A field coring device and method for rock true triaxial test

A coring device and true three-axis technology, applied in the field of rock equipment, can solve the problems of reducing construction line, increasing energy release rate, economic property loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

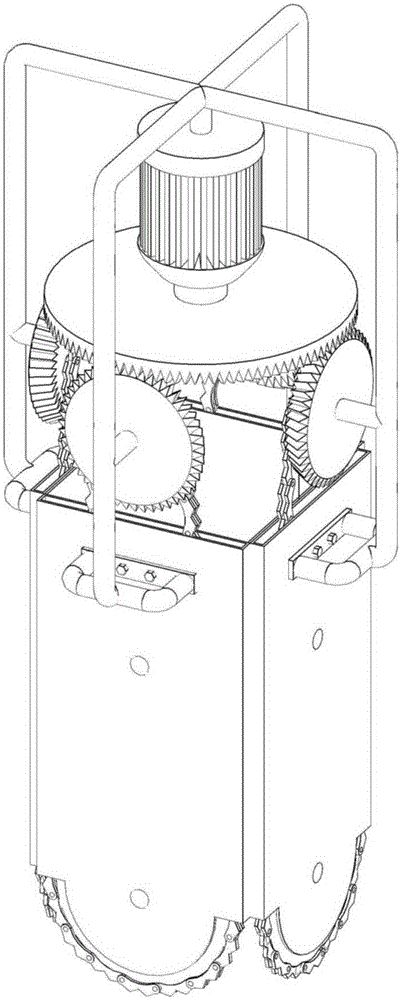

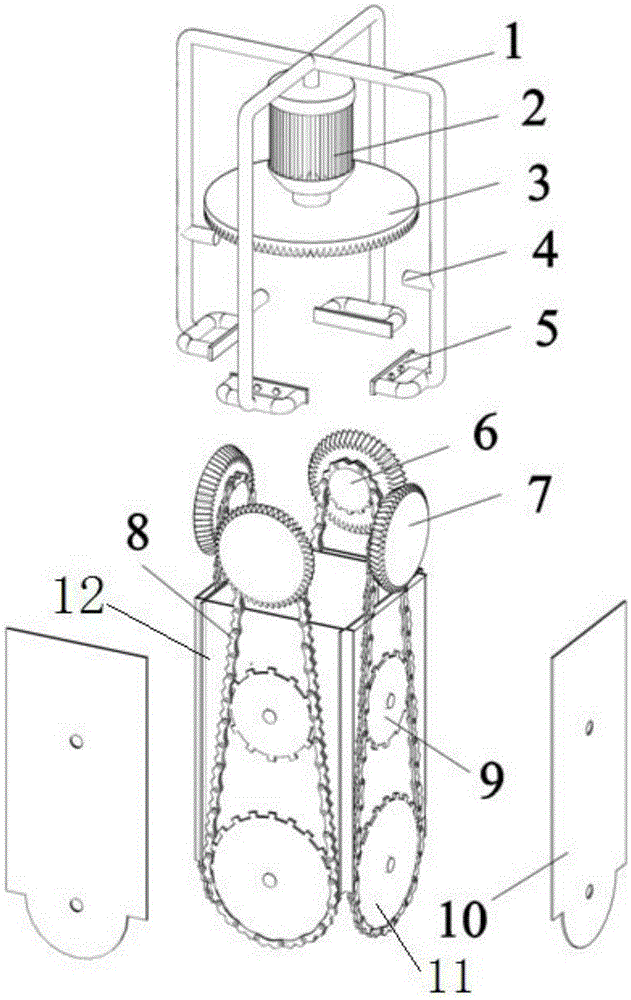

[0029] Embodiment 1: a kind of on-the-spot coring device for rock true triaxial test, its structure is as Figure 1-3 Shown: including fixed frame 1, cutting cylinder wall 10, coring cylinder 12, power system and chain type cutting system, power system is set on the fixed frame 1, chain type cutting system is set on the core tube 12, fixed frame 1 The bottom end is connected with the cutting cylinder wall 10 and then placed on the core cylinder 12. The power system transmits the power to the chain cutting system to realize the cutting of the rock by the chain cutting system.

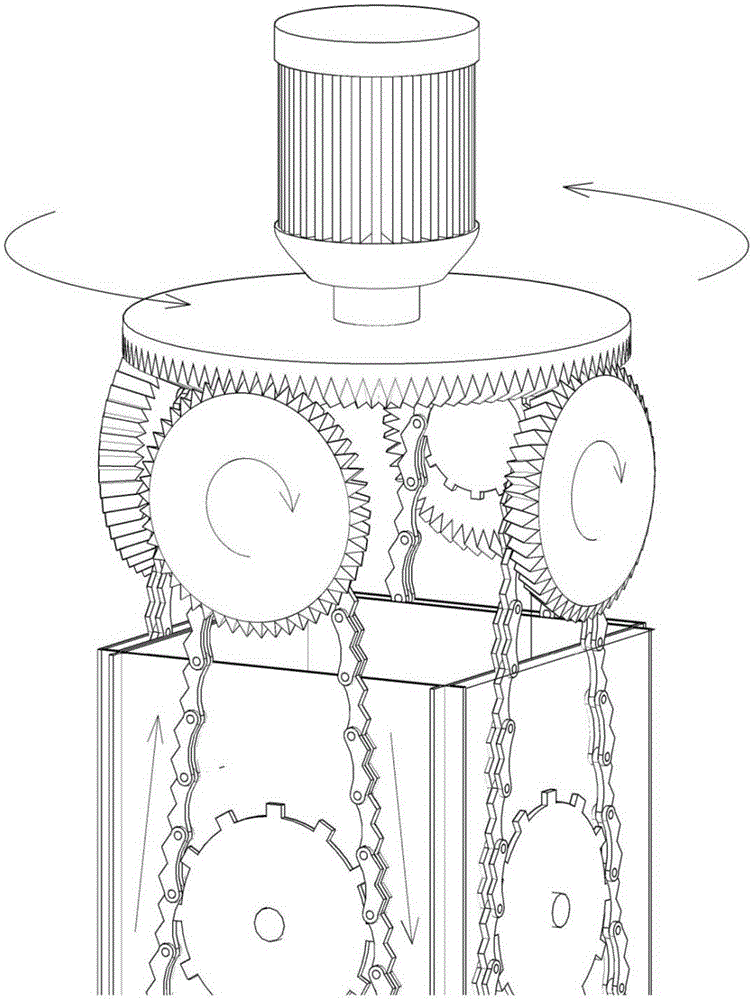

[0030] The power system includes an engine 2 arranged on the top of the fixed frame 1, the engine shaft is connected with the disc gear 3, the disc gear 3 meshes with the orthogonal gear 7 on the orthogonal gear shaft 4, and the orthogonal gear shaft 4 Located in the middle of the fixed frame 1; the disc gear 3 is also fixedly connected with the driving chain gear 6.

[0031] The orthogonal gears 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com