Technological method for preparing sulbactam by means of recycle hydrogen reduction

A process method and technology for circulating hydrogen, which are applied in the synthesis of sulbactam and the synthesis of pharmaceutical organic chemistry, can solve the problems of long operation time, difficult to meet requirements, and high equipment requirements, improve yield and quality, and reduce by-product generation. , mild conditions and friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

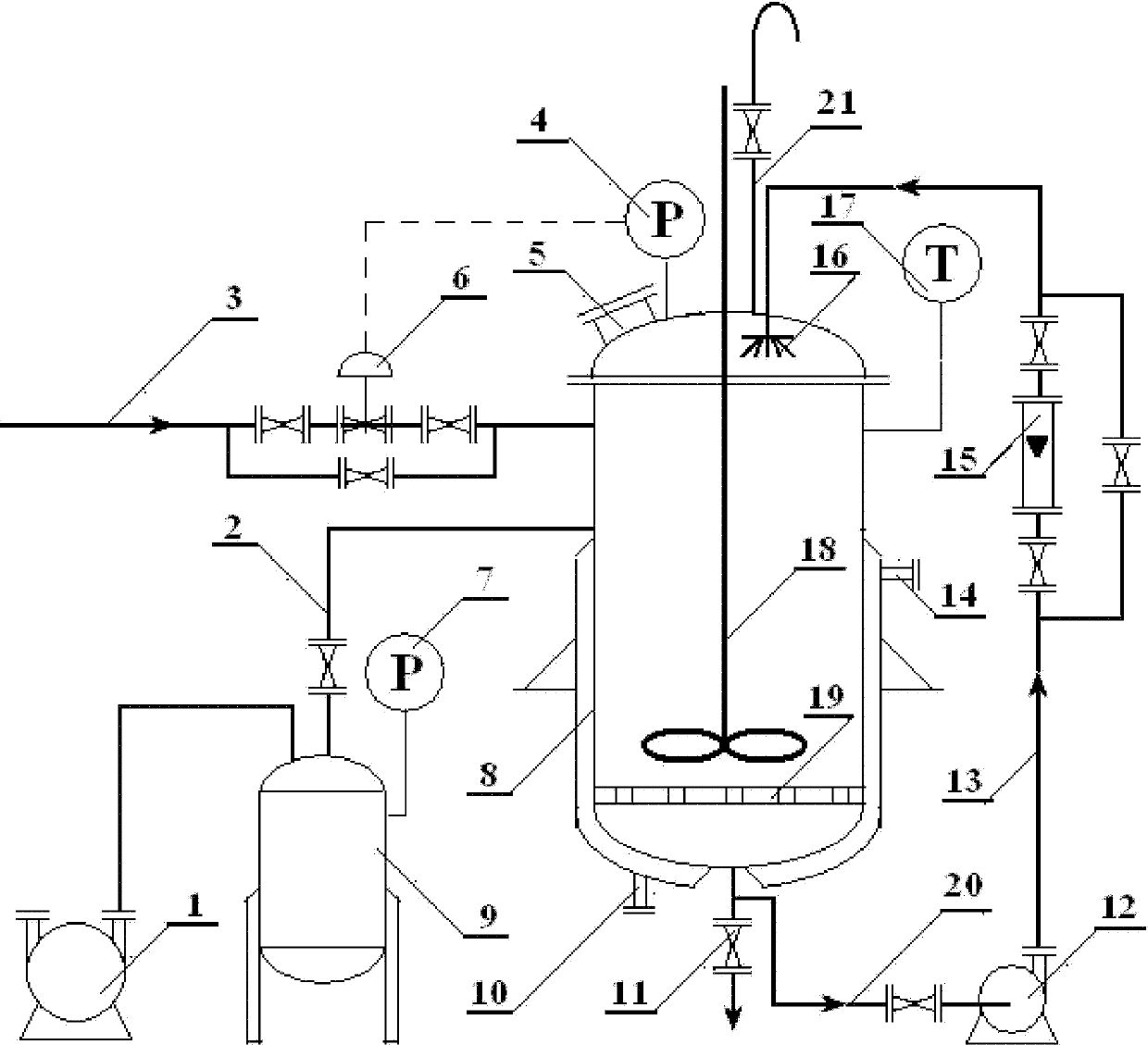

[0037] as attached figure 1 Shown, the liquid circulation system that adopts when the present invention is implemented is as follows:

[0038]The hydrogenation reactor mainly includes a reactor 8, a vacuum system, a hydrogen supply system, and a liquid circulation system; the vacuum system is connected to the reactor 8 through a vacuum pipeline 2, and the hydrogen supply system is connected to the reactor through a hydrogen supply pipeline 3. The tanks 8 are connected; the top of the reactor 8 is provided with a feeding port 5; the liquid circulation system sucks the liquid material in the reactor 8, and then sprays it out from the circulating medium jet nozzle 16 located at the top of the reactor 8.

[0039] The liquid circulation system includes a circulation pump 12, a volume flow meter 15 and a circulation medium jet nozzle 16 connected in series through pipelines; the circulation pump 12 is connected with the reaction liquid discharge port at the bottom of the reactor 8 t...

Embodiment 2

[0049] Dissolve 90g of dibromopenicillane sulfonic acid in 300mL of ethyl acetate, add it to a 1000mL magnetically stirred high-pressure hydrogenation reactor with a grid-type filter buffer plate at the bottom, and add 4g of Raney nickel catalyst with an average diameter of 20 mesh, and close the high-pressure still, use a vacuum pump to evacuate the high-pressure hydrogenation reactor to an absolute pressure of 90Pa, stop vacuuming, feed hydrogen into the hydrogenation reactor and keep the pressure of the reactor at 0.5MPa, open the hydrogenation reactor to circulate the ice salt water in the cooling medium jacket, Control the temperature in the hydrogenation reactor to 0°C. In the state of stirring, turn on the circulating pump, suck out the liquid phase reaction medium from the bottom of the reactor, inject it into the circulating medium jet nozzle on the top of the reactor, and the liquid phase medium with a certain pressure passes through the circulating medium jet nozzle ...

Embodiment 3

[0053] With 145g dibromopenicillane sulfonic acid, 300mL ethyl acetate, add respectively in the 1000mL magnetic stirring high-pressure hydrogenation reactor, utilize embodiment 2 to automatically filter and stay in the Raney nickel catalyst in the hydrogenation reactor, close the autoclave, and vacuum pump When the high-pressure hydrogenation reactor is evacuated to an absolute pressure of 100Pa, stop vacuuming, feed hydrogen into the hydrogenation reactor and keep the pressure of the reactor at 0.8MPa, and use the ice-salt water in the hydrogenation reactor to circulate the cooling medium jacket to adjust the temperature in the hydrogenation reactor is 3°C. Start the stirring and circulation pump to make the reaction medium realize extracorporeal circulation and enter the circulating medium jet nozzle on the top of the reactor. After circulating for 40 minutes, stop the stirring and circulation, and release the pressure of the hydrogenation reactor to normal pressure. Evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com