Pre-processing reinforced type impregnating agent for basalt fiber chopped spun yarn and preparation method of pre-processing reinforced type impregnating agent

A basalt fiber and reinforced technology, which is applied in the field of pretreatment reinforced sizing agent and preparation for basalt fiber chopped spun yarn, can solve the problems of affecting product performance, unsatisfactory folding and abrasion resistance, etc., and achieves increased bonding strength, The effect of small strength loss and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

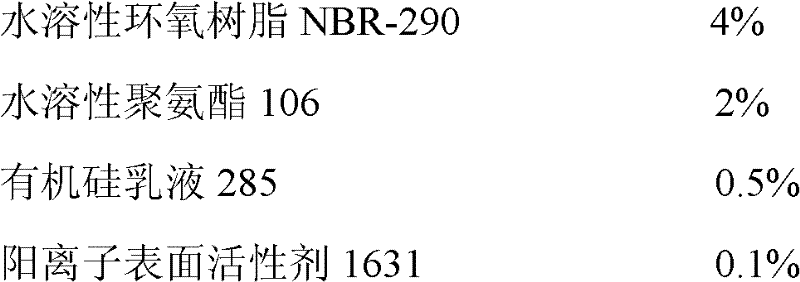

[0037] The pretreatment enhanced sizing agent for the basalt fiber chopped spun yarn has the following ingredients in percentage by weight:

[0038]

[0039]

[0040] Its preparation process is as follows: (calculated according to the preparation of 100 kg of sizing agent)

[0041] (1) Weigh 5 kg of demineralized water, add glacial acetic acid, slowly add the silane coupling agent under stirring conditions, and stir for 30 minutes until the aqueous solution is clear and transparent;

[0042] (2) Stir the water-soluble epoxy resin evenly with 40 kilograms of demineralized water of 60 ± 5 degrees;

[0043] (3) Stir the water-soluble polyurethane evenly with 20 kilograms of demineralized water of 60 ± 5 degrees;

[0044] (4) Stir the silicone emulsion evenly with 5 kg of demineralized water;

[0045] (5) Stir the cationic surfactant evenly with 3 kilograms of demineralized water of 90 ± 5 degrees;

[0046] (6) Stir the antistatic agent evenly with 5 kg of demineralized w...

Embodiment 2

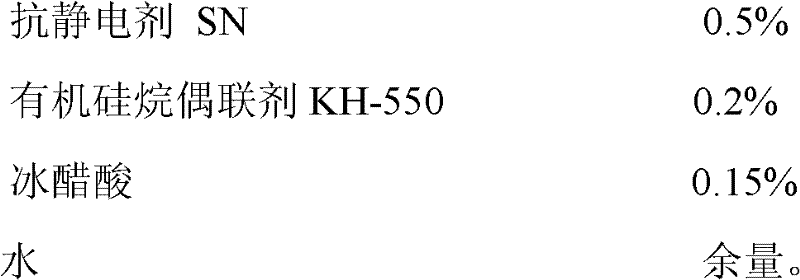

[0049] The pretreatment enhanced sizing agent for the basalt fiber chopped spun yarn has the following ingredients in percentage by weight:

[0050]

[0051] Its preparation process is as follows: (calculated according to the preparation of 100 kg of sizing agent)

[0052] (1) Weigh 5 kg of demineralized water, add glacial acetic acid, slowly add the silane coupling agent under stirring conditions, and stir for 30 minutes until the aqueous solution is clear and transparent;

[0053](2) Stir the water-soluble epoxy resin evenly with 20 kilograms of demineralized water of 65 ± 5 degrees;

[0054] (3) Stir the water-soluble polyurethane evenly with 40 kilograms of demineralized water of 60 ± 5 degrees;

[0055] (4) Stir the silicone emulsion evenly with 8 kg of demineralized water;

[0056] (5) Stir the antistatic agent evenly with 3 kg of demineralized water at 55 ± 5 degrees;

[0057] (6) The materials prepared by steps (1), (2), (3), (4), (5) and (6) are added to the pre...

Embodiment 3

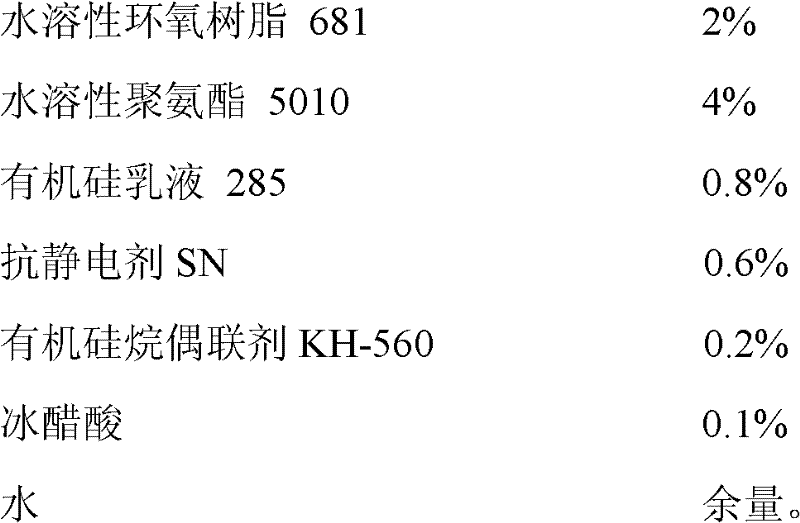

[0059] The pretreatment enhanced sizing agent for the basalt fiber chopped spun yarn has the following ingredients in percentage by weight:

[0060]

[0061] Its preparation process is as follows: (calculated according to the preparation of 100 kg of sizing agent)

[0062] (1) Weigh 5 kg of demineralized water, add glacial acetic acid, slowly add the silane coupling agent under stirring conditions, and stir for 30 minutes until the aqueous solution is clear and transparent;

[0063] (2) water-soluble epoxy resin is stirred evenly with the demineralized water of 55 ± 5 degrees of 35 kilograms;

[0064] (3) Stir the water-soluble polyurethane evenly with 25 kilograms of demineralized water of 55 ± 5 degrees;

[0065] (4) Stir the silicone emulsion evenly with 2.5 kg of demineralized water;

[0066] (5) Stir the cationic surfactant evenly with 2 kilograms of demineralized water of 95 ± 5 degrees;

[0067] (6) Stir the antistatic agent evenly with 5 kg of demineralized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com