Carbon/carbon composite material ultrahigh temperature oxidation resistant coating and preparation method thereof

A carbon composite material and anti-oxidation coating technology, which is applied in the field of ultra-high temperature anti-oxidation coating preparation, can solve the problem of low bonding strength, low viscosity of oxidation products, and inability to improve the ultra-high temperature oxidation resistance of ZrB2-SiC coating essentially and other problems, to achieve the effect of good ultra-high temperature mechanical properties and high coating bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

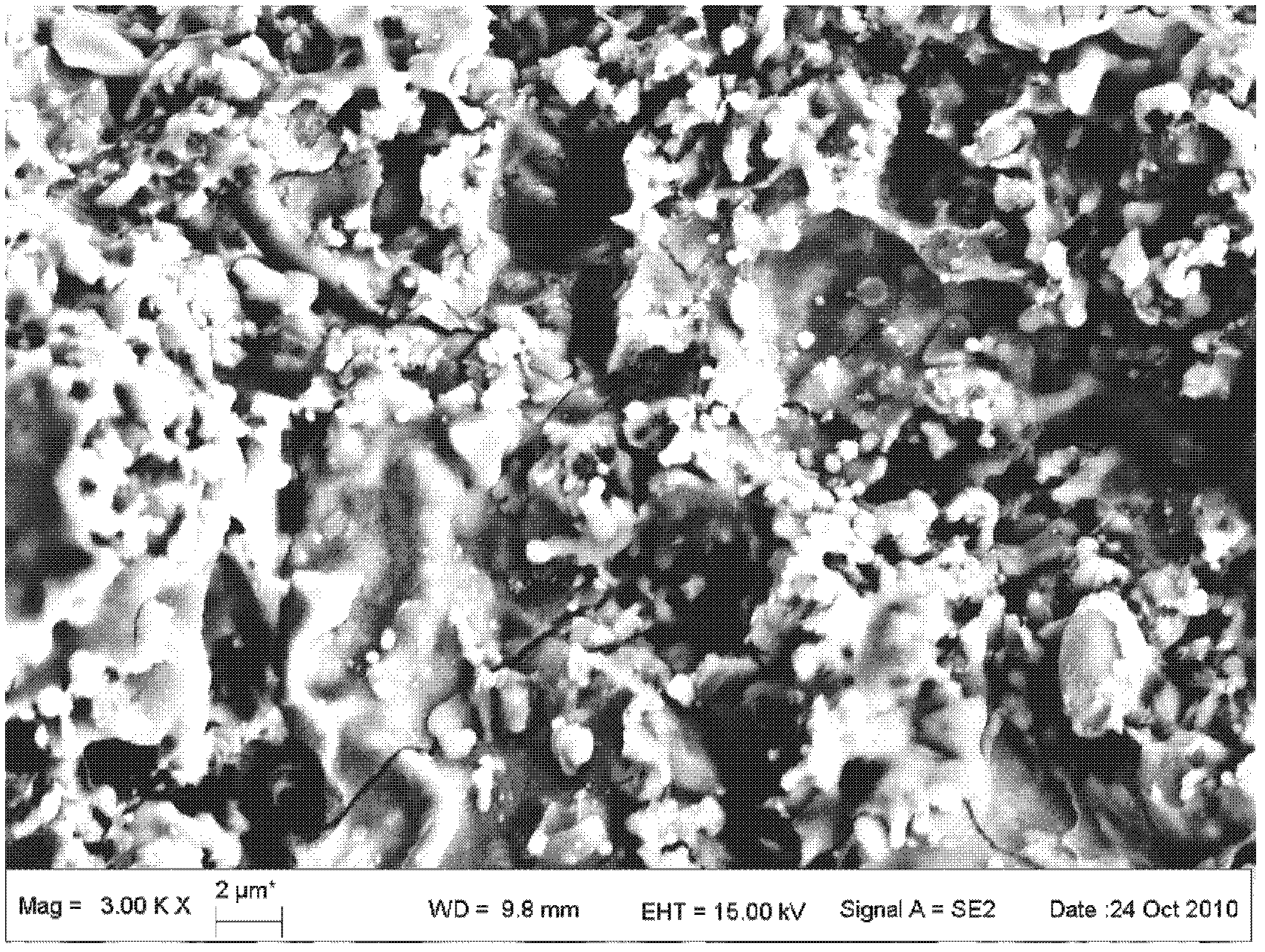

Image

Examples

Embodiment 1

[0028] The carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is composed of the following components in volume percentage: ZrB 2 60%, SiC 15%, TaB 2 15%, Sc 2 o 3 10%.

[0029] The preparation method of the carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is:

[0030] Step 1. After polishing the carbon / carbon composite material, ultrasonically clean it in acetone, and then dry it in an oven;

[0031] Step 2, ZrB with a mass purity of 99.9% and an average particle size of 3 μm 2 Powder, SiC powder with a mass purity of 99.9% and an average particle size of 1 μm, TaB with a mass purity of 99.9% and an average particle size of 2 μm 2 Powder, and Sc with a mass purity of 99.6% and an average particle size of 1.5 μm 2 o 3 The powder is put into a ball mill tank according to the volume percentage, and the ethanol solution with a mass percentage of polyvinylpyrrolidone of 15% is used as a dispers...

Embodiment 2

[0036] The carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is composed of the following components in volume percentage: ZrB 2 50%, SiC 20%, TaB 2 18%, Sc 2 o 3 12%.

[0037] The preparation method of the carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is:

[0038] Step 1. After polishing the carbon / carbon composite material, ultrasonically clean it in acetone, and then dry it in an oven;

[0039] Step 2, ZrB with a mass purity of 99.9% and an average particle size of 1.5 μm 2 Powder, SiC powder with a mass purity of 99.9% and an average particle size of 0.5 μm, TaB with a mass purity of 99.9% and an average particle size of 1 μm 2 Powder, and Sc with a mass purity of 99.6% and an average particle size of 0.8 μm 2 o 3 Put the powder into a ball mill jar by volume percentage, use polyvinylpyrrolidone as a 5% ethanol solution as a dispersant, SiC balls as a grinding ball, and mix for 48 h...

Embodiment 3

[0044] The carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is composed of the following components in volume percentage: ZrB 2 40%, SiC 25%, TaB 2 20%, Sc 2 o 3 15%.

[0045] The preparation method of the carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is:

[0046] Step 1. After polishing the carbon / carbon composite material, ultrasonically clean it in acetone, and then dry it in an oven;

[0047] Step 2, ZrB with a mass purity of 99.9% and an average particle size of 0.5 μm 2 Powder, SiC powder with a mass purity of 99.9% and an average particle size of 0.1 μm, TaB with a mass purity of 99.9% and an average particle size of 0.1 μm 2 Powder, and Sc with a mass purity of 99.6% and an average particle size of 0.1 μm 2 o 3 The powder is put into a ball mill tank according to the volume percentage, the ethanol solution with a mass percentage of polyvinylpyrrolidone of 20% is used as a dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com