Preparing method and application of red light materials based on ZnO doped with Co

A technology of red light and doping source, applied in luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of difficulty in obtaining red light materials, scarcity of red light materials, harmful preparations for human body, etc., and achieve no thermal stability. Poisonous, easy-to-implement, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

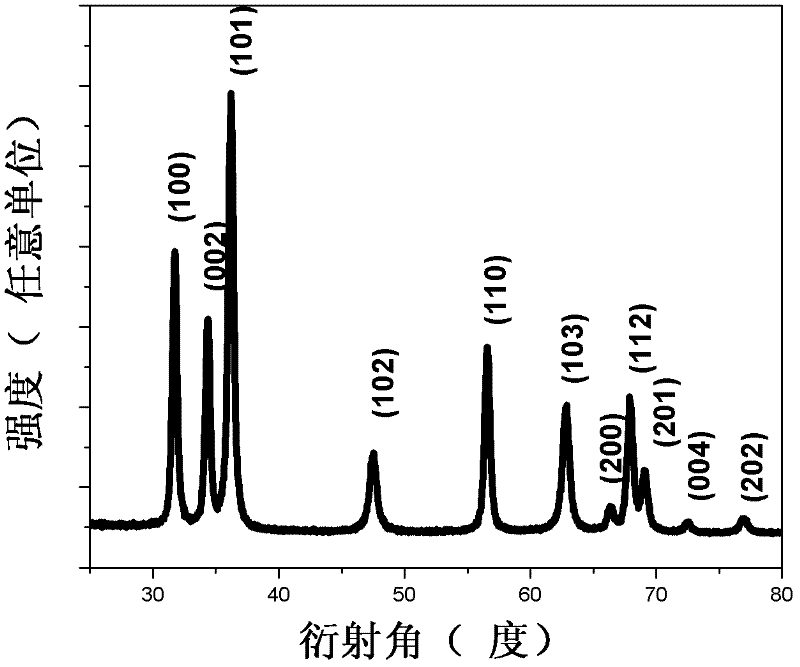

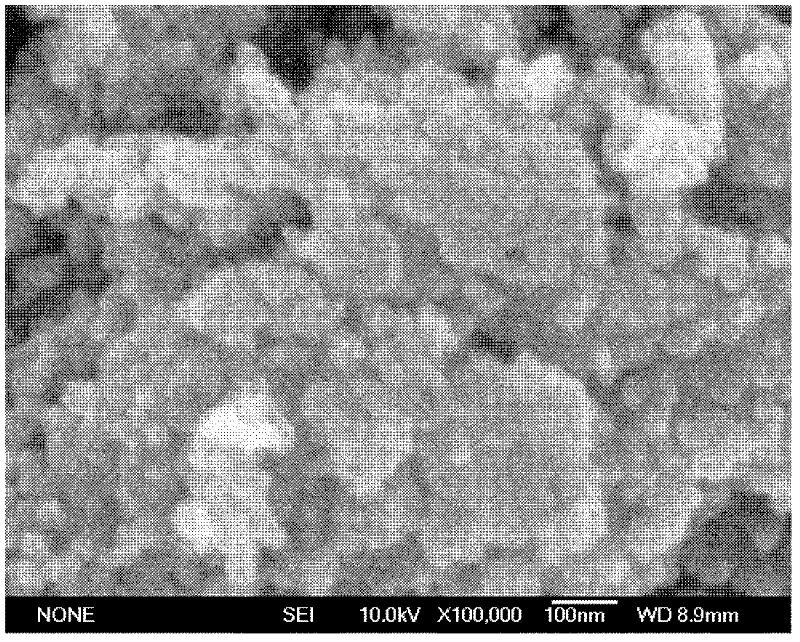

[0024] A method for preparing a red-light material based on Co-doped ZnO, the steps are as follows:

[0025] 1) Weigh 1.3g of zinc acetate and 0.04g of cobalt acetate, mix and dissolve in 60ml of absolute ethanol, and ultrasonically dissolve for 30 minutes;

[0026] 2) Weigh 1.6g of sodium hydroxide, dissolve it in 40ml of absolute ethanol, and ultrasonically dissolve it for 30 minutes;

[0027] 3) Pour the sodium hydroxide solution prepared in step 2 into the mixed solution of zinc acetate and cobalt acetate prepared in step 1, magnetically stir for 30 minutes, then pour the resulting mixed solution into a three-necked bottle, and put the three-necked bottle Put it into a water bath, connect the condensing tube to reflux, heat in a water bath at 90°C and magnetically stir for 2 hours, and finally centrifuge the solution;

[0028] 4) The separated precipitate was washed three times with deionized water and absolute ethanol respectively, and the precipitate was dried in a forc...

