Press felt for papermaking

A technology for press felts and paper, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of disturbing the stability of papermaking operations, increasing the number of operating procedures, and accelerating the wear of the base fabric, so as to avoid substantial changes in physical properties. , to avoid the effect of increasing the number of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

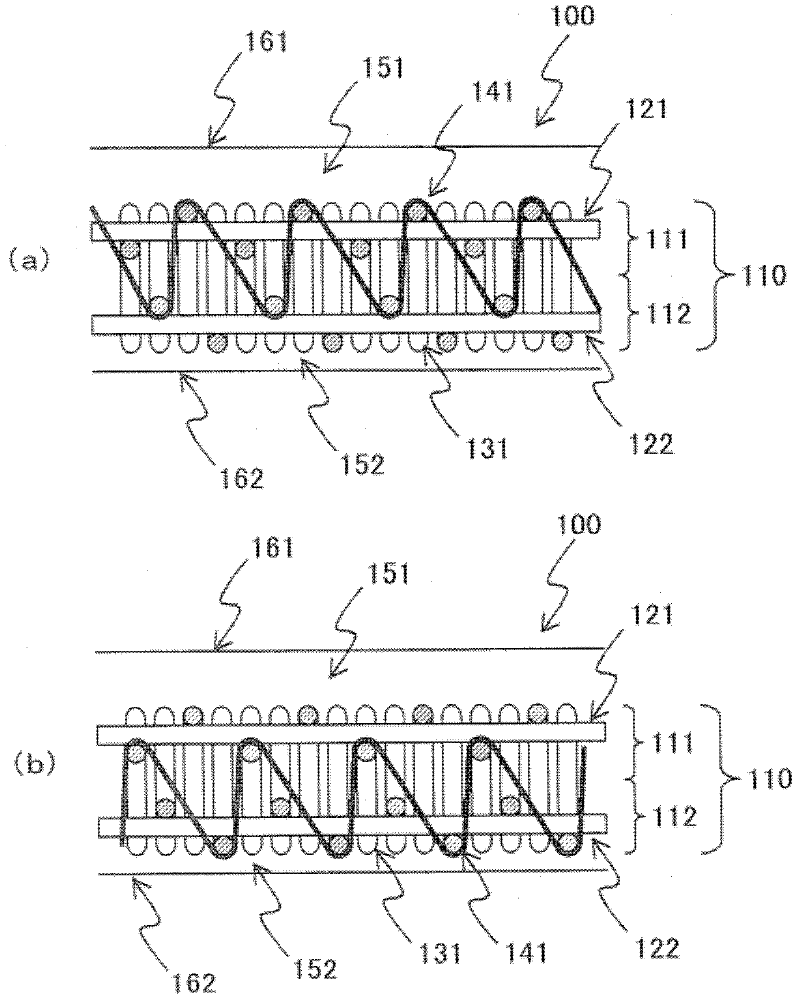

[0063] Hereinafter, embodiments of the present invention will be described based on the drawings. figure 1 (a), figure 1 (b) is a longitudinal cross-sectional view showing an example of the press felt for papermaking of the present invention. The felt 100 is formed by laminating and integrating the front bonding fiber layer 151 on the wet paper side 161 of the base fabric 110 by the needle punching method, and forming the back bonding fiber layer 152 by laminating and integrating on the roll side 162 of the bottom 110 by the needle punching method. constitute. The base fabric 110 has the following warp double structure: the ground warp yarns 121 on the wet paper side and the ground warp yarns 122 on the roll side overlap in the thickness direction, and the wet paper side layer 111 and the roll side layer 111 and the roll side are respectively composed of the upper and lower ground warp yarns 121 and 122. Layers 112 are stacked.

[0064] As the raw materials of the ground wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com