Bimetal vacuum diffusion welding method of hydraulic pump/motor cylinder body

A vacuum diffusion, hydraulic motor technology, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of hydraulic pump/motor cylinder block wear resistance, specific gravity segregation, short service life, etc., to eliminate casting stress And the effect of microscopic defects, dense structure and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

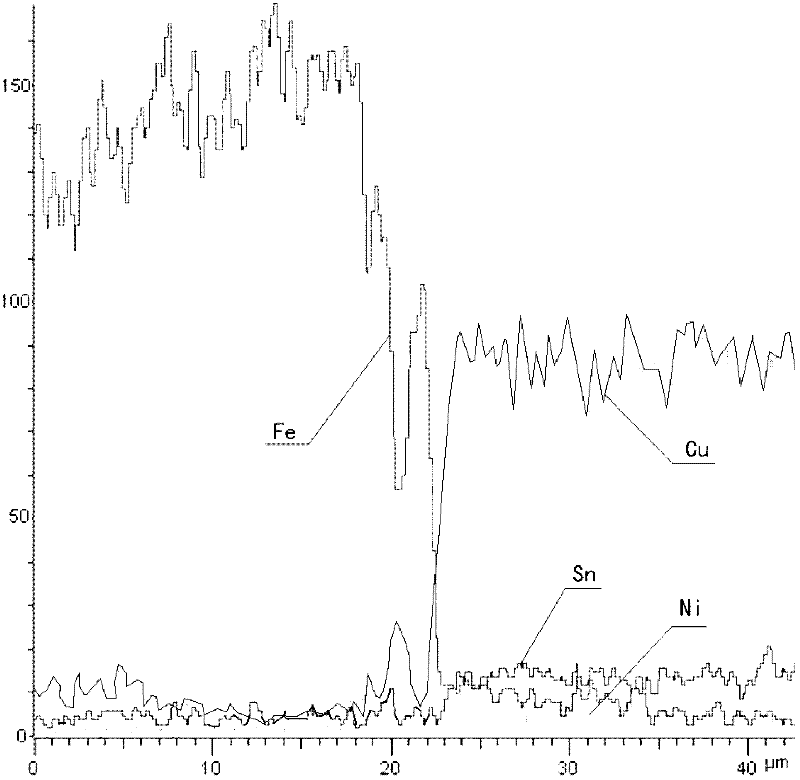

Examples

Embodiment 1

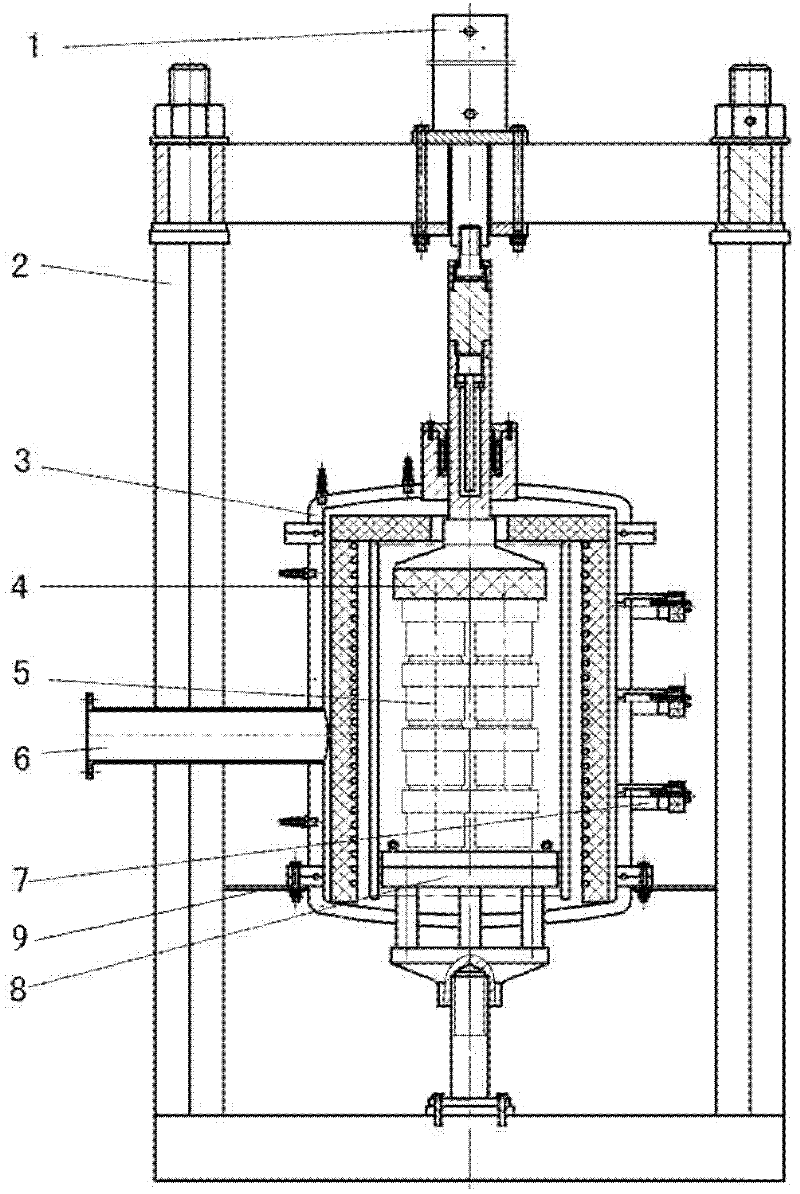

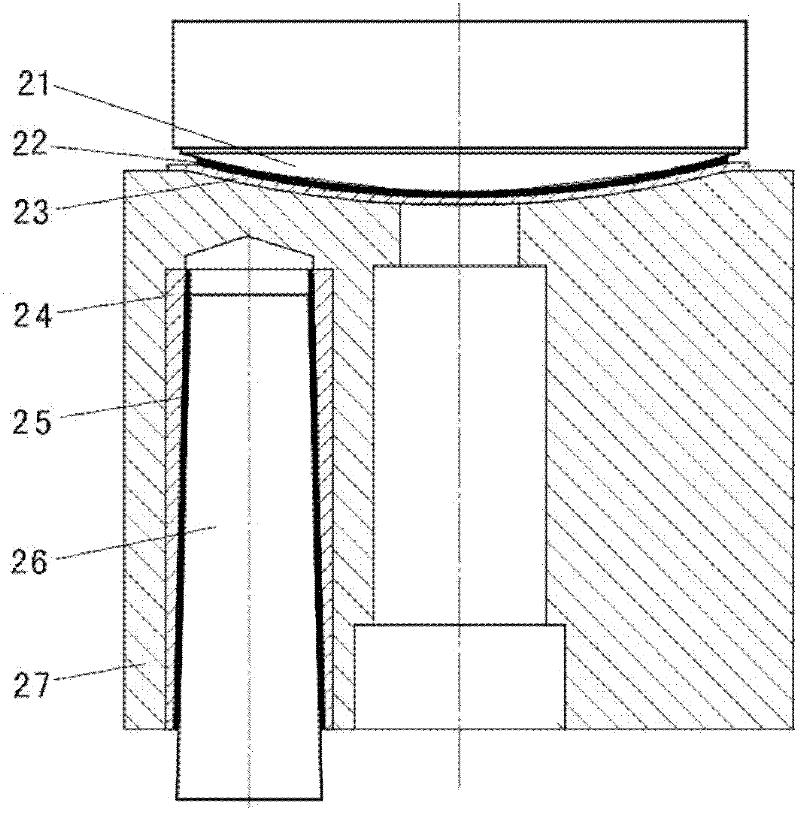

[0033] Step 1. First make each component according to the drawing specifications, including the base body 27 of the workpiece cylinder, the copper alloy sleeve 24 to be welded, the hemispherical copper alloy plate 23, and the plunger hole expansion core 26 and hemispherical core used in conjunction with the welding process. The surface indenter 21 and the copper alloy sleeve 24 are processed into a structure with a cylindrical outer diameter and a conical inner diameter. The outer circular shape of the plunger hole 26 is matched with the inner hole shape of the copper alloy sleeve 24 to control the size according to the gap. The hemispherical surface pressure The spherical curvature of the head 21 is consistent with the hemispherical copper alloy plate 23;

[0034] then follow figure 2The structure shown in the figure is assembled, that is, a corresponding copper alloy sleeve 24 is pressed into each plunger hole of the base body 27, the tapered opening of the copper alloy sle...

Embodiment 2

[0042] Step 1, implement according to the step of embodiment 1;

[0043] Step 2. Place 3 cylinder components 5 on each layer, and place 3 layers in total; in order to prevent welding between layers, asbestos cloth with a thickness of 2.5 mm must be laid between layers for isolation;