Embodiment 2

[0035] A method for preparing a red-light material based on Co-doped ZnO, the steps are as follows:

[0036] 1) Weigh 2.4g of zinc acetate and 0.028g of cobalt acetate, mix and dissolve in 110ml of absolute ethanol, and ultrasonically dissolve for 30 minutes;

[0037] 2) Weigh 2g of sodium hydroxide and dissolve it in 50ml of absolute ethanol, and ultrasonically dissolve it for 30 minutes;

[0038] 3) Pour the sodium hydroxide solution prepared in step 2 directly into the mixed solution of zinc acetate and cobalt acetate prepared in step 1 and stir it magnetically for 30 minutes, then place the resulting mixed solution in a water bath at 80° C. Stir and fully react for 2 hours, and finally centrifuge the solution;

[0039] 4) The separated precipitate was washed three times with deionized water and absolute ethanol respectively, and the precipitate was placed in a blast drying oven at 40° C. to dry to obtain a Co-doped ZnO luminescent material.

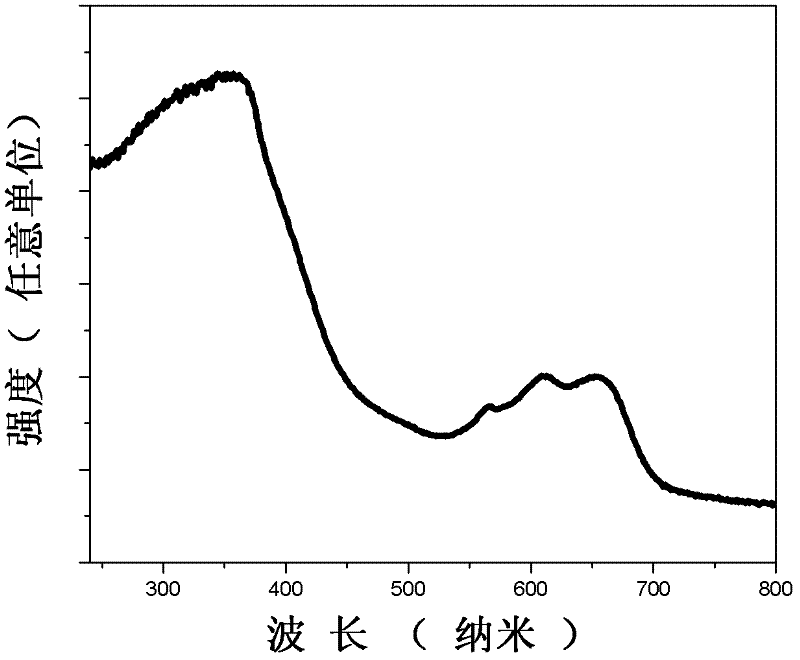

[0040] The luminescent prope...

Embodiment 3

[0043] A method for preparing a red-light material based on Co-doped ZnO, the steps and process conditions are the same as in Example 1, except that the sodium hydroxide in step 2 is changed to potassium hydroxide of the same quality.

[0044] The luminescent properties of the Co-doped ZnO red light material prepared in this example are similar to those in Example 1.

[0045] The Co-doped ZnO material is used as an inorganic functional layer, the method is basically the same as in Example 1, the difference is that polyethylene glycol is used as a dispersant, and the Co-doped ZnO nanomaterial is dispersed in a polyethylene glycol solvent Co-doped ZnO polyethylene glycol solution was formed, and then the Co-doped ZnO polyethylene glycol solution was spin-coated on the zinc gallium oxide (GZO) transparent polyethylene plastic substrate that had been ultrasonically cleaned and dried. The GZO electrode is the anode of the device with a resistance of 20Ω / □; the silver-lithium alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com