X70-degree large deformation resisting pipeline steel plate with excellent tenacity and preparation method for pipeline steel plate

A technology of anti-large deformation and steel plate, applied in X70 grade anti-large deformation pipeline steel plate and its preparation, natural gas transmission pipeline engineering construction, oil field, can solve the problems of low impact toughness and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

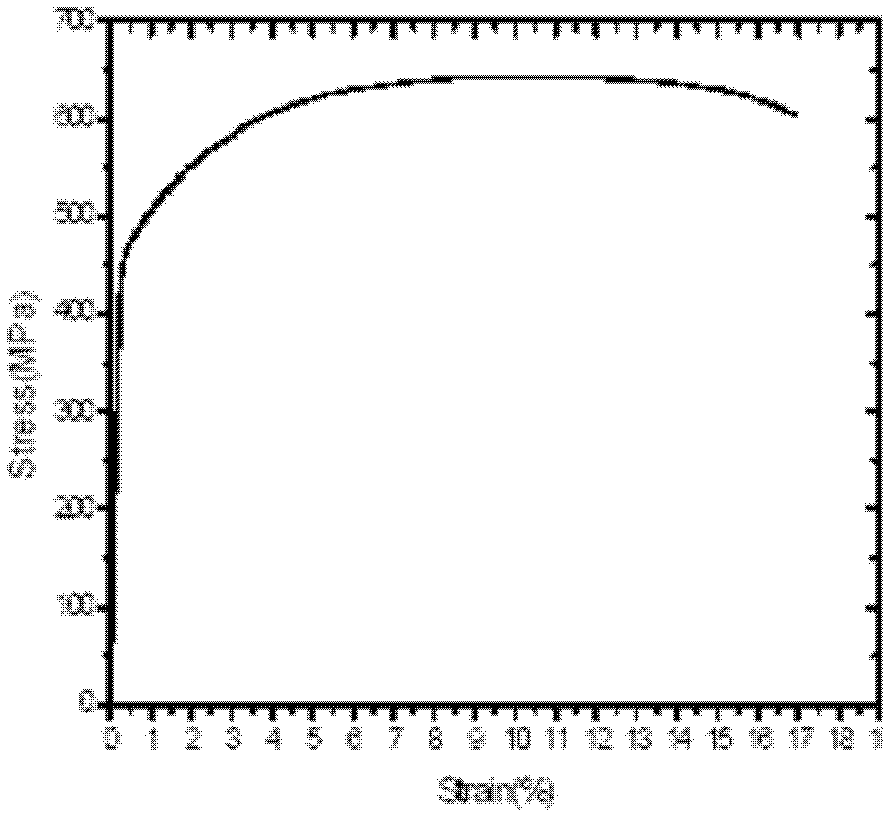

Embodiment 1

[0028] The product specification is a steel plate with a thickness of 21mm and a width of 3110mm, the thickness of the continuous casting slab is 300mm, the casting speed is 0.80m / min, and the dynamic soft reduction technology is adopted. Slab heating temperature: 1150°C, heating time 4 hours; the first stage controlled rolling starts at 995°C and ends at 980°C. The second stage of controlled rolling starts at 885°C and ends at 840°C. Waiting for the temperature for the second time, the thickness of the billet to be warmed is 26mm. The starting temperature of the third stage of controlled rolling is 765°C, and the ending temperature is 735°C; after rolling, it quickly enters the water cooling area, the temperature of the water entering is 720°C, the cooling rate of the first stage is 4°C / s, and the final cooling temperature is 630°C, the second stage The cooling rate is 20°C / s, and the final cooling temperature is 410°C. The comprehensive mechanical properties of the steel p...

Embodiment 2

[0030] The product specification is a steel plate with a thickness of 21mm and a width of 3110mm, the thickness of the continuous casting slab is 300mm, the casting speed is 0.80m / min, and the dynamic soft reduction technology is adopted. Slab heating temperature: 1160°C, heating time 4 hours; the first stage controlled rolling start temperature 990°C, end temperature 970°C. The second stage of controlled rolling starts at 880°C and ends at 830°C. Wait for the temperature for the second time, and the thickness of the billet to be warmed is 30mm. The starting temperature of the third stage of controlled rolling is 760°C, and the ending temperature is 730°C; after rolling, it quickly enters the water cooling area, the temperature of the water entering is 710°C, the cooling rate of the first stage is 5°C / s, and the final cooling temperature is 620°C, the second stage The cooling rate is 22°C / s, and the final cooling temperature is 420°C. The comprehensive mechanical properties ...

Embodiment 3

[0032] The product specification is a steel plate with a thickness of 17.5mm and a width of 3118mm, the thickness of the continuous casting slab is 250mm, the casting speed is 0.90m / min, and the dynamic soft reduction technology is adopted. Slab heating temperature: 1190°C, heating time 4 hours; the first stage controlled rolling start temperature 990°C, end temperature 970°C. The second stage of controlled rolling starts at 870°C and ends at 825°C. Waiting for the temperature for the second time, the thickness of the billet to be warmed is 26mm. The starting temperature of the third stage of controlled rolling is 765°C, and the ending temperature is 730°C; after rolling, it quickly enters the water cooling area, the temperature of the water entering is 710°C, the cooling rate of the first stage is 10°C / s, and the final cooling temperature is 600°C, the second stage The cooling rate is 25°C / s, and the final cooling temperature is 450°C. The comprehensive mechanical propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com