Binding method for capacitive touch screen

A technology of capacitive touch screen and bonding surface, which is applied in the direction of chemical instruments and methods, electrical digital data processing, and input/output process of data processing, etc. Control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

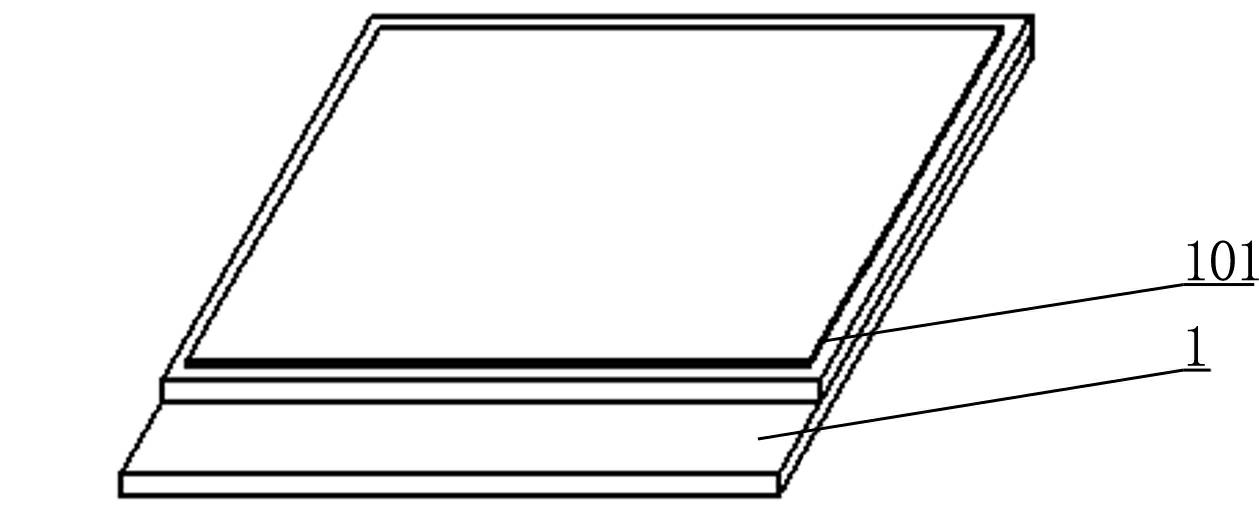

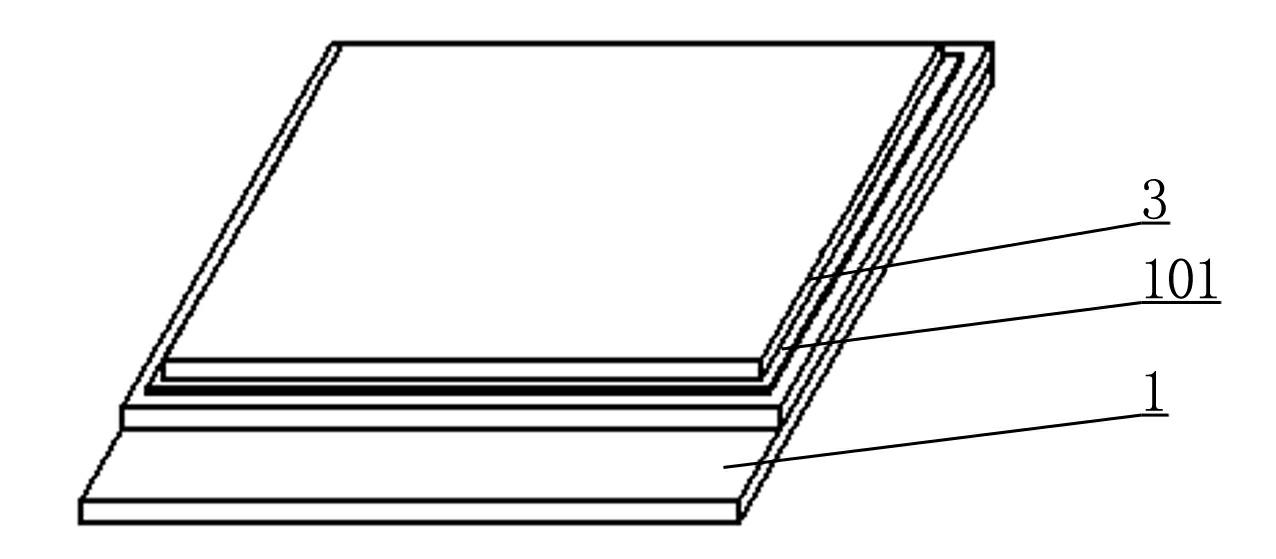

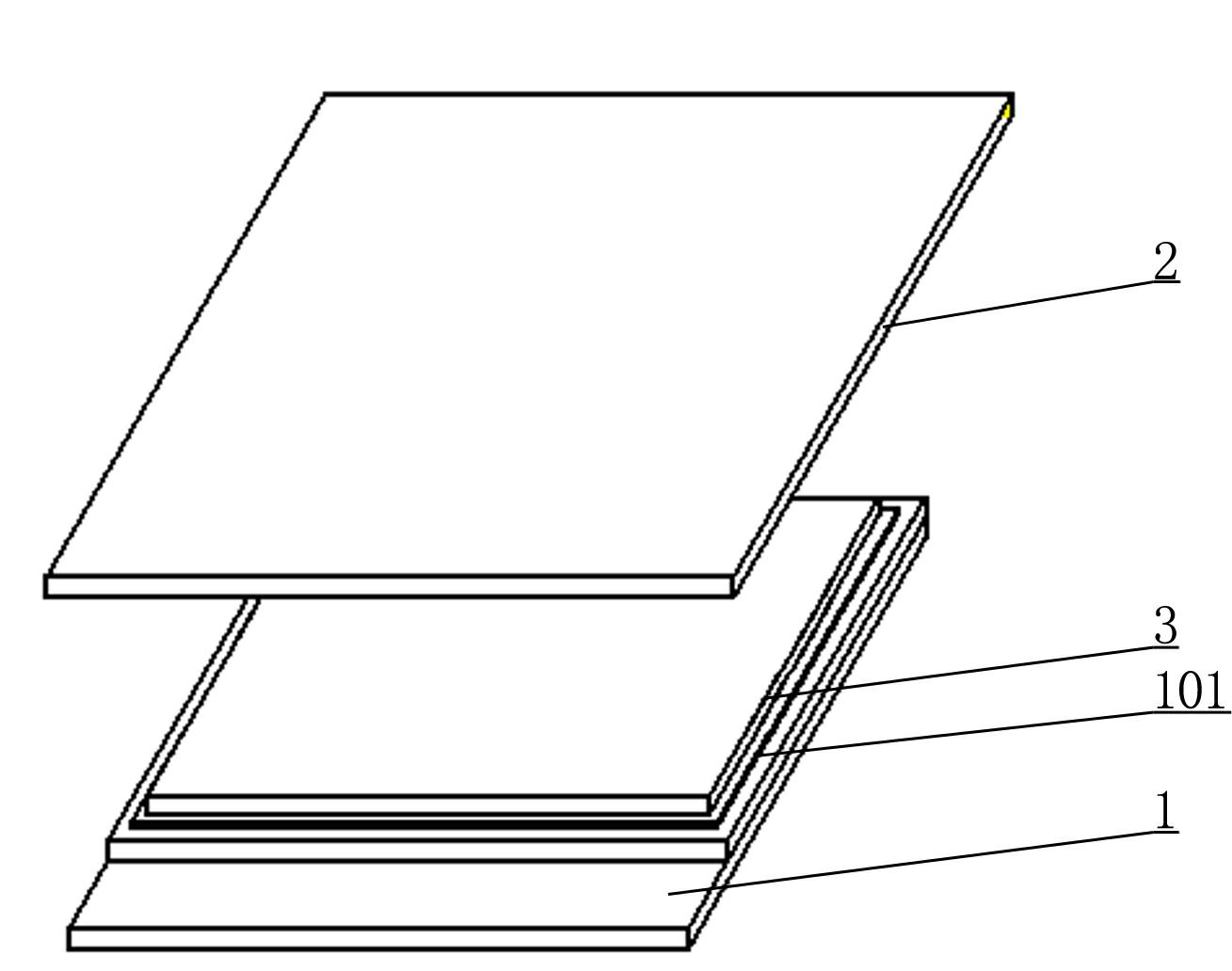

[0043] Such as Figure 1 to Figure 4As shown, in the laminating method of this capacitive touch screen, the first board body 1 is the display screen of the flat panel display, the second board body 2 is the sensing board of the capacitive touch screen, and the first board body 1 and the second board body 2 are bonded together. Integration includes the following steps:

[0044] (1), using polymethyl methacrylate (PMMA) added with ultraviolet curing components, on the bonding surface of the first plate body 1, that is, the outer surface of the polarizer 101 of the display screen is uniformly screen printed One layer of adhesive layer 3 with a thickness of 80um;

[0045] (2), placing the first board and the second board in a vacuum environment with an air pressure of 10Pa;

[0046] (3), the bonding surface of the second plate body 2 is opposite to the bonding surface of the first plate body 1, and the second plate body 2 is pressed on the adhesive layer 3, the first plate body ...

Embodiment 2

