Method for testing shrinkage cracking performance of cement paste or mortar

A technology of shrinkage cracking and cement paste, which is applied in the fields of building materials and civil engineering, can solve the problems of long test period, long cracking time, and ring manufacturing error, and achieve the effect of shortening the test period and accelerating cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention can be used for the shrinkage cracking test of cement paste or mortar. When doing shrinkage cracking tests of different materials, or when the tests have special requirements, the size of the test mold can be changed as needed. The specific embodiment of the present invention is described below:

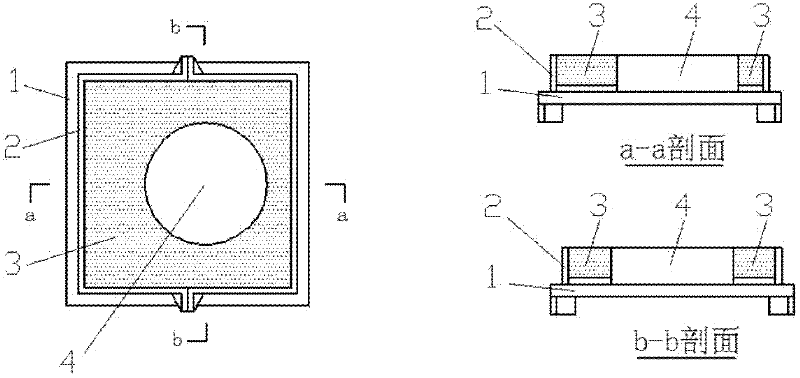

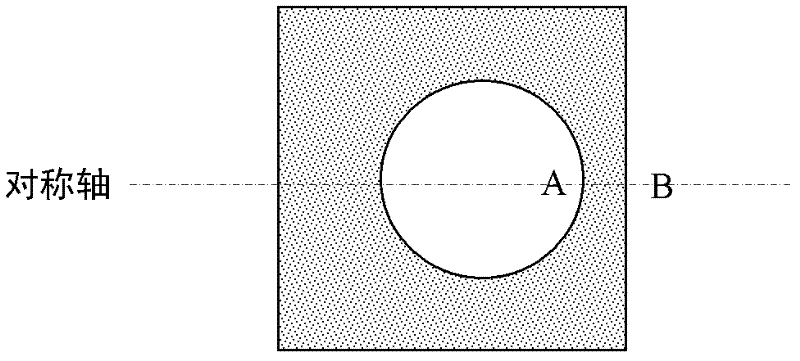

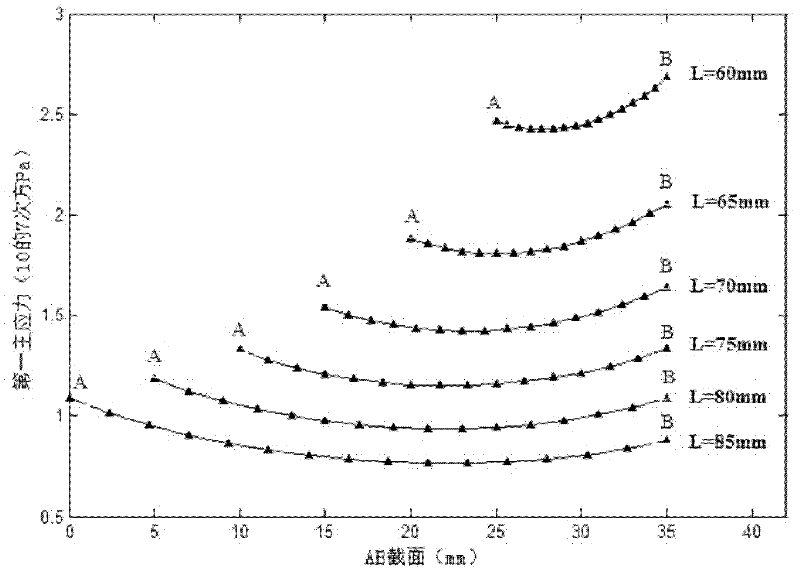

[0024] use as figure 1 The mold shown is used to form test pieces to study the shrinkage cracking performance of cement paste or mortar. The size of the mold needs to meet the thickness of the test piece is greater than or equal to 5 times the maximum particle size of the test sand, and the ratio of the inner circle diameter to the side length of the test piece i Satisfy: 0.5figure 2 As shown, the outer boundary of the test piece formed by the mold is a square, and the inner boundary is a circle. The circle is not in the center of the square, but is in a one-way eccentric position. Before the test piece is formed, first apply a layer of release agent on the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com