Quartz high temperature melting lump waterpower spurting breaking device

A crushing device, high temperature technology, applied in grain processing and other directions, can solve the problems of high labor intensity, waste of non-renewable quartz ore sources, poor labor hygiene conditions, etc., and achieve the effect of improving product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

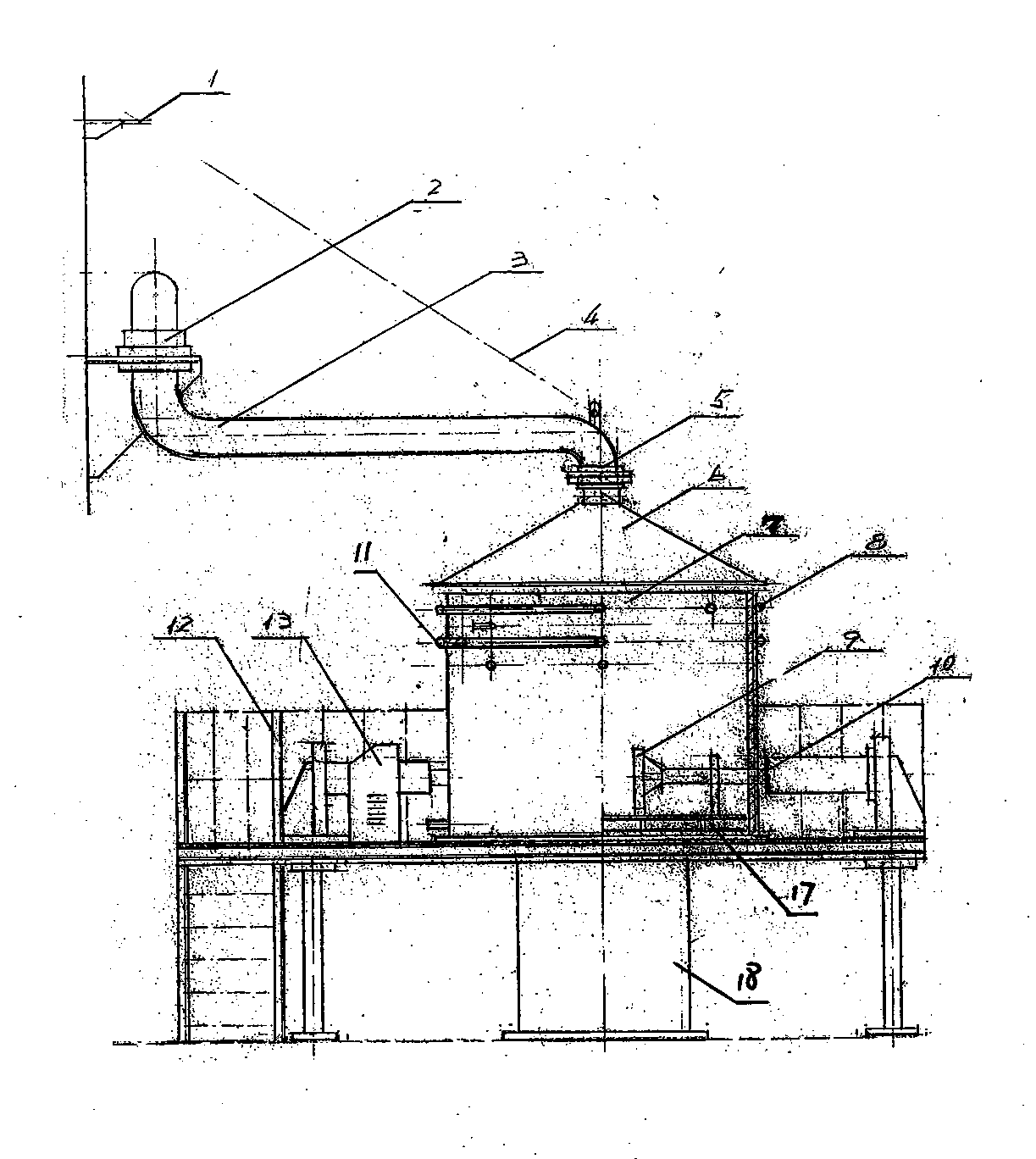

[0013] A quartz high-temperature fused lump hydraulic sputtering crushing device is provided with an anti-corrosion cylinder 7 mounted on a frame, the bottom of the cylinder 7 is provided with a water-cooled bottom plate 17, and the top of the cylinder 7 is provided with a gas collecting hood 6. A pair of extrusion heads 9 are arranged above the bottom plate 17, and the extrusion heads 9 can move radially along the high-temperature molten mass. Self-cooling system 8 and high-temperature molten lump water-inlet sputtering system 11. A support cylinder 18 is set under the cylinder body 7, and the entire hydraulic sputtering system is installed on a steel frame platform with a metal guardrail 12, and a process console 13 is also arranged on the platform.

[0014] The top of the gas collecting hood 6 is connected to the exhaust pipe 3 through the flange 5 , and the exhaust pipe 3 is connected to the frame through the rotary device 2 . The displacement of the gas collecting hood 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com