Method for controllably synthesizing nano zinc oxide based on solvent heat

A nano-zinc oxide and solvothermal technology is applied in the synthesis and application of nanomaterials, which can solve the problems of complex synthesis process, difficult synthesis, and many raw materials, and achieve uniform product distribution, convenient post-processing and high controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

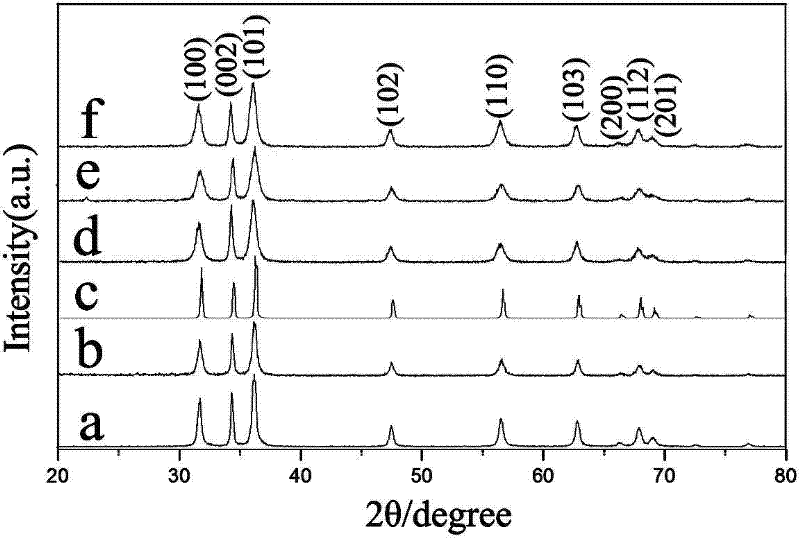

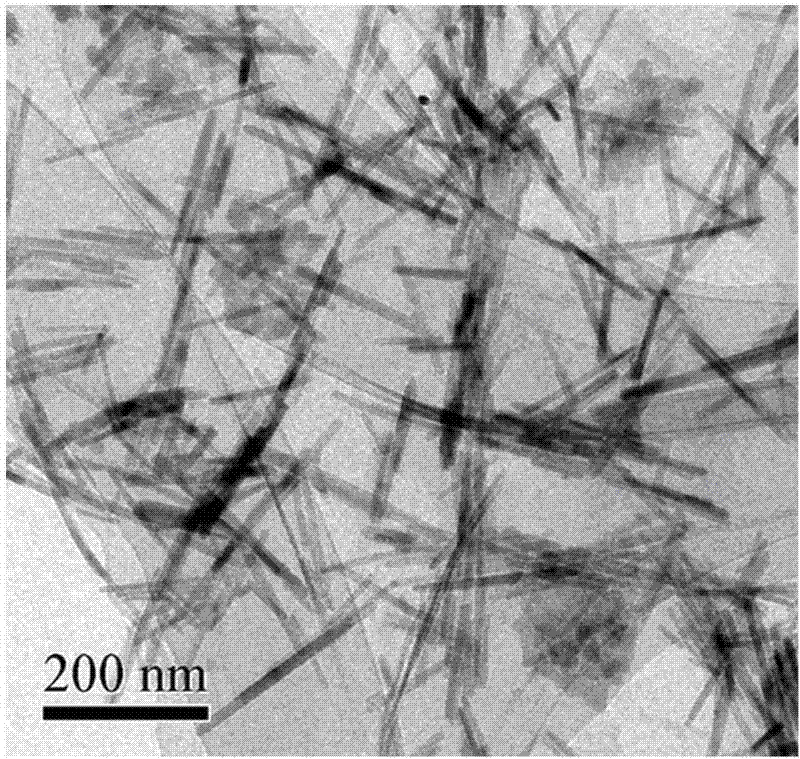

Image

Examples

Embodiment 1

[0038] (1) 30 milliliters of ethanol with a mass fraction of 95% is added to a 50 milliliter hydrothermal kettle, and then 1.74×10 -5 mol (0.625 grams) of polyvinylpyrrolidone (PVP) was stirred and dissolved, and then added 5.7×10 -4 mol (0.125 g) of zinc acetate dihydrate was stirred and dissolved, and finally added 1.88×10 -2 mol (0.75 grams) of sodium hydroxide and stirred at room temperature for 20 minutes;

[0039] (2) after airtight hydrothermal kettle, it is placed in baking oven, is warming up to 100 ℃, insulation reaction 1 hour;

[0040] (3) After the reaction is completed, cool the hydrothermal kettle to room temperature naturally in an oven, open the hydrothermal kettle and pour off the upper layer solution, and keep the precipitated product; first wash the product with deionized water, disperse it by ultrasonic vibration, and collect it by centrifugal sedimentation Precipitate, the obtained precipitate was separated by filtration and then washed with 95% ethanol...

Embodiment 2

[0042](1) 60 milliliters of ethanol with a mass fraction of 95% is added to a 100 milliliter hydrothermal kettle, and then 3.48×10 -5 mol (1.25 grams) of polyvinylpyrrolidone (PVP) was stirred and dissolved, and then added 1.14×10 -3 mol (0.25 g) of zinc acetate dihydrate was stirred and dissolved, and finally added 3.76×10 -2 mol (1.5 grams) of sodium hydroxide and stirred at room temperature for 20 minutes;

[0043] (2) after airtight hydrothermal kettle, it is placed in baking oven, is warming up to 120 ℃, insulation reaction 2 hours;

[0044] (3) After the reaction is completed, cool the hydrothermal kettle to room temperature naturally in an oven, open the hydrothermal kettle and pour off the upper layer solution, and keep the precipitated product; first wash the product with deionized water, disperse it by ultrasonic vibration, and collect it by centrifugal sedimentation Precipitate, the obtained precipitate was separated by filtration and then washed with 95% ethanol ...

Embodiment 3

[0046] (1) 30 milliliters of ethanol with a mass fraction of 95% is added to a 50 milliliter hydrothermal kettle, and then 1.74×10 -5 mol (0.625 grams) of polyvinylpyrrolidone (PVP) was stirred and dissolved, and then added 5.7×10 -4 mol (0.125 g) of zinc acetate dihydrate was stirred and dissolved, and finally added 1.88×10 -2 mol (0.75 grams) of sodium hydroxide and stirred at room temperature for 30 minutes;

[0047] (2) place it in the oven after airtight hydrothermal kettle, be warming up to 140 ℃, insulation reaction 1 hour;

[0048] (3) After the reaction is completed, cool the hydrothermal kettle to room temperature naturally in an oven, open the hydrothermal kettle and pour off the upper layer solution, and keep the precipitated product; first wash the product with deionized water, disperse it by ultrasonic vibration, and collect it by centrifugal sedimentation Precipitate, the obtained precipitate was separated by filtration and then washed with 95% ethanol and dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com