Shiitake mushroom culture medium and preparation method thereof

A shiitake mushroom medium and culture medium technology, applied in botany equipment and methods, mushroom cultivation, cultivation, etc., can solve the problems of low nutrient content, reduced production of fungus, easy aging of mycelium, etc., and achieve rich nutrients and economic benefits Visible, simple raw material source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

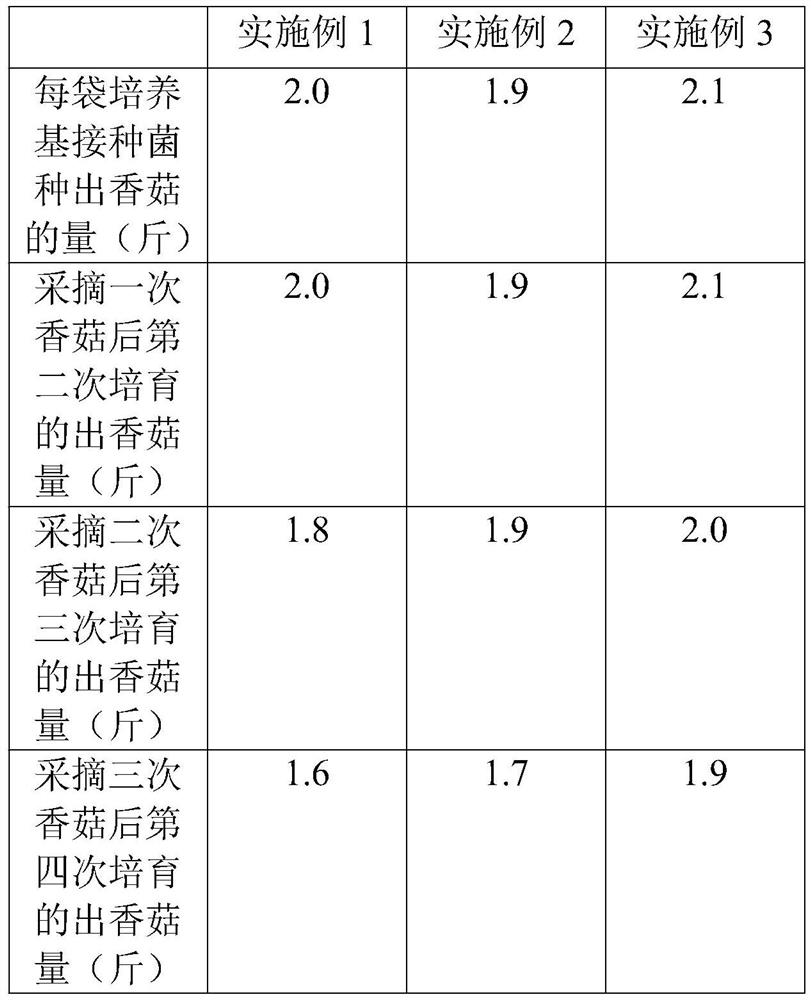

Examples

Embodiment 1

[0018] Raw materials are taken by weight percentage: 60Kg of sawdust of Chinese oak, 10Kg of wheat bran, 0.5 Kg of gypsum, and 0.5Kg of lime;

[0019] Blending and fermentation: first mix sawdust, wheat bran, and gypsum evenly, then cover with plastic film, add water at room temperature and stack for anaerobic fermentation for 5-10 days, then add lime to mix evenly, and test and adjust the pH value at the same time 6.5-7.8, the moisture content of the medium is 50-60%;

[0020] Bagging and sterilization: put the fermented medium into the culture bag and press it tightly, fill each bag with 0.6kg of medium, cover the surface with cotton or sawdust at the mouth of the bag after filling the medium, and finally put the medium Put the bag into a sterilization container, first sterilize at 105-110°C under normal pressure for 8-12 hours, then sterilize at a pressure of 0.11-0.15Mpa and a temperature of 90-95°C for 3 hours, and the sterilization is complete Then seal the medium bag t...

Embodiment 2

[0022] Raw materials are taken by weight percentage: 85Kg of sawdust of Chinese oak, 30Kg of wheat bran, 2Kg of gypsum, and 2Kg of lime;

[0023] Blending and fermentation: first mix sawdust, wheat bran, and gypsum evenly, then cover with plastic film, add water at room temperature and stack for anaerobic fermentation for 5-10 days, then add lime to mix evenly, and test and adjust the pH value at the same time 6.5-7.8, the moisture content of the medium is 50-60%;

[0024] Bagging and sterilization: put the fermented medium into the culture bag and press it tightly, fill each bag with 0.8kg of medium, cover the surface with cotton or sawdust at the mouth of the bag after filling the medium, and finally put the medium Put the bag into a sterilization container, first sterilize at 105-110°C under normal pressure for 8-12 hours, then sterilize at a pressure of 0.11-0.15Mpa and a temperature of 90-95°C for 3 hours, and the sterilization is complete Then seal the medium bag tightl...

Embodiment 3

[0026] Raw materials are taken by weight percentage: 78Kg of sawdust of Chinese oak, 20Kg of bran, 1Kg of gypsum, and 1Kg of lime;

[0027] Blending and fermentation: first mix sawdust, wheat bran, and gypsum evenly, then cover with plastic film, add water at room temperature and stack for anaerobic fermentation for 5-10 days, then add lime to mix evenly, and test and adjust the pH value at the same time 6.5-7.8, the moisture content of the medium is 50-60%;

[0028] Bagging and sterilization: put the fermented medium into the culture bag and press it tightly, fill each bag with 0.7kg of medium, cover the surface with cotton or sawdust at the mouth of the bag after filling the medium, and finally put the medium Put the bag into a sterilization container, first sterilize at 105-110°C under normal pressure for 8-12 hours, then sterilize at a pressure of 0.11-0.15Mpa and a temperature of 90-95°C for 3 hours, and the sterilization is complete Then seal the medium bag tightly.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com