Polymer dielectric substance and preparation method thereof

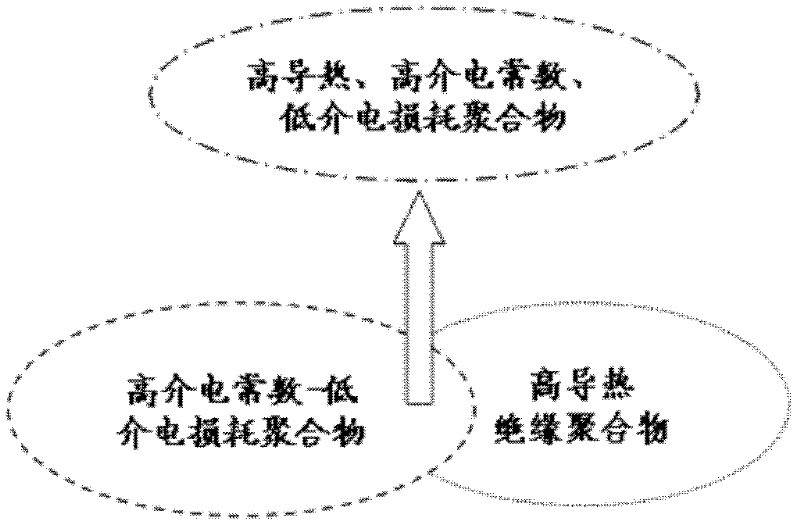

A technology of dielectric materials and polymers, applied in the direction of fixed capacitor dielectrics and components of fixed capacitors, to achieve the effect of simple process, good processing performance and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

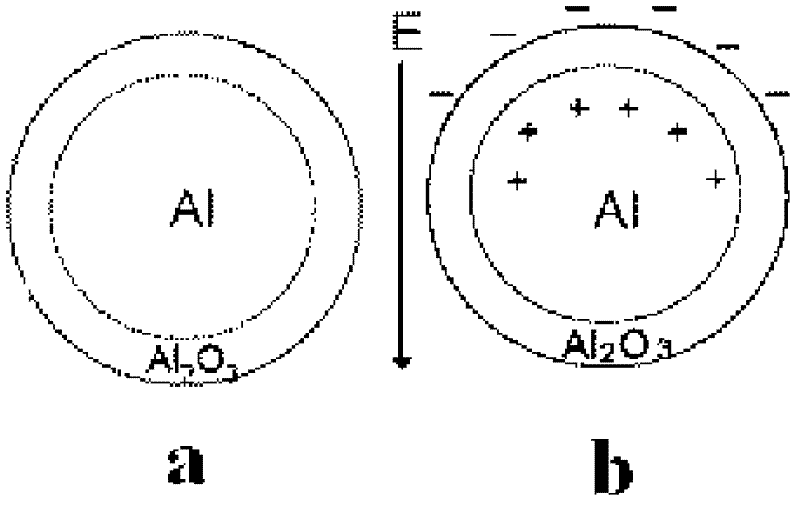

Method used

Image

Examples

Embodiment 1

[0033] The main formula of the high dielectric constant-low dielectric loss polymer dielectric with good thermal conductivity involved in the present invention is as follows (weight ratio):

[0034] Polyvinylidene fluoride resin (PVDF) 36%

[0035] Composite structure aluminum particles (1-2μm) 60%

[0036] Carbon nanofiber (diameter: 100-200nm) 4%

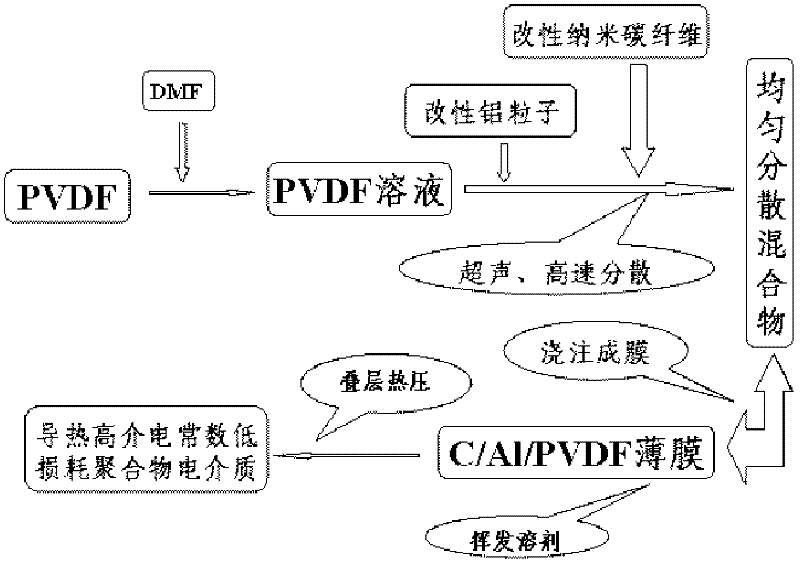

[0037] A method for preparing a high dielectric constant-low dielectric loss polymer dielectric with such thermal conductivity, which is prepared by surface modification of carbon nanofibers, surface modification of composite structure aluminum particles, mixed fillers and polyvinylidene fluoride resin composite materials3 Partial composition:

[0038] (1) Surface modification of carbon nanofibers

[0039]Take 20g of carbon nanofibers, immerse in 40% hydrofluoric acid for about 24 hours for oxidation treatment, after immersion, filter to remove impurities, wash with deionized water about 10 times until the pH value is about 6. ...

Embodiment 2

[0045] Polyvinylidene fluoride resin (PVDF) 38%

[0046] Composite structure aluminum particles (1-2μm) 57.8%

[0047] Carbon nanofiber (diameter: 100-200nm) 4.2%

[0048] Preparation:

[0049] (1) Surface modification of carbon nanofibers

[0050] Take 20g of carbon nanofibers (diameter: 100-200nm), soak in hydrofluoric acid with a concentration of 40% for about 25h for oxidation treatment, after soaking, filter to remove impurities, wash with deionized water for about 8 times until the pH value is about 6. The carbon nanofibers from which impurities have been removed are placed in a vacuum oven and dried at 80° C. for about 28 hours, and are ready for use.

[0051] (2) Surface modification of aluminum particles with composite structure

[0052] Take about 100g of aluminum particles (1-2μm) into a 500ml three-neck flask, add 140ml of absolute ethanol, stir for 10 minutes, and then ultrasonicate the liquid mixture for 40 minutes. At the same time, weigh the silane coupli...

Embodiment 3

[0056] Polyvinylidene fluoride resin (PVDF) 40%

[0057] Composite structure aluminum particles (1-2μm) 55.5%

[0058] Carbon nanofiber (diameter: 100-200nm) 4.5%

[0059] Preparation:

[0060] (1) Surface modification of carbon nanofibers

[0061] Take 20g of carbon nanofibers (diameter: 100-200nm), soak in 40% hydrofluoric acid for about 26h oxidation treatment, after soaking, filter to remove impurities, wash with deionized water for about 12 times until the pH value is about 6. The carbon nanofibers from which impurities have been removed are placed in a vacuum oven and dried at 65° C. for about 32 hours, and are ready for use.

[0062] (2) Surface modification of aluminum particles with composite structure

[0063] Take about 100g of aluminum particles (1-2μm) into a 500ml three-neck flask, add 150ml of absolute ethanol, stir for 15 minutes, and then ultrasonicate the liquid mixture for 30 minutes. At the same time, weigh the silane coupling agent accounting for 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com