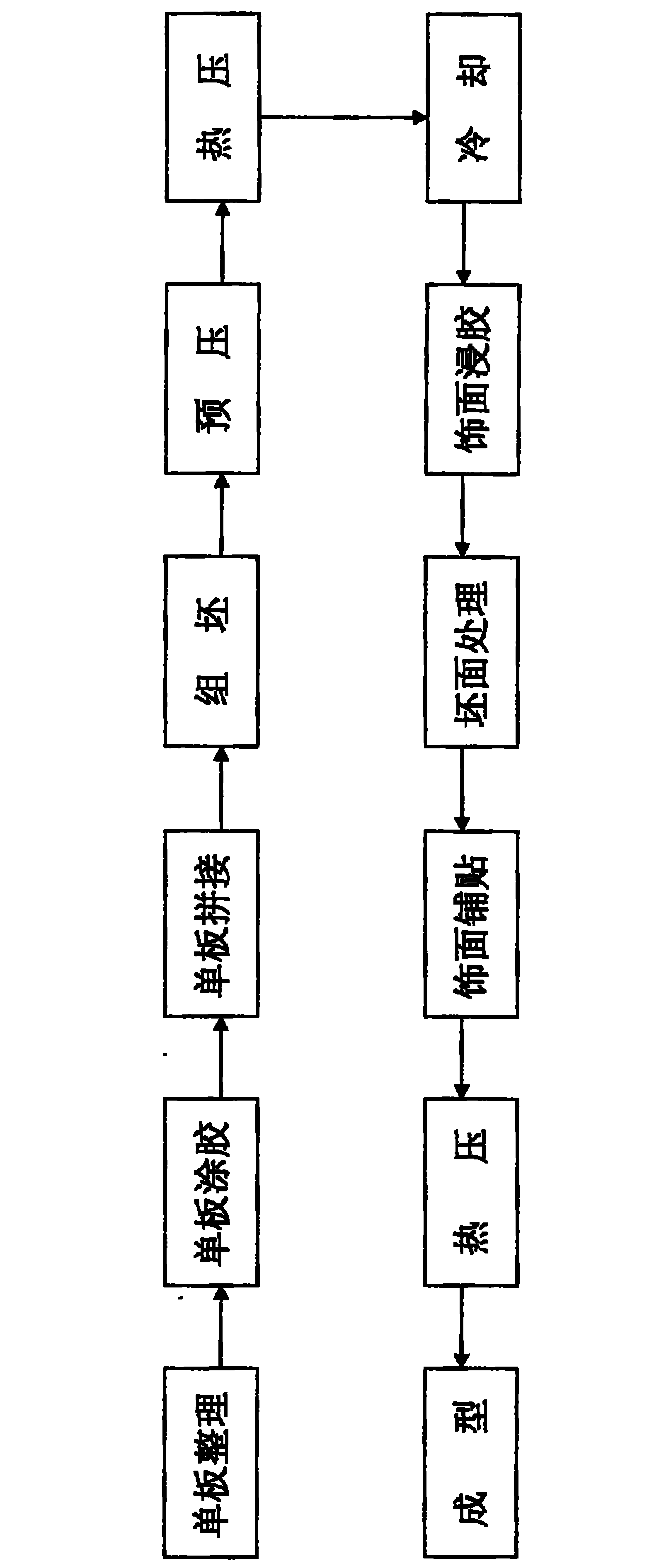

Production method and manufacturing process for environmentally-friendly decorative board

A manufacturing process and technology for decorative panels, applied in the field of production of environmentally friendly decorative panels, can solve the problems of non-waterproof, moisture-proof, fireproof, low service life of hardware, excessive formaldehyde emission, etc., to reduce pollution, prolong service life, and achieve uniform quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: make 2400*1200*10mm, environmental protection decorative board.

