Preparation method of optical fiber prefabricated rod

A technology of optical fiber prefabricated rods and core rods, applied in glass manufacturing equipment, glass fiber products, manufacturing tools, etc., can solve problems such as clusters, and achieve the effects of suppressing cluster effects, high stability, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

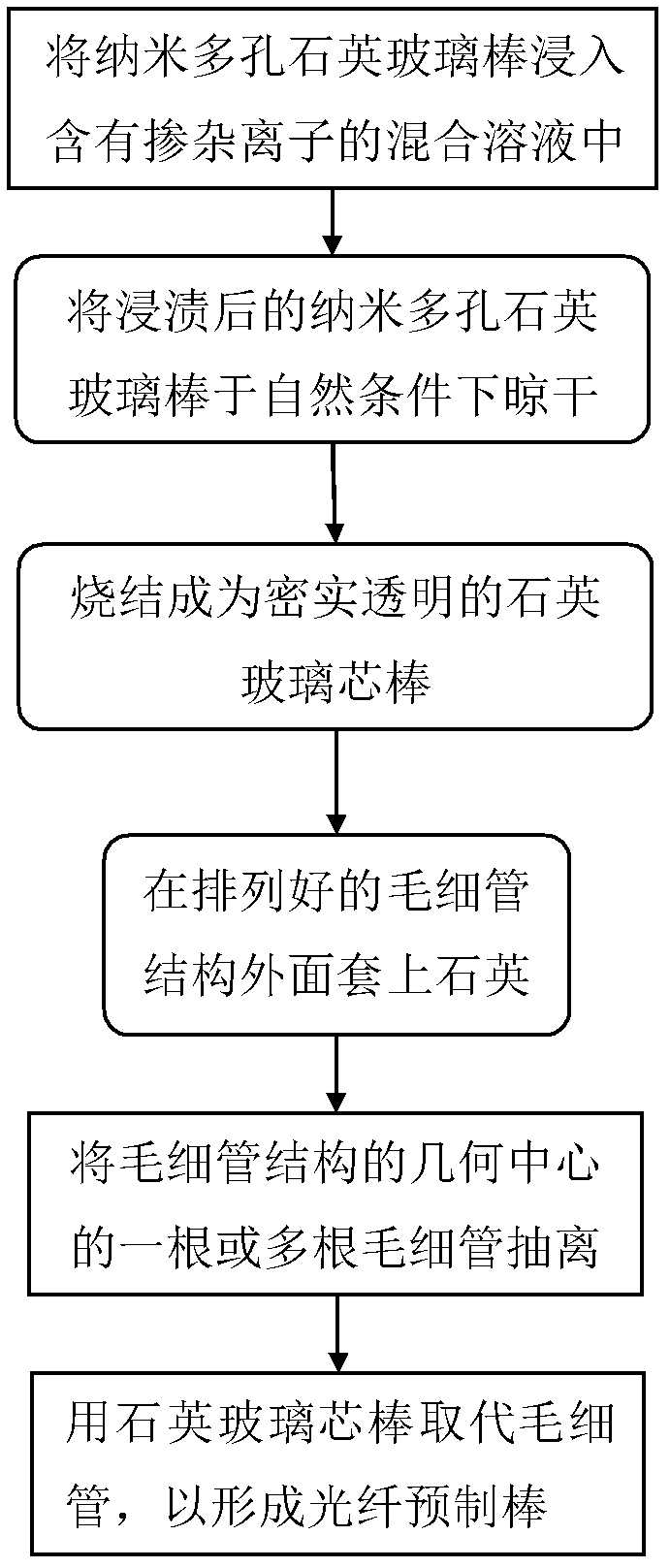

[0020] Such as figure 1 As shown, the preparation method of the optical fiber preform of the present invention comprises the following steps:

[0021] (1) Dip the nanoporous quartz glass rod into a mixed solution containing dopant ions;

[0022] (2) the impregnated nanoporous quartz glass rod is dried under natural conditions;

[0023] (3) The dried nanoporous quartz glass rod is sintered at 1050°C to 1200°C to form a dense and transparent quartz glass core in a vacuum, carbon monoxide, chlorine, helium, argon or nitrogen environment. Great;

