A kind of preparation method of white electrochromic device

A technology of electrochromic devices and electrochromic layers, applied in the field of electronic information, can solve the problems of reducing the color of electroluminescent devices, lifetime luminous efficiency, low device efficiency, poor transparency of inorganic YAG fluorescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

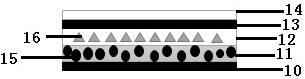

[0034] The invention discloses a preparation method of a white electrochromic device; it comprises a polyacrylamide transparent conductive material, an electrochromic device structure, and an electroluminescent device structure; the electrochromic device is prepared on one side of the polyacrylamide conductive layer material through a printing and spraying process. The electrochromic device structure is prepared on the other side; the electrochromic device structure can realize the conversion of absorption spectrum from transparent to 530-660nm band under the drive of DC voltage, and the electroluminescent device structure can be driven by AC voltage It can realize the blue-green emission with emission spectrum of 500-520nm; by adjusting the emission spectrum and color-changing wavelength, the mutual conversion between blue-green light and white emission of the light-emitting device can be realized.

[0035] The preparation method of a white photochromic device according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com