Machining method for complex surface of fluid dynamic pressure and static pressure combined mechanical seal ring for nuclear main pump

A technology of mechanical seals and complex shapes, applied in metal processing equipment, manufacturing tools, bonded grinding wheels, etc., can solve the problems of difficult to obtain surface shape accuracy, poor shape retention, and difficulty in accurate shape modification, and achieve low cost, The effect of stable processing state and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

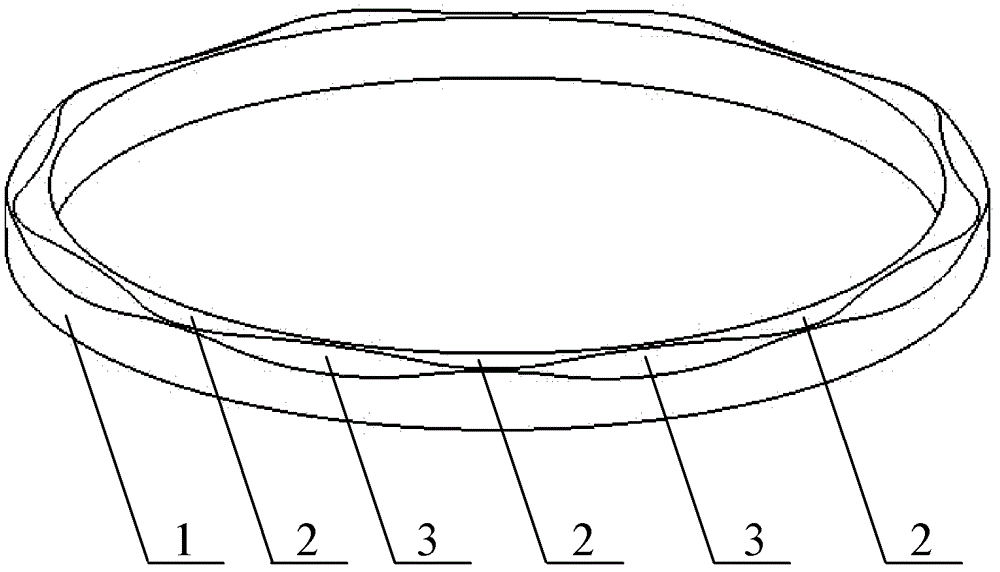

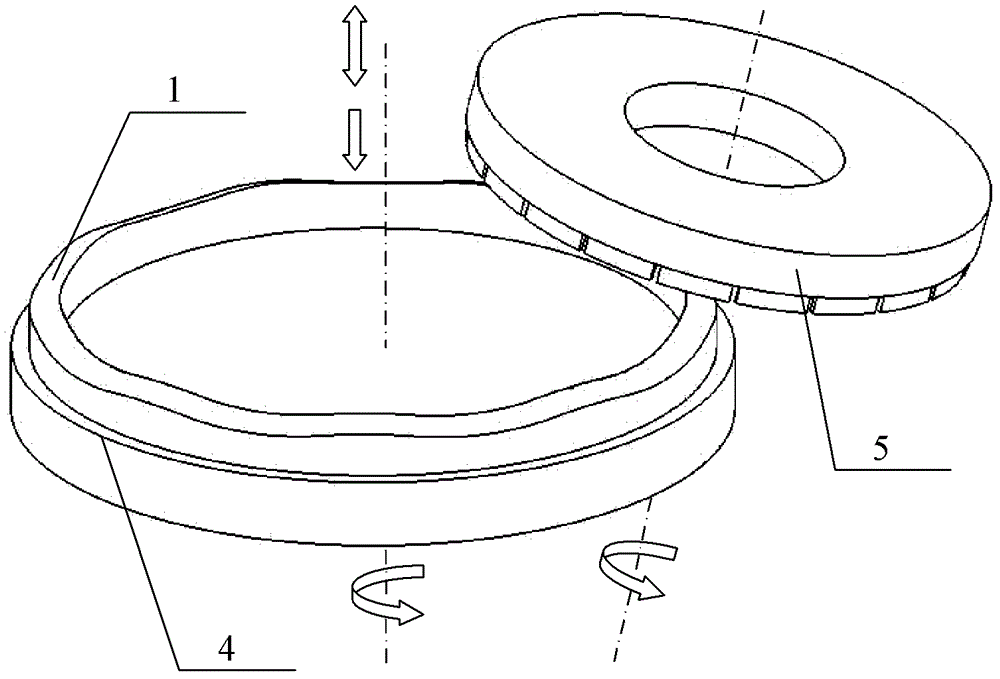

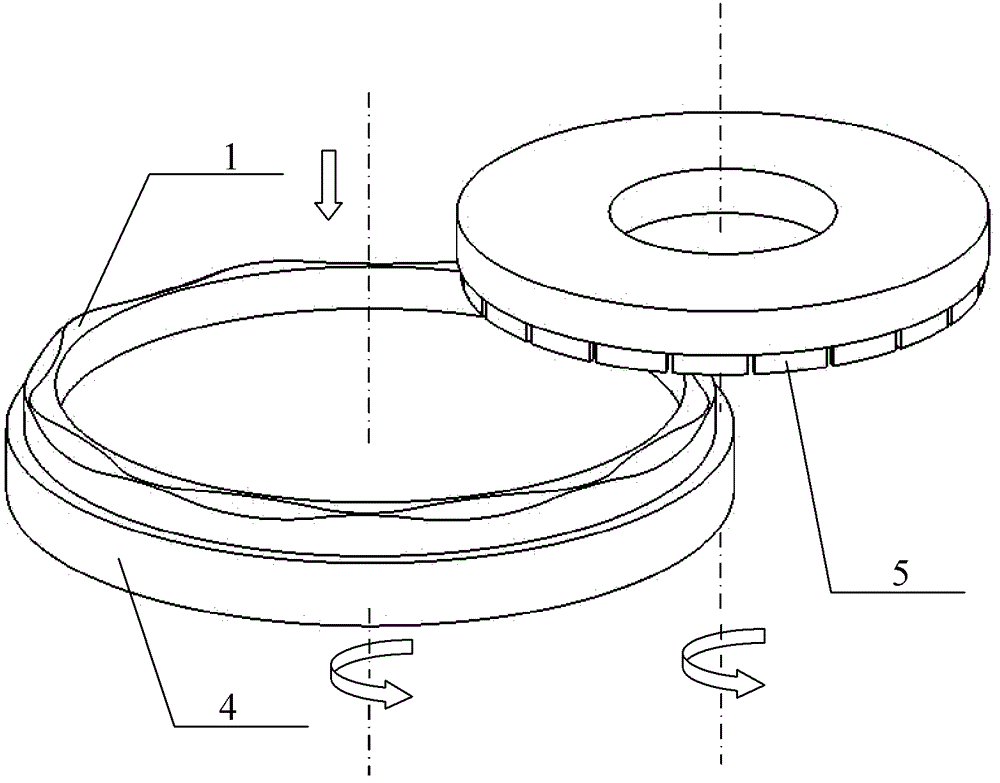

[0017] as attached figure 1 As shown, the hydrodynamic and static pressure combined mechanical seal ring for the nuclear main pump to be processed has an outer diameter of 304 mm and an inner diameter of 277 mm. The inclination angle of the radial profile of the inclined corrugated surface is equal everywhere, and the radial profile inclination angle is 0.001 radians. The intersection curve between the dam surface and the equi-inclined corrugated surface is a closed wave line extending along the circumferential direction with a wave number of 9. The material is tungsten carbide. Clamp the inner peripheral surface, outer peripheral surface and the other end surface of the processed sealing ring in the center of the ultra-precision rotary table supported by the air bearing. The rotary table can drive the seal around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com