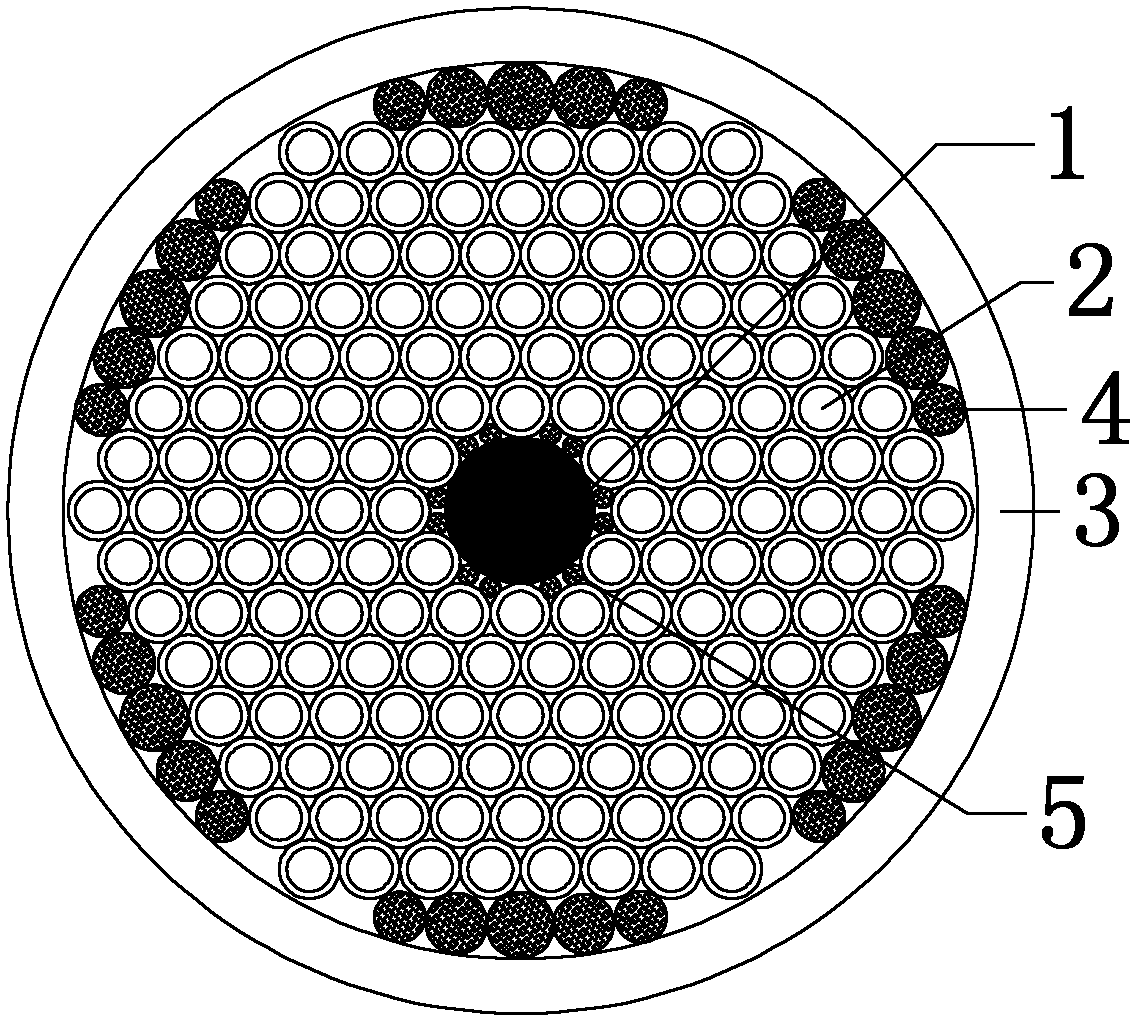

[0024] (4) Put a quartz glass tube on the outside of the arranged capillary structure;

[0025] (5) extracting one or more capillaries at the geometric center of the capillary structure;

[0026] (6) The capillary is replaced by a quartz glass core rod to form an optical fiber preform.

[0027] The heating process in step (3) includes: from room temperature to the interval of 100 degrees Celsius to 200 degrees Celsius, the heating r...

example 1

[0034] First, SiO with a diameter of 2.86mm, a length of 500mm, and an average pore 2 A nanoporous quartz glass rod with a weight percentage of 96% is immersed in a nitric acid solution containing neodymium nitrate and aluminum nitrate, the concentration of neodymium ions in the nitric acid solution is 0.1mol / L, and the concentration of aluminum ions is 0.1mol / L. The immersion time was 150 minutes.

[0035] Thereafter, the impregnated nanoporous silica glass rod was taken out and dried in air.

[0036] After the nanoporous quartz glass rod is completely dry, it is placed in a sintering furnace covered with carbon powder, and the temperature is raised according to the following heating process in a carbon monoxide environment.

[0037] From room temperature (25°C) to 100°C, the heating time is 90 minutes (the heating rate is 0.83°C / min), and the temperature is kept at 100°C for 120 minutes; from 100°C to 600°C, the heating time is 300 minutes (the heating rate is 1.67°C) / min...

example 2

[0044] First, SiO with a diameter of 7mm, a length of 500mm, and an average pore 2 A nanoporous quartz glass rod with a weight percentage of 96% is immersed in an aqueous solution containing ytterbium nitrate and aluminum nitrate, the concentration of ytterbium ions in the aqueous solution is 0.2 mol / L, the concentration of aluminum ions is 0.6 mol / L, and the immersion time is 150 minutes.

[0045]Thereafter, the impregnated nanoporous silica glass rod was taken out and dried in air.

[0046] After the glass is completely dry, it is placed in a vacuumized sintering furnace, and the temperature is raised according to the following heating process:

[0047] From room temperature (25°C) to 200°C, the heating time is 175 minutes (the heating rate is 1°C / min), and the temperature is kept at 200°C for 120 minutes; from 200°C to 750°C, the heating time is 275 minutes (the heating rate is 2°C) / min), kept at 750°C for 90 minutes; from 750°C to 950°C, the heating time was 100 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com