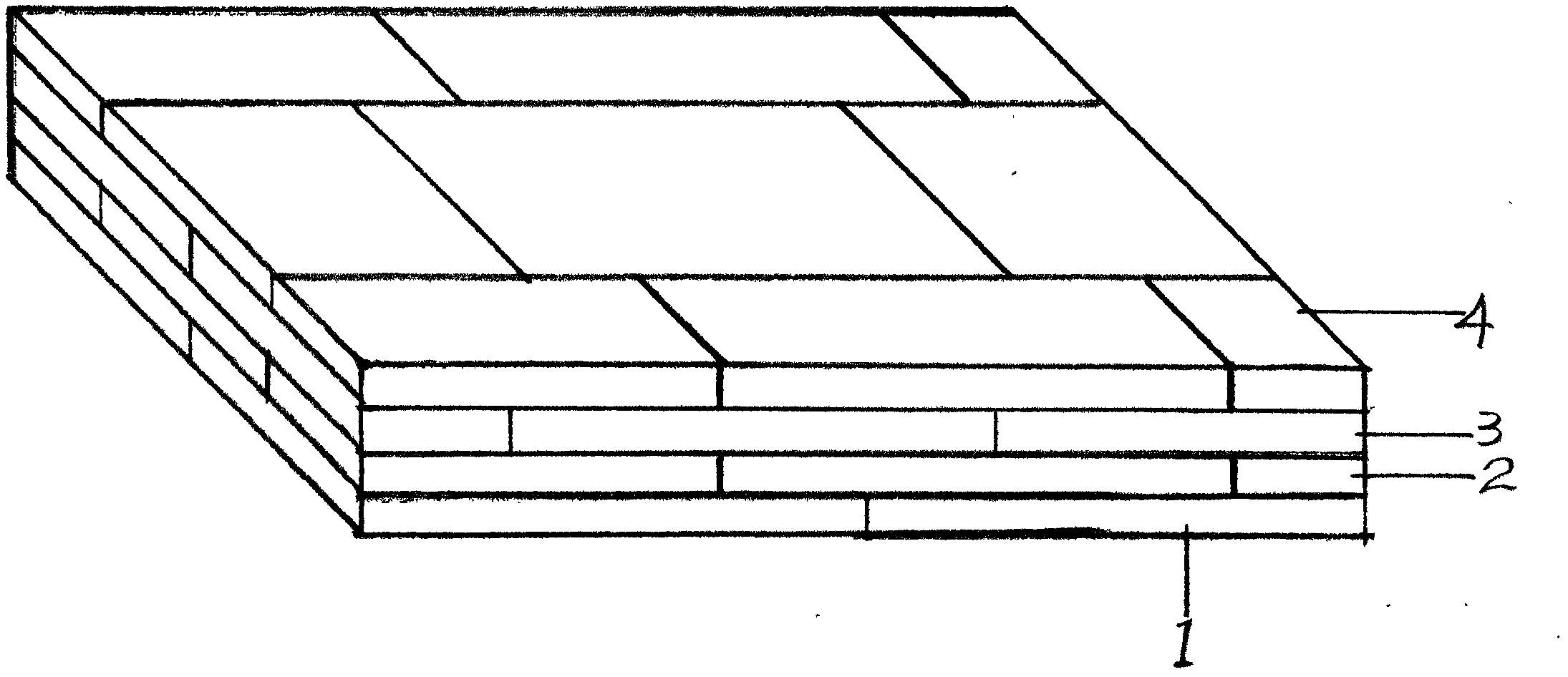

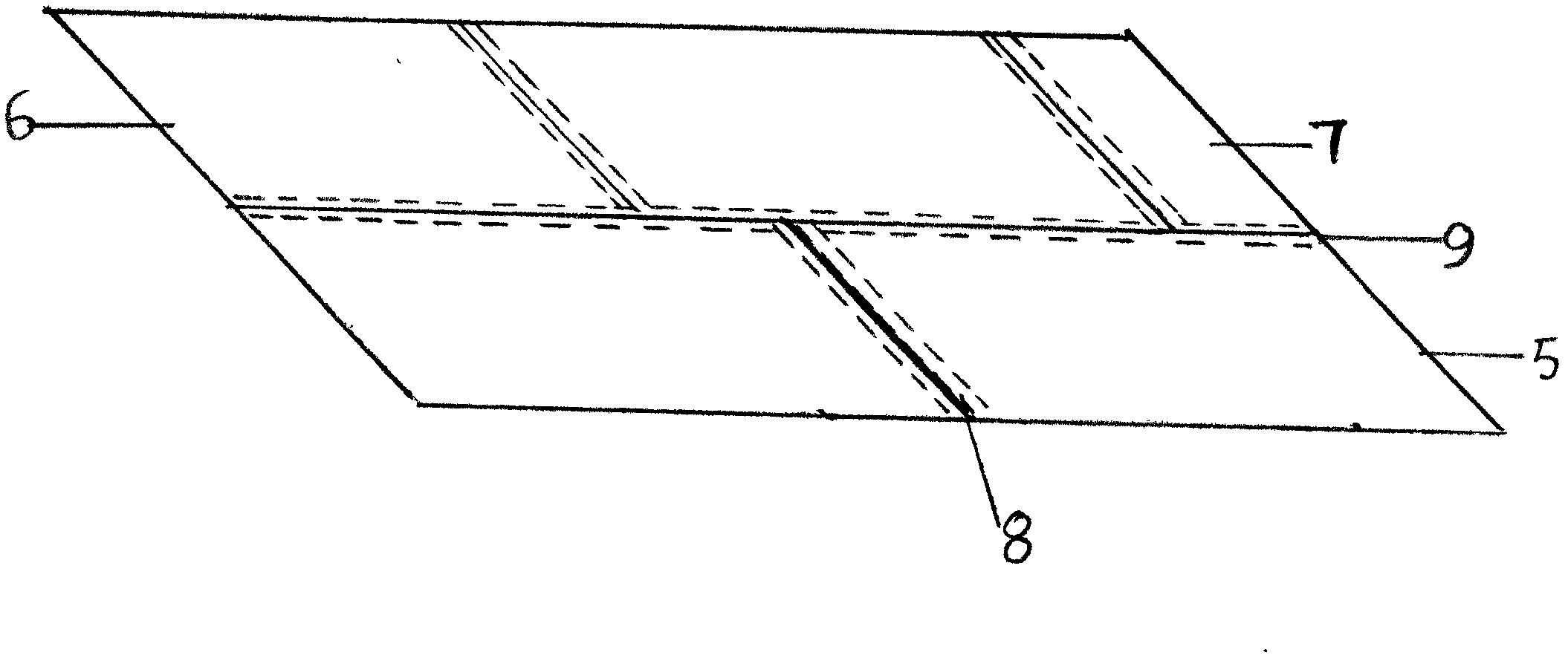

[0020] 1. Parameters in the material preparation stage: (1) The moisture content of the fast-growing poplar rotary cut veneer is below 7%, the size is 615*1220*2.5mm, and the density is 0.31g / cm 3 . (2) Refer to the density of red pine: 0.40-0.50g / cm 3 , the density of the finished environmentally friendly decorative board is 0.45g / cm 3 . (3) Determining the compression ratio: the density of the finished environmentally friendly decorative board ÷ the density of the fast-growing poplar rotary-cut veneer = 0.45 ÷ 0.30 = 1.5, and the thickness of the billet is established to be 15mm. For the form of veneer assembly, see the attachment figure 2 , 3 , 4, 5, 6. (4) Determine the amount of sizing: by m 2 165-200g.

[0021] 2. Determine the process parameters during pressing. (1) The curing temperature of the modified urea-formaldehyde resin and melamine blend is 125°C, the time is 5-8min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com