Preparation method of high-strength biological glass bone bracket with regular-hole distribution

A bioglass and pore distribution technology, applied in the field of bioengineering, can solve the problems of insufficient scaffold biological activity, inability to adapt to rapid prototyping, and insufficient compressive strength, and achieve high compressive strength, good biological activity, and good biological Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: The preparation of the three-dimensional connected scaffold consists of the following five steps.

[0029] (1) Preparation of glass powder

[0030]Weigh and weigh 3.8185g anhydrous sodium carbonate, 9.9587g anhydrous potassium carbonate, 1.7502g basic magnesium carbonate, 19.8328g calcium carbonate, 7.9781g strontium carbonate, 9.7420g silicon dioxide, 41.2991g boric acid, 5.6206g dihydrogen phosphate sodium. After uniform mixing and grinding, the ingredients were placed in a platinum crucible and kept at 1200°C for 30 min; then the obtained glass liquid was poured on a steel plate and quenched to obtain a glass block. The obtained glass blocks are coarsely crushed by a horizontal ball mill, finely crushed by a ball mill and sieved to obtain glass powder with a final particle size of 0.05-5 μm.

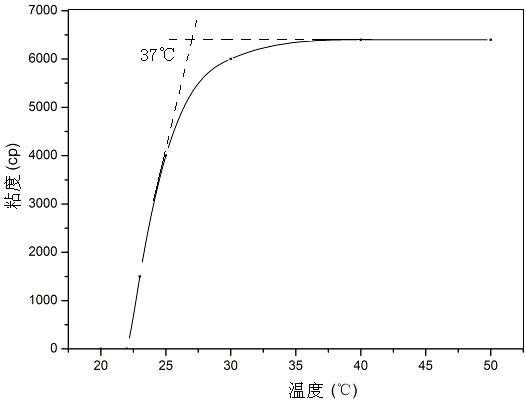

[0031] (2) Preparation of propylene glycol block polyether organic compound solution and determination of phase transition temperature

[0032] Take 50ml of tol...

Embodiment 2

[0041] Example 2: Determination of the pore size, porosity and strength of the scaffold

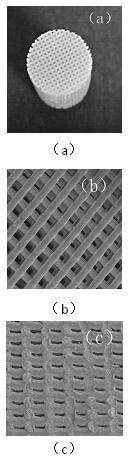

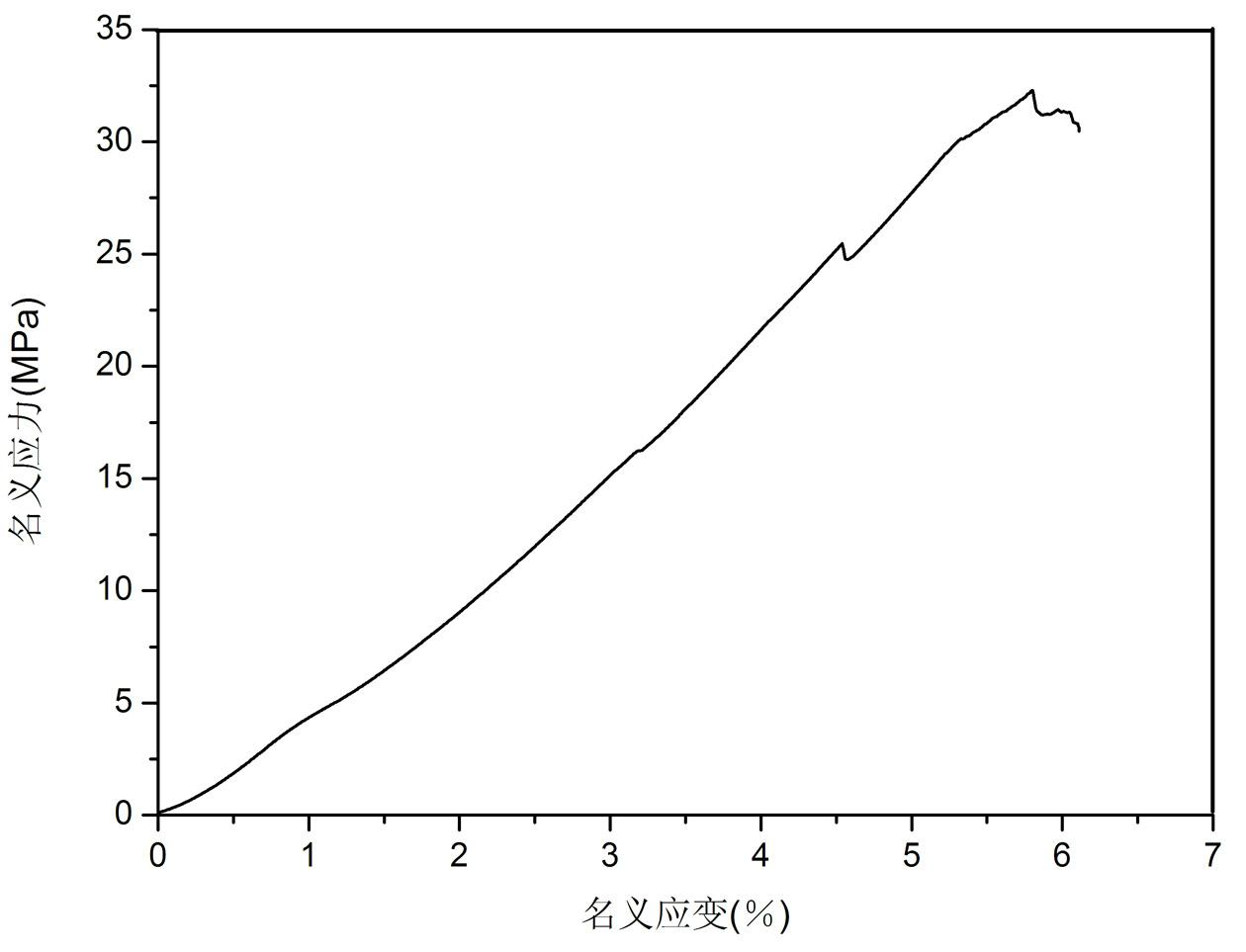

[0042] According to the method described in Example 1, a three-dimensional connected scaffold was prepared. Referring to the national standard GBT 5164-1985 "Determination of Porosity of Permeable Sintered Metal Materials", the porosity of the scaffold was measured, and the results showed that the porosity of the scaffold was 60%, and the maximum pore size was 400 μm, which was comparable to that of figure 1 SEM observations of B and C are consistent. Utilize the compressive strength tester to measure the support compressive strength in embodiment 1 to be 30MPa (see image 3 ).

Embodiment 3

[0043] Embodiment 3: the mensuration of biological property:

[0044] According to the method described in Example 1, a three-dimensional connected scaffold was prepared. The bioactivity, biodegradability and biocompatibility tests were carried out on the prepared scaffold.

[0045] Make XRD analysis to the support that makes, and compare with glass powder (see Figure 4 ), indicating that after a series of thermal processing, the obtained scaffold is still in the glass phase. Then the stent was soaked in a physiological simulation solution at a temperature of 37°C. After 20 days, the stent was taken out, and the reaction process and post-reaction products were characterized by XRD and FTIR (see Figure 5 , and 6), the XRD spectrum of the product shows a typical hydroxyapatite crystal spectrum, and the FTIR spectrum of the product shows a typical hydroxyapatite infrared spectrum. The results show that the borate glass bioactive scaffold sample can be converted into strontiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com