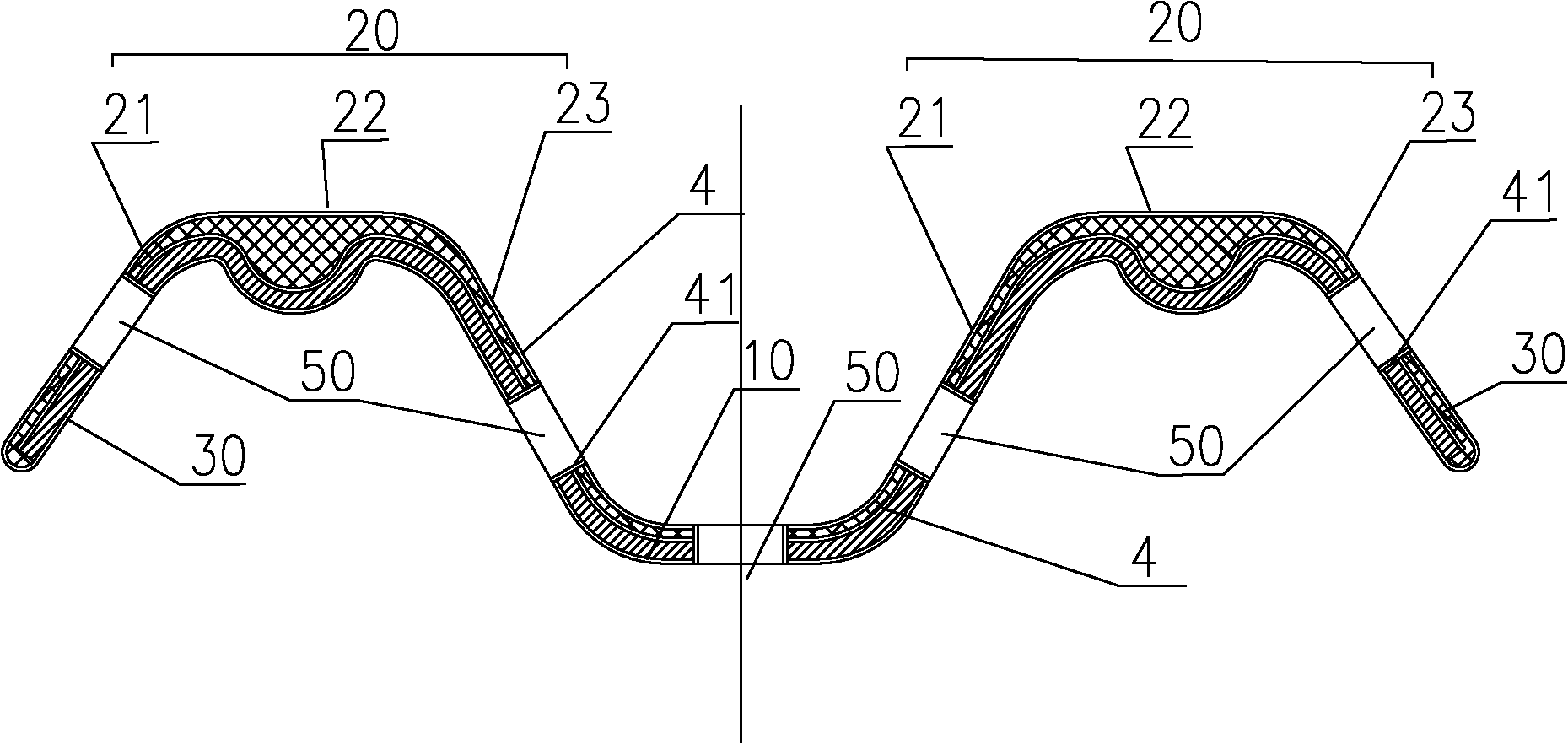

[0088] Embodiment 3, as image 3 The guardrail shown is an improvement on the basis of Embodiment 2, the base plate 10 remains unchanged, and the reinforcing skeleton 4 in the top plate 22 of the corrugated plate 20 is M-shaped or V-shaped. The depression is filled up by the buffer layer of the thermoplastic material layer, and the thickness of the buffer layer here is 1.5 to 2 times that of other positions. Such a structure of the top plate 22 greatly increases the thickness of the thermoplastic material layer on the outside of the reinforcement framework 4 at the top plate 22 , which strengthens the flexibility and cushioning capacity of the top plate 22 . The rest of the structure is the same as that of Embodiment 2 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com