[0052] Such as Figure 5 to Figure 8 As shown, in the pasting method of this capacitive touch screen, the first plate body 11 is a cover plate in a joint state, and the second plate body 12 is an induction plate in a joint state, and the first plate body 11 and the second plate body 12 A cutting line 1101 (1201), a bonding area 1102 (1202) and a non-bonding area 1103 (1203) are respectively provided on the bonding surface of the first plate body 11 and the second plate body 12. The bonding includes the following steps:

[0053] (1), using polymethyl methacrylate (PMMA) added with ultraviolet curing components, evenly screen-print a layer of 30um thickness on the bonding area 1102 on the bonding surface of the first plate body 11. an adhesive layer 13;

[0054] (1-a), using ultraviolet light to pre-cure the first adhesive layer 13 within 1 minute, so that the first adhesive layer 13 loses fluidity, but still maintains a certain degree of plasticity and viscosity;

[0055] (1-...

Embodiment 3

[0062] refer to Figure 1 to Figure 4 , under the same situation as Embodiment 1 in other respects, the difference is that: the first plate body is a cover plate; in step (1), the coating method of polymethyl methacrylate (PMMA) is: adopt a The glue applicator of the slit-shaped glue nozzle, and fix the position of the glue applicator, the glue nozzle is downward, the first board passes under the glue nozzle at a constant speed, and polymethyl methacrylate (PMMA) flows from the glue nozzle Squeeze out from the gap of the first board, and evenly spread it on the bonding surface of the first board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com