Method for measuring fineness of raw silks in real time and device of method

A technology for real-time measurement of raw silk, applied in non-contact measurement of raw silk fineness, measurement of raw silk or fiber fineness, and dynamic fields, which can solve the problem of large dispersion of transparency and refractive index, inability to detect raw silk knots, and inability to accurately reflect raw silk, etc. problem, achieve the effect of suppressing the interference of ambient stray light, realizing dynamic real-time measurement, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

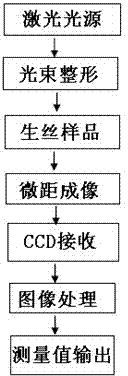

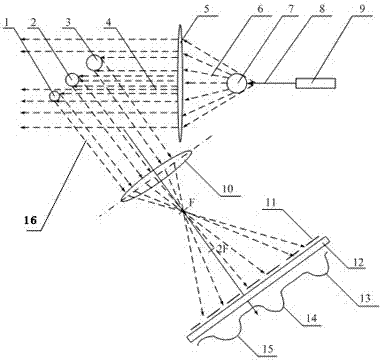

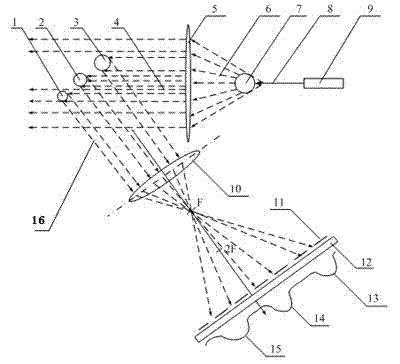

[0021] See attached figure 1 , which is a functional module diagram of a real-time measurement device for raw silk fineness provided in this embodiment; the measurement device includes an optical measurement part composed of a laser light source module, a beam shaping module, a macro imaging module and a CCD receiving module, and an image processing module And the measured value output module constitutes the data processing and output part. The semiconductor laser LD is used as the light source for the measurement of this system. Since the LD light source has certain divergence and elliptical spots, it will affect the measurement effect. Therefore, this embodiment uses a cylindrical optical lens. When the laser beam passing through the thin diaphragm passes through The optical lens produces a certain angle of divergence, and the larger the diameter of the cylinder, the smaller the divergence angle. A convex lens is placed in the diverging light path so that the focal point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com