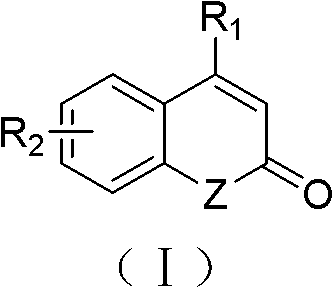

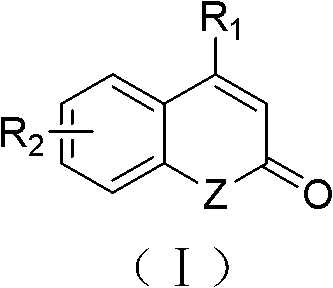

Solid-phase synthesis method of coumarin and analogue thereof

A technology for solid-phase synthesis and analogs, applied in the direction of organic chemistry, etc., can solve the problems of low yield and the like, and achieve the effects of good product yield, simple post-processing, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

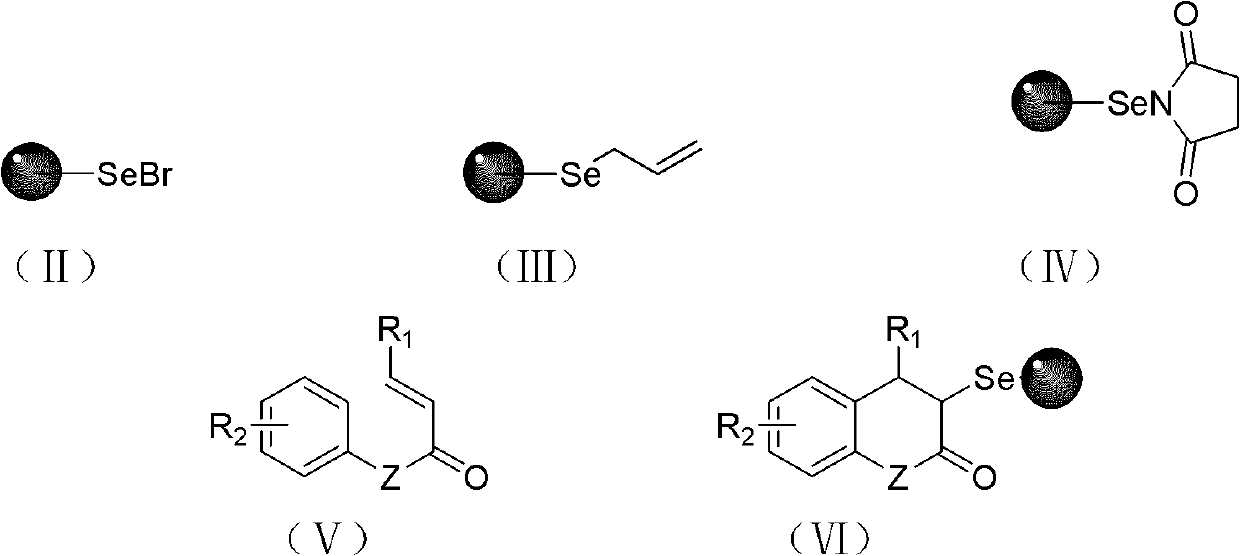

Embodiment 1

[0037] Example 1 Under nitrogen protection, 1% cross-linked polystyrene supported selenium bromide (II) (Br% = 0.99mmol / g) (2.5g, 2.48mmol), tetrahydrofuran (24mL) and N,N-di Methylformamide (6 mL) was placed in a reaction flask and allowed to stand at room temperature for 4 h. After the resin was swollen, sodium borohydride (189.2mg, 5.0mmol) was added, and the reaction was stirred at 40°C for 8h. Allyl bromide (0.665g, 5.5mmol) was added dropwise, and the reaction was continued to stir at 40°C for 12h. After the reaction is complete, filter with a sand core funnel, and then use dichloromethane (3×10mL), water (3×10mL), water+tetrahydrofuran (V / V=1:1, 3×10mL), tetrahydrofuran (3×10mL) , ethanol (3×10mL), methanol (3×10mL), ether (3×10mL), dichloromethane (10mL), acetone (3×10mL) to wash the resin, and dry to obtain polystyrene-loaded allyl selenide (III) (2.36 g, 98.2%).

[0038] IR(KBr): υ max =3068, 3019, 2847, 1565, 1415, 1185, 1016, 907, 751cm -1 .

Embodiment 3

[0040] Example 3 Under nitrogen protection, 1% cross-linked polystyrene supported selenium bromide (II) (Br% = 0.99mmol / g) (2.5g, 2.48mmol), tetrahydrofuran (80mL) and N, N-di Methylformamide (20 mL) was placed in a reaction flask and allowed to stand at room temperature for 4 h. After the resin was swollen, sodium borohydride (0.946g, 25.0mmol) was added, stirred at 40°C for 12h, allyl bromide (3.08g, 25.5mmol) was added dropwise, and stirred at 40°C for 24h. After the reaction is completed, filter with a sand core funnel, and then use dichloromethane (5×10mL), water (3×10mL), water+tetrahydrofuran (V / V=1:1, 3×10mL), tetrahydrofuran (3×10mL) , ethanol (3×10mL), methanol (3×10mL), ether (3×10mL), dichloromethane (10mL), acetone (3×10mL) to wash the resin, and dry to obtain polystyrene-loaded allyl selenide (III) (2.35 g, 98.0%), IR is consistent with Example 1.

Embodiment 4

[0041] Example 4 Under nitrogen protection, 1% cross-linked polystyrene supported selenium bromide (II) (Br% = 0.99mmol / g) (2.5g, 2.48mmol), tetrahydrofuran (24mL) and absolute ethanol (6mL ) in a reaction flask and let it stand at room temperature for 4h. After the resin was swollen, sodium borohydride (189.2mg, 5.0mmol) was added, stirred at 60°C for 2h, allyl bromide (0.665g, 5.5mmol) was added dropwise, and stirred at 40°C for 10h. After the reaction is complete, filter with a sand core funnel, and then use dichloromethane (3×10mL), water (3×10mL), water+tetrahydrofuran (V / V=1:1, 3×10mL), tetrahydrofuran (3×10mL) , ethanol (3×10mL), methanol (3×10mL), ether (3×10mL), dichloromethane (10mL), acetone (3×10mL) to wash the resin, and dry to obtain polystyrene-loaded allyl selenide (III) (2.30 g, 96.0%), IR is consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com