Cutting device for semicircular notch of pipe body

A cutting device and semi-circular technology, applied in the direction of tubular objects, gas flame welding equipment, chucks, etc., can solve the problems of large drag, impenetrable cutting, and uneven edges of the cutting seam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

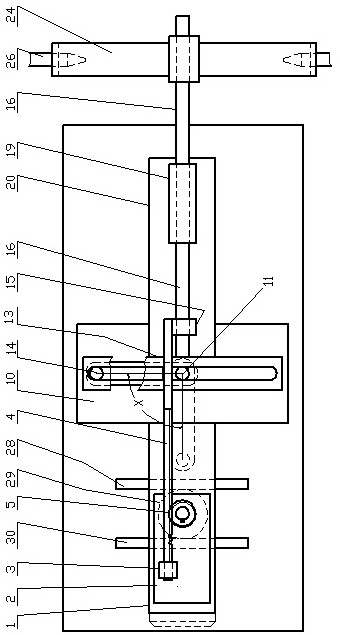

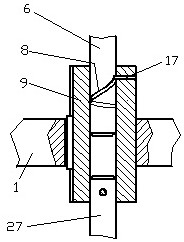

[0014] A cutting device for a semicircular notch of a pipe body, which is symmetrically provided with two cutting torches 26 outside the pipe body 23, the pipe body is clamped by a chuck 22, and the chuck and the horizontal output shaft 12 of the reducer 10 Connection, the vertical output shaft 11 of the speed reducer is fixedly connected with the center shaft of the crank throw 14, and the eccentric shaft of the crank throw is inserted in the strip groove of the strip plate 13, and the length of the strip groove is equal to the length of the vertical output shaft and the crank throw. The distance between the eccentric shafts (that is, the radius of the pipe notch) is 2.2 times. The middle part of one side of the strip plate is fixedly connected with the left end of the cross bar 16. The middle part of the cross bar 16 is inserted in the guide sleeve 19. The axis of the guide sleeve Parallel to the axis of the pipe body, the guide sleeve is connected to the guide sleeve bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com