Separation and purification method for dendrobium polysaccharide

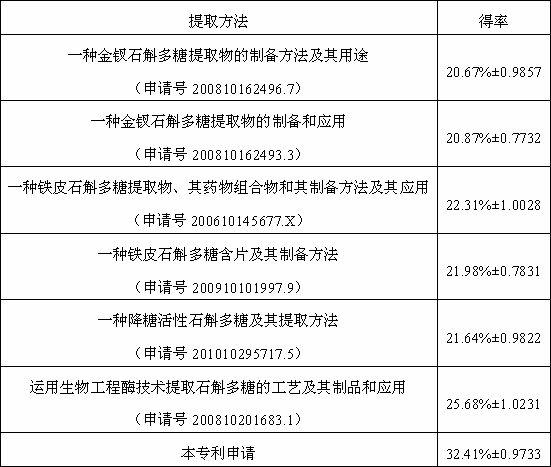

A technology for the separation and purification of dendrobium polysaccharides, which is applied in the field of separation and purification of dendrobium polysaccharides, can solve problems such as lack of innovation, and achieve the effects of preserving the biological activity of dendrobium polysaccharides, increasing the extraction rate, and increasing the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The dried dendrobium sample was pulverized with a pulverizer, sieved, and 100 g of 80 mesh dendrobium powder was taken. Reflux twice with 15 times of 95% ethanol, filter, and place in a cool and ventilated place to volatilize the organic solvent to obtain medicinal residues.

[0027] Microwave-assisted solvent extraction, microwave time 75 seconds, microwave intensity 800W, add 15 times the mass of distilled water.

[0028] Add 2% cellulase, adjust the pH of the solution to 6.0, and keep the water temperature at 40°C for 2 hours of enzymatic hydrolysis.

[0029] Filter with double-layer filter cloth, extract the filter residue with 20 times distilled water, the temperature of the water bath is 90°C, and extract twice with water, the first time is 2 hours, and the second time is 1 hour. Suction filtration, discard the residue, collect the suction filtrate, and combine the suction filtrate to obtain the extract.

[0030] Concentrate the extract in vacuum to 1 / 6 of the o...

Embodiment 2

[0032] The dried dendrobium sample was pulverized with a pulverizer, sieved, and 100 g of 80 mesh dendrobium powder was taken. Reflux twice with 10 times of absolute ethanol, filter, and evaporate the organic solvent to obtain medicinal residues. Microwave-assisted solvent extraction, microwave time 75 seconds, microwave intensity 800W, add 15 times the mass of distilled water. Filter with double-layer filter cloth, add 2% cellulase, adjust the pH value of the solution to 6.0, and keep the water temperature at 40°C for 2 hours for enzymatic hydrolysis. Filter with double-layer filter cloth, extract the filter residue once with 30 times distilled water, and the temperature of the water bath is 100°C; after the water extraction is completed, filter with suction, collect the filtrate to obtain the extract.

[0033] The extract was concentrated in vacuum to 1 / 6 of the original volume, and 95% ethanol was added until the ethanol concentration reached 80%. Alcohol precipitation at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com