Poly aryl ether nitrile resin, poly aryl ether nitrile fiber and preparation methods thereof

A polyarylether nitrile and resin technology applied in the field of polymer materials to achieve high thermal stability, regular molecular structure, high tensile strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides the preparation method of above-mentioned polyarylether nitrile, specifically:

[0046] (1) Polymerization reaction:

[0047] Weigh raw materials according to the following molar ratio: 2,6-dihalobenzonitrile: aromatic dihydric phenol: catalyst: aprotic strong polar solvent: dehydrating agent=1:1:1.1~1.3:14~18:6 ~8;

[0048] Under the protection of an inert gas, react the above raw materials at 140-160°C for 1-3 hours, evaporate the dehydrating agent and then raise the temperature to 190-205°C, and react for 1.5-3 hours to obtain a polyarylether nitrile solution; preferably at 200°C ;

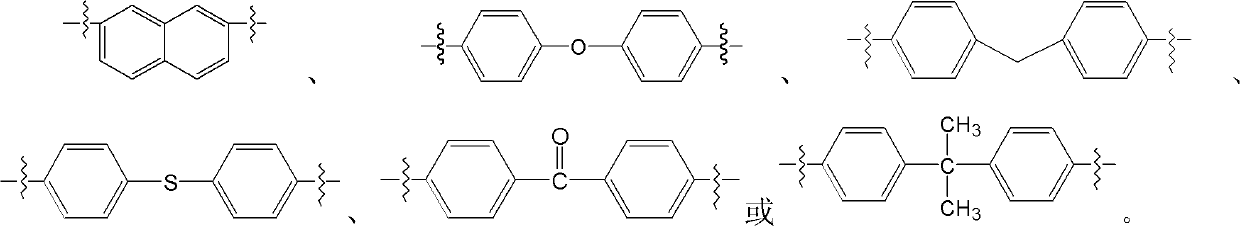

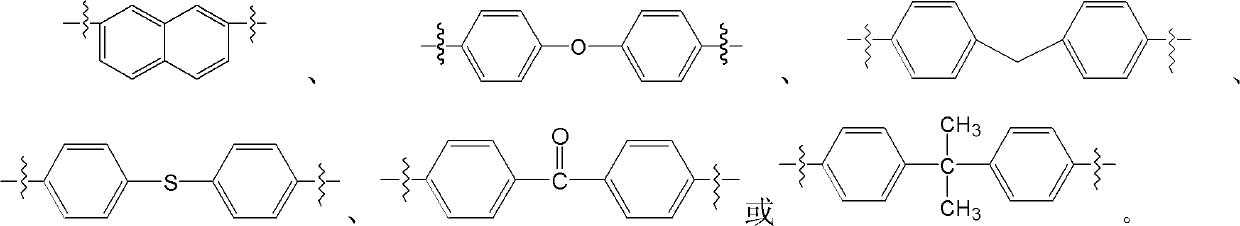

[0049] The aromatic dihydric phenol is At least one of the aromatic dihydric phenols is

[0050] (2) post-processing

[0051] The polyarylether nitrile solution is subjected to precipitation and solid-liquid separation, and the separated solid is washed, filtered and dried to obtain the polyarylether nitrile resin of the present invention. ...

Embodiment 1

[0062] The synthesis of embodiment 1 polyarylether nitrile resin, the preparation of polyarylether nitrile fiber and its properties

[0063] Add 2150 grams (12.5 moles) of 2,6-dichlorobenzonitrile, 1375 grams (12.5 moles) of hydroquinone, 2070 grams (15 moles) ) Potassium carbonate, 20L sulfolane and 9L toluene, slowly pass through argon protection, start stirring, raise the temperature to 160°C for dehydration reaction for 1.5 hours, distill the toluene through the water separator, raise the temperature to 200°C for 2 hours to stop the reaction. The reactant is put into 60L of methanol, heated, stirred and refluxed for 3 hours and separated from the solid and liquid by the centrifuge. The liquid is transported to the rectifying tower for rectification and recovery of the solvent for recycling. pH value is 4-6), then washed with boiling water, filtered, repeated 5 times, and dried at 150° C. for 8 hours to obtain 2745 grams of polyarylether nitrile resin.

[0064] The number ...

Embodiment 2

[0066] The synthesis of embodiment 2 polyarylether nitrile resin, the preparation and performance of polyarylether nitrile fiber

[0067] Add 2150 grams (12.5 moles) of 2,6-dichlorobenzonitrile, 1100 grams (10 moles) of hydroquinone, 465 grams (2.5 moles) ) 4,4-diphenol, 2070 grams (15 moles) of potassium carbonate, 20L sulfolane and 9L toluene, slowly pass into argon protection, start stirring, heat up to 160 ° C for 2 hours of dehydration reaction, and steam out through the water separator Toluene, raise the temperature to 200°C for 1.5 hours to stop the reaction. The reactant is put into 60L of methanol, heated, stirred and refluxed for 3 hours and separated from the solid and liquid by the centrifuge. The liquid is transported to the rectifying tower for rectification and recovery of the solvent for recycling. pH value is 4-6), then washed with boiling water, filtered, repeated 5 times, and then dried at 150 ° C for 8 hours to obtain 2745 grams of polyarylether nitrile re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com