Supercooled IN718 high-temperature alloy purifying agent and preparation method for same

A technology of IN718 and superalloy, which is applied in the field of purifying agent and its preparation, can solve the problems such as the inability to carry out research on the microstructure evolution of IN718 superalloy, the difficulty of obtaining a large degree of supercooling, and the inability to meet the requirements of deep supercooling and rapid directional solidification. Granular refinement effect, low price, and the effect of less harmful gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Composite molten salt purifier composition (percentage): 50% calcium fluoride (CaF 2 ), 9% sodium chloride (NaCl), 9% potassium chloride (KCl), 22% calcium oxide (CaO), 4.5% titanium oxide (TiO 2 ), 4.5% magnesium oxide (MgO), 0.5% aluminum fluoride (AlF 3 ), the rare earth compound is LaCl 3 , The amount of rare earth added is 0.5%.

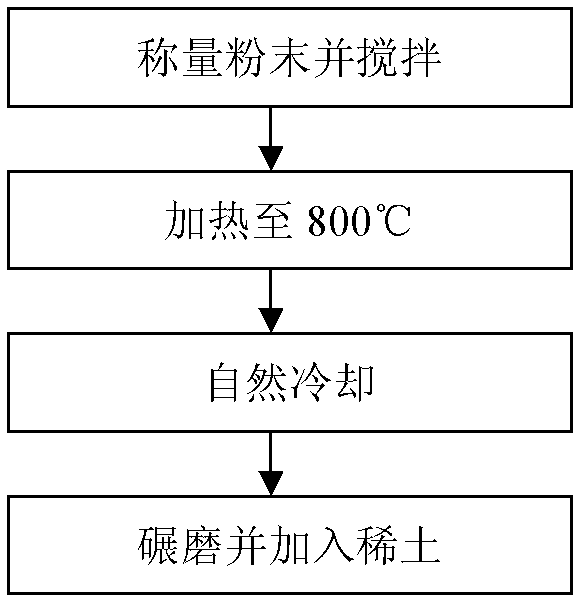

[0029] The production method of the high-temperature alloy purifying agent is as follows: according to the above ratio, the weighed calcium fluoride, sodium chloride, potassium chloride, calcium oxide, magnesium oxide, aluminum fluoride and titanium oxide are fully stirred in a mortar, Then add the mixed powder into the corundum crucible, put the crucible into the heat treatment furnace and heat it. After the temperature of the furnace rises to 800°C, keep it warm for 8 hours. , crush it and put it into a ball mill to grind it into powder. After sieving, add a rare earth compound and mix it with a ball mill. The prepared purifying agen...

Embodiment 2

[0032] Composite molten salt purifier composition (percentage): 55% calcium fluoride (CaF 2 ), 8% sodium chloride (NaCl), 8% potassium chloride (KCl), 18% calcium oxide (CaO), 5.5% titanium oxide (TiO 2 ), 4% magnesium oxide (MgO), 0.75% aluminum fluoride (AlF 3 ), the rare earth compound is LaCl 3 , The amount of rare earth added is 0.75%.

[0033] The production method of the high-temperature alloy purifying agent is as follows: according to the above ratio, the weighed calcium fluoride, sodium chloride, potassium chloride, calcium oxide, magnesium oxide, aluminum fluoride and titanium oxide are fully stirred in a mortar, Then add the mixed powder into the corundum crucible, put the crucible into the heat treatment furnace and heat it. After the temperature of the furnace rises to 800°C, keep it warm for 8 hours. , crush it and put it into a ball mill to grind it into powder. After sieving, add a rare earth compound and mix it with a ball mill. The prepared purifying agen...

Embodiment 3

[0036] Composite molten salt purifier composition (percentage): 45% calcium fluoride (CaF 2 ), 12% sodium chloride (NaCl), 12% potassium chloride (KCl), 19% calcium oxide (CaO), 4% titanium oxide (TiO 2 ), 6% magnesium oxide (MgO), 1% aluminum fluoride (AlF 3 ), the rare earth compound is LaCl 3 , The amount of rare earth added is 1%.

[0037] The production method of the high-temperature alloy purifying agent is as follows: according to the above ratio, the weighed calcium fluoride, sodium chloride, potassium chloride, calcium oxide, magnesium oxide, aluminum fluoride and titanium oxide are fully stirred in a mortar, Then add the mixed powder into the corundum crucible, put the crucible into the heat treatment furnace and heat it. After the temperature of the furnace rises to 800°C, keep it warm for 8 hours. , crush it and put it into a ball mill to grind it into powder. After sieving, add a rare earth compound and mix it with a ball mill. The prepared purifying agent is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com