Method for preparing low-stress micro-tensile test sample with mesh support frame

A supporting frame and micro-stretching technology, which is applied in the field of preparation of low-stress micro-tensile specimens, can solve the problems of incompatibility with the preparation process of Cu-TSV micro-tensile specimens, cumbersome data processing, etc., and achieve the dispersion of shear stress , reduce the shear area, reduce the effect of stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) After cleaning the 3-inch glass substrate, spin-coat AZ4630 photoresist at a speed of 1200 rpm for 30 seconds as a sacrificial layer, with a thickness of about 10 μm, and then pre-bake it at 110°C 1h to improve the bonding force between photoresist sacrificial layer and glass substrate and subsequent metal layer;

[0032] (2) 0.8 μm metal Ti is sputtered on the photoresist sacrificial layer, and the glass substrate is placed in 5Vol.% glacial acetic acid, 1Vol.% hydrofluoric acid, 1Vol.% hydrogen peroxide and 0.05wt% dodecylsulfonic acid Perform Ti surface activation treatment in a mixed solution of sodium for 50s, and then bake at 60°C for 30min;

[0033] (3) Throw AZ4630 photoresist at a speed of 1200 rpm on the surface activation treatment Ti layer for 30 seconds, then sequentially perform exposure and development for 150s, and realize micro-stretching according to the shape of the micro-stretching sample designed by the mask plate Patterning of the photoresist ...

Embodiment 2

[0039] (1) After cleaning the 4-inch glass substrate, repeat the spin-coating photoresist treatment and drying treatment as in step (1) in Example 1;

[0040] (2) sputtering on photoresist sacrificial layer Metal Ti, repeat the Ti surface activation treatment and oven dry treatment as step (2) among the embodiment 1;

[0041] (3) According to the method of step (3) in embodiment 1, obtain the patterning of microtensile sample layer photoresist structure;

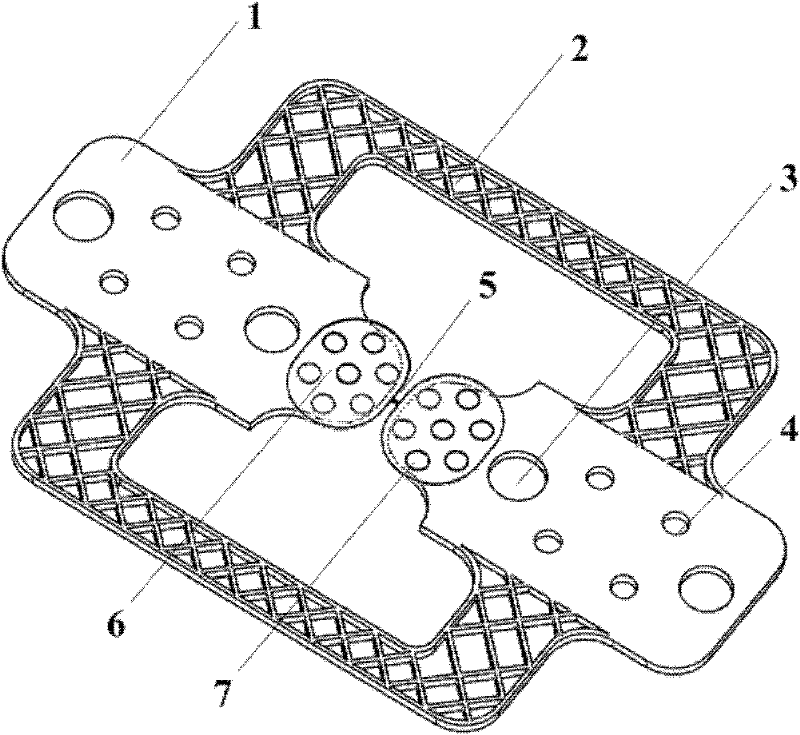

[0042] (4) Utilize the electrochemical deposition technology, on the titanium hydride film layer that has been processed, at the electroplating temperature of 20 ℃, the plating solution stirring speed of 350 rpm, 5mA / cm 2 Under the condition of the current density, using methanesulfonate copper plating solution to electroplate out Figure 4 The Cu-TSV micro-tensile sample layer in the medium includes a micro-tensile sample 5 and a rectangular support platform 8, and its thickness is 6 μm;

[0043] (5) According to the meth...

Embodiment 3

[0046] (1) After the 6-inch glass substrate is cleaned, repeat the spin-coating photoresist treatment and drying treatment of step (1) in Example 1;

[0047] (2) Sputtering on photoresist sacrificial layer Metal Ti, repeat the Ti surface activation treatment and oven dry treatment as step (2) among the embodiment 1;

[0048] (3) According to the method of step (3) in Example 1, the patterning of the photoresist structure of the micro-tensile sample layer is obtained, the shape of the micro-tensile sample layer array is basically consistent with the shape of the support frame layer, only Reserve a processing gap of 100 μm at both ends of the film sample;

[0049] (4) Utilize the electrochemical deposition technology, on the titanium hydride film layer that has been processed, at the electroplating temperature of 20 ℃, the plating solution stirring speed of 350 rpm, 15mA / cm 2 Under the condition of the current density, using methanesulfonate copper plating solution to electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com