Rotary type continuous feed fixed bed reactor

A fixed-bed reactor, rotary technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unsuitable use of catalysts and catalysts that cannot be replaced, and achieve large-scale production, easy control, and easy popularization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

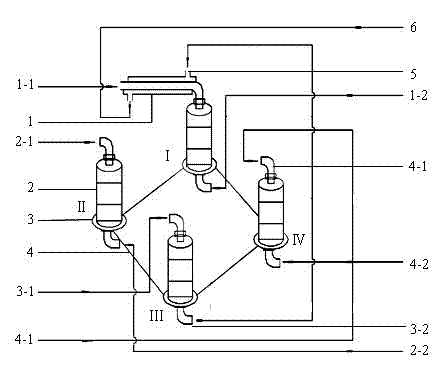

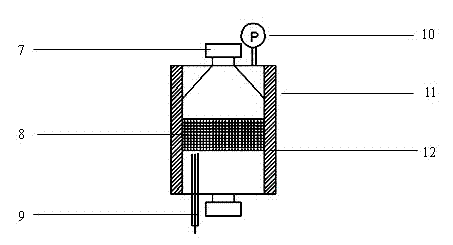

[0028] Embodiment 1: see Figure 1-4 , the rotary continuous feeding fixed bed reactor comprises four reactors 2, four trays 3, a turntable 4, movable sealing joints 7, inlet pipes and exhaust pipes connected to the inlets and outlets of the reactors 2 respectively Trachea, and common power transmission mechanism. The four reaction kettles 2 are uniformly and symmetrically fixed on the turntable 4 via the four trays 3 respectively, and the air inlets at the upper end and the air outlets at the lower end of each reaction kettle 2 respectively pass through movable sealing joints 7, and are connected to the corresponding air inlet pipes at stations Ⅰ-Ⅳ. It is connected with the exhaust pipe; the power transmission mechanism consists of a turntable drive motor, a movable joint drive motor and a corresponding transmission mechanism. The output shaft of the turntable drive motor is connected with the rotating shaft of the turntable 4 through a gear transmission mechanism to drive th...

Embodiment 2

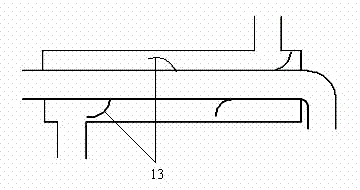

[0030] Example 2: see Figure 1-4 , The structure of the rotary continuous feed fixed-bed reactor is the same as in Example 1. Used for methane oxidation reaction to produce synthesis gas, raw material gas methane, catalyst is Cu-Zn-Al; movable sealing joint 7, each intake pipe and exhaust pipe are made of copper, and the diameter of each intake pipe and exhaust pipe is 15mm, 12 pieces of spiral fins 13 are evenly installed on the inner tube wall of the heat exchange sleeve 1; the drive motor drives the movable sealing joint 7 to move up and down through the gear shifting and rack transmission mechanism, so as to realize the connection with the reactor. Docking or separation of air port or exhaust port.

Embodiment 3

[0031] Embodiment 3: see Figure 1-4 , The structure of the rotary continuous feed fixed-bed reactor is the same as in Example 1. Used for methane oxidation reaction to produce synthesis gas, raw material gas methane, catalyst is Cu-Zn-Al, movable sealing joint 7, the material of each intake pipe and exhaust pipe is aluminum alloy, the diameter of each intake pipe and exhaust pipe 16 pieces of spiral fins 13 are evenly installed on the inner wall of the heat exchange sleeve 1, and the drive motor drives the turntable 4 to rotate through a chain transmission mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com