Preparation method and application of titanium dioxide loaded ruthenium catalyst

A technology of titanium dioxide and ruthenium catalysts, which is applied in the field of high-activity supported ruthenium catalysts and their preparation, which can solve the problems of extremely high equipment and process requirements, difficulty in industrial application, and large ruthenium particle size, so as to achieve simple equipment and process and facilitate industrialization Production, effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] At 25°C, measure 80ml of 2.0g / L ruthenium nitrate solution into a 300ml beaker, add 5g of titanium dioxide, ultrasonicate for 10min, and magnetically stir for 20min; use 1M sodium hydroxide solution to adjust the pH value of the suspension to 6, and stir Irradiated under 250W ultraviolet light for 4 hours under the same conditions. After the reaction, the slurry was washed by centrifugation for 3 times, dried at 110°C, taken out after 10 hours, roasted in air at 400°C for 4 hours, and reduced with a mixed gas of hydrogen and nitrogen with a hydrogen volume concentration of 0.4 at 400°C for 3 hours. TiO2-supported ruthenium catalyst was obtained; it was taken out and stored in a vacuum desiccator.

[0018] Titanium dioxide is nano-mixed titanium dioxide P25.

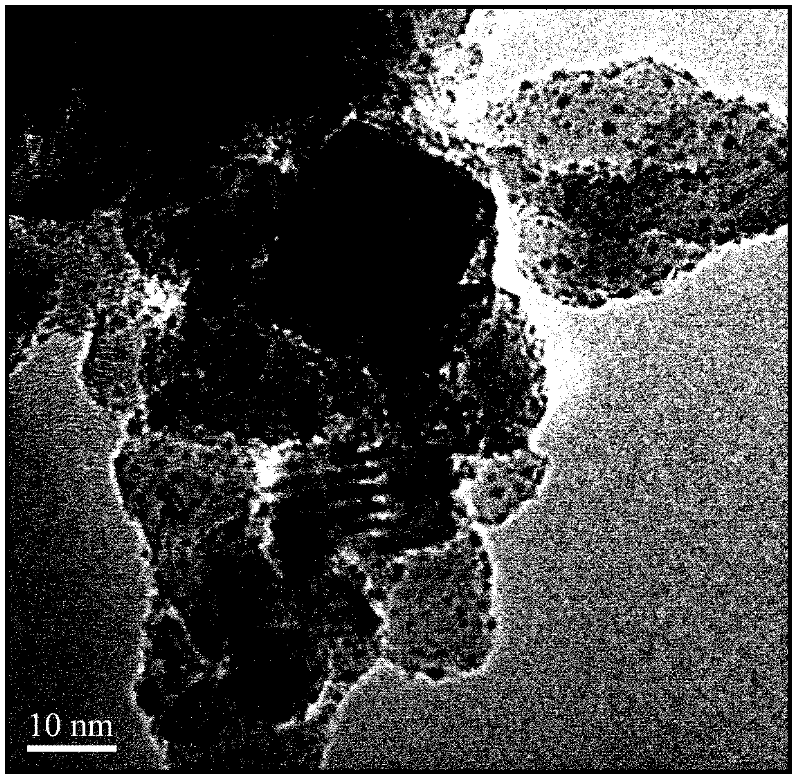

[0019] In the prepared titania-supported ruthenium catalyst, the active component ruthenium is uniformly dispersed on the surface of the carrier titania with a nanoscale grain size.

[0020] The titanium dioxide s...

Embodiment 2

[0023] At 25°C, measure 80ml of 2.0g / L ruthenium nitrosyl nitrate solution, add 5g of titanium dioxide, ultrasonicate for 10min, and magnetically stir for 20min; use 1M sodium hydroxide solution to adjust the pH value of the suspension to 9, stirring conditions Irradiated under 650W ultraviolet light for 4h, after the reaction, the slurry was centrifugally washed 3 times, dried at 110°C, taken out after 10h, roasted in air at 400°C for 4h, and reduced at 400°C for 3h to obtain Titanium dioxide supported ruthenium catalyst; take it out and put it into a vacuum desiccator for preservation.

[0024] Titanium dioxide is nano-mixed titanium dioxide P25.

[0025] In the prepared titania-supported ruthenium catalyst, the active component ruthenium is uniformly dispersed on the surface of the carrier titania with a nanoscale grain size.

[0026] The titanium dioxide supported ruthenium catalyst prepared above is used to catalyze the hydrogenation of carbon dioxide to generate methane...

Embodiment 3

[0029] At 80°C, measure 80ml of 2.0g / L ruthenium chloride solution, add 5g of titanium dioxide, ultrasonicate for 10min, and magnetically stir for 20min; use 1M sodium hydroxide solution to adjust the pH value of the suspension to 9, and stir under Irradiated under 250W ultraviolet light for 4 hours, after the reaction, the slurry was centrifugally washed for 3 times, dried at 110°C, taken out after 10 hours, roasted in air at 550°C for 4 hours, and reduced to 200°C for 5 hours with a mixed gas of hydrogen and nitrogen with a hydrogen volume concentration of 0.4 to obtain a titanium dioxide load. Ruthenium catalyst; take it out and store it in a vacuum desiccator.

[0030] Titanium dioxide is nano-mixed titanium dioxide P25.

[0031] In the prepared titania-supported ruthenium catalyst, the active component ruthenium is uniformly dispersed on the surface of the carrier titania with a nanoscale grain size.

[0032] The titanium dioxide supported ruthenium catalyst prepared abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com