[0044] Step 3. Always control the vacuum degree in the vacuum hot pressing furnace to be 1×10 -2 Pa, and control the temperature rise and pressurization process in the vacuum hot-press furnace according to the following three stages:

[0045] 3.1) within 120 minutes, the temperature in the vacuum hot-pressing furnace is evenly raised from room temperature to 600°C, and at the same time, the downward pressure of the lower pressure head 4 in the vacuum hot-pressing furnace reaches 8 MPa, and the temperature is kept for 15 minutes;

[0046] 3.2) within 80 minutes, the temperature in the vacuum hot-pressing furnace is uniformly raised from 600°C to 750°C, and at the same time, the downward pressure ...

Embodiment 3

[0050] Step 1, implement according to the step of embodiment 1;

[0051] Step 2. Place 7 cylinder components 5 on each layer, and place 3 layers in total; in order to prevent welding between layers, asbestos cloth with a thickness of 2.2mm must be paved between layers for isolation;

[0052] Step 3, sintering: Use the control system to set the corresponding vacuum welding parameters, and always control the vacuum degree in the vacuum hot pressing furnace to 1×10 -1 Pa, and control the temperature rise and pressurization process in the vacuum hot-press furnace according to the following three stages:

[0053] 3.1) within 100 minutes, the temperature in the vacuum hot-pressing furnace is evenly raised from room temperature to 600°C, and at the same time, the downward pressure of the lower pressure head 4 in the vacuum hot-pressing furnace reaches 6 MPa, and the temperature is kept for 12 minutes;

[0054] 3.2) within 70 minutes, the temperature in the vacuum hot-pressing furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com