Compensatory turning method for three-high stand

A rack and turning technology, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of low processing efficiency, chipping waste, reducing the online use time of the rack, etc., and achieve the effect of improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

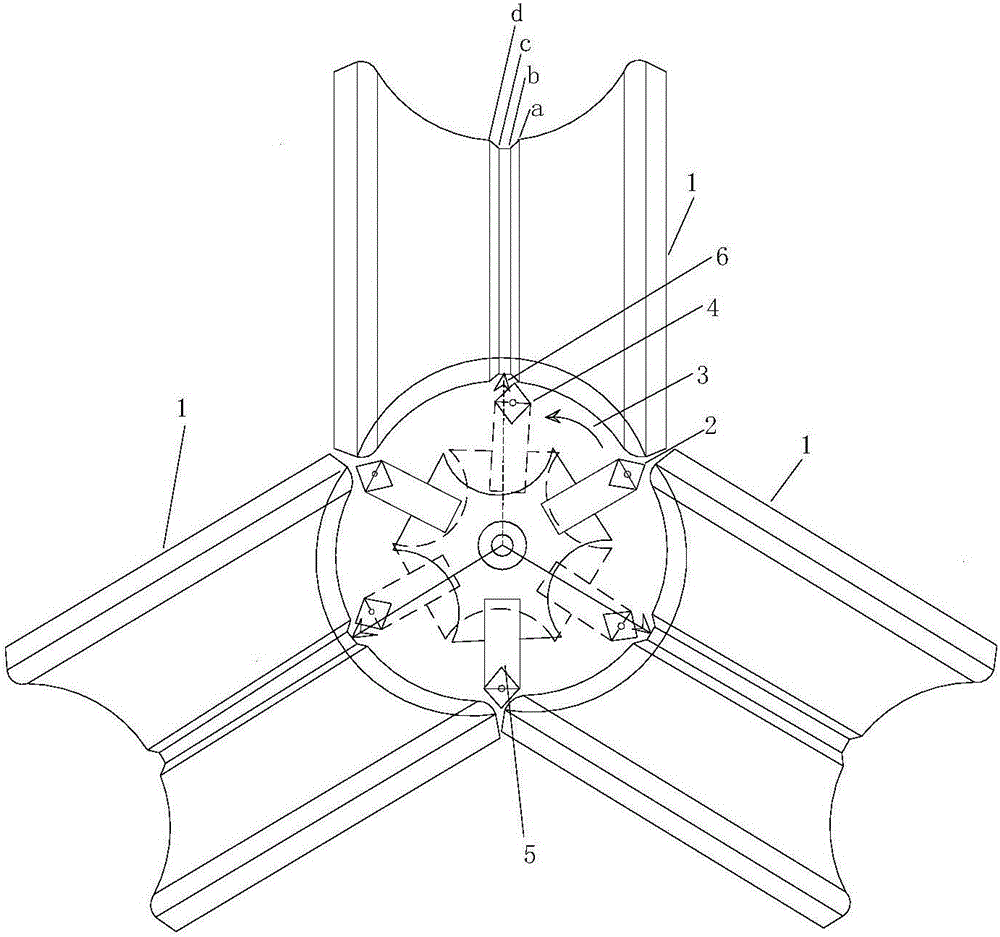

[0020] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0021] In order to overcome the limitation of the existing three-roller frame turning process by the fixed program of the imported machine tool, the three roll rings must be rounded by multi-cutting and then measured with a three-jaw inner diameter micrometer to be compensated. The processing efficiency is low, the blade wears quickly and Severe passivation can easily cause chipping and waste products, increase the surface roughness of the rolls, and even stick to the surface of the roll ring when rolling steel on the line, which causes the quality of the steel pipe to be degraded, reduces the service life of the rack, and consumes a large cost and waste of tools and roll rings. serious. The invention provides a three-roller frame proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com