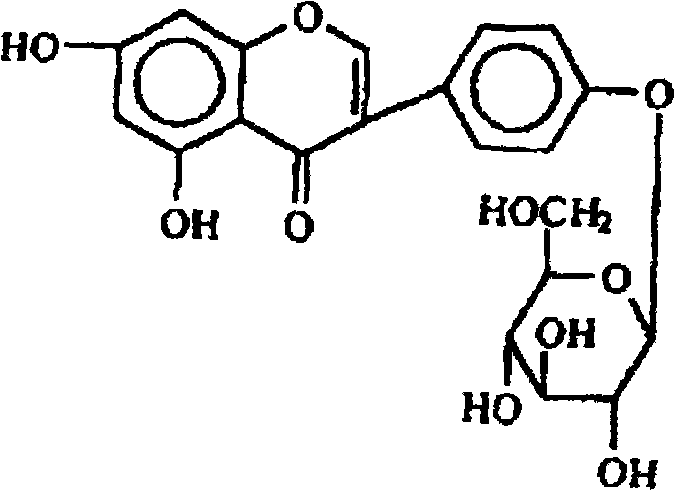

Method for extracting sophoricoside from sophora fruits

A technology of sophorin and sophora, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of low product content, large amount of toxic organic solvents, etc., and achieve large preparation volume and easy operation Simple, good leaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Pulverize the medicinal material Sophora japonica, weigh 1kg, add 10L of pH 9.0 alkaline dilute alcohol solution (20% ethanol) containing 20g of borax, heat and reflux for extraction twice, each time for 2.5 hours, combine the extracts, add hydrochloric acid to adjust to medium Then add the extract to the AB-8 macroporous resin column for adsorption, wash with water until the sugar reaction is negative, then elute with 5BV of 65% ethanol, the elution flow rate is 0.5BV / h, collect the eluate, Concentrate to extract, add 120ml of ethyl acetate to dissolve, filter, then dissolve the insoluble matter with 100ml of acetone, filter, and dissolve the filter cake with 70% ethanol for 3 times to obtain 37.1g of sophorin, with a content of 98.3%.

Embodiment 2

[0022] Pulverize the medicinal material Sophora japonica, weigh 1kg, add 8L of pH 9.0 alkaline dilute alcohol solution (15% ethanol) containing 18g of borax, heat and reflux for extraction 3 times, each time for 2 hours, combine the extracts, add hydrochloric acid to adjust to medium Then add the extract to the HPD450 macroporous resin column for adsorption, wash with water until the sugar reaction is negative, then elute with 6BV of 70% ethanol, the elution flow rate is 2BV / h, collect the eluate, concentrate to Ointment, add 100ml ethyl acetate to dissolve, filter, insoluble matter is dissolved with 80ml of acetone again, filter, and filter cake dissolves and crystallizes with 80% ethanol 4 times to obtain sophorin 33.6g, content 98.7%.

Embodiment 3

[0024] Pulverize the medicinal material Sophora japonica, weigh 2kg, add 22L of pH 8.5 alkaline dilute alcohol solution (25% ethanol) containing 28g of borax, heat and reflux to extract 3 times, each time for 3 hours, combine the extracts, add hydrochloric acid to adjust to medium Then add the extract to the HPD450 type macroporous resin column for adsorption, first wash with water until the sugar reaction is negative, then elute with 4BV of 50% ethanol, the elution flow rate is 1.5BV / h, collect the eluate, and concentrate to Extract, add 250ml ethyl acetate to dissolve, filter, dissolve insoluble matter with 180ml of acetone, filter, and dissolve the filter cake with 70% ethanol to crystallize twice to obtain 70.3g of sophorin, content 97.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com