Method for synthesizing hydroxyapatite-titanium oxide composite coating by adopting microarc oxidation method and potentiostatic method

A technology of hydroxyapatite and micro-arc oxidation, which is applied in coatings, electrolytic inorganic material coatings, etc., can solve problems such as low bonding strength and easy peeling off, large differences in properties between coatings and substrate materials, and difficulty in fully satisfying clinical applications. , to achieve the effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

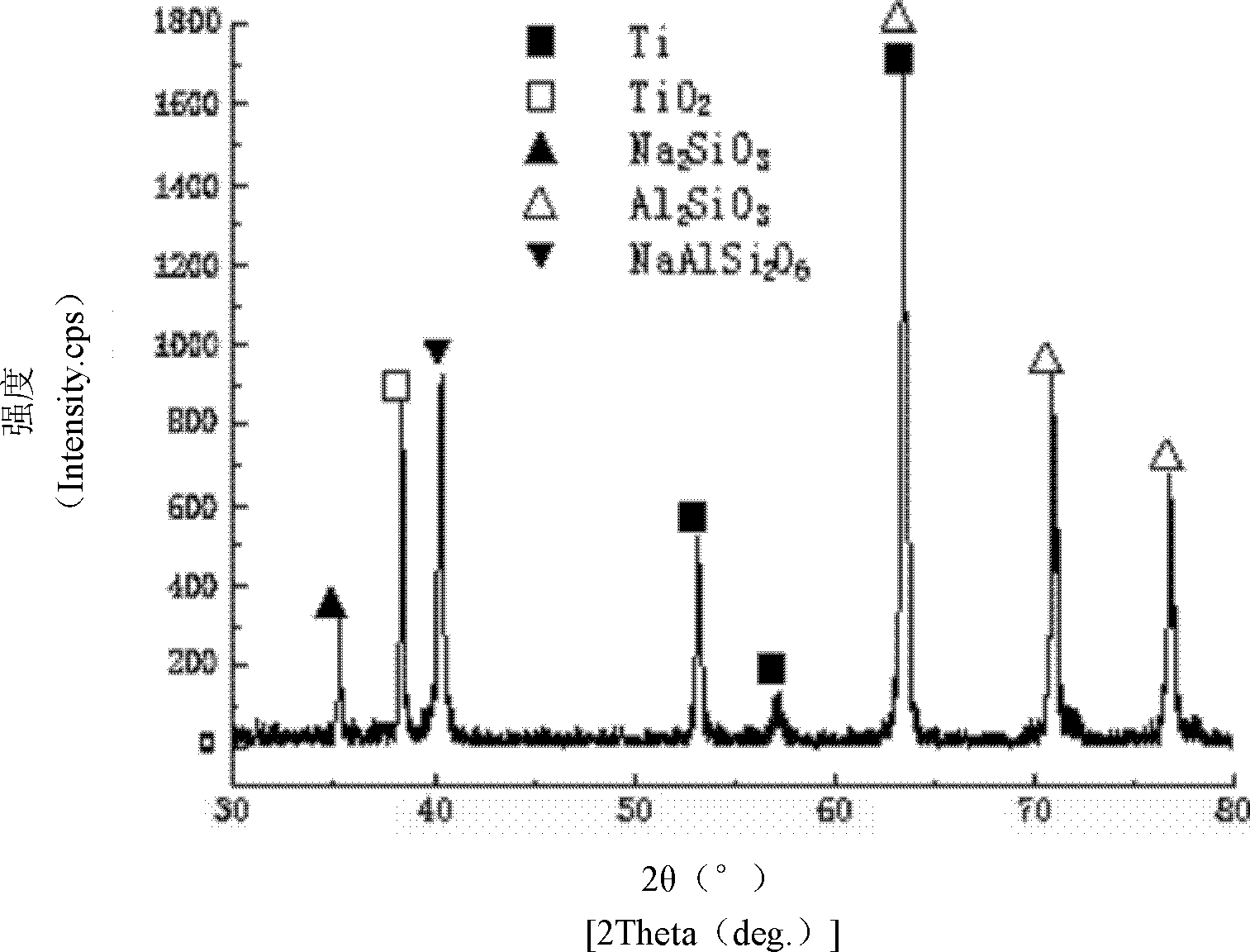

[0022] ① Micro-arc oxidation: The pretreated Ti6Al4V alloy is used as the working electrode, and the brass electrode is used as the auxiliary electrode; 20g / L sodium silicate solution is prepared with deionized water, and a two-electrode system is used for micro-arc oxidation synthesis to obtain a titanium oxide coating. layer of Ti6Al4V alloy;

[0023] The parameters of micro-arc oxidation: the voltage of micro-arc oxidation is 200V, the pulse frequency is 14000Hz, the duty cycle is 40%, and the reaction time is 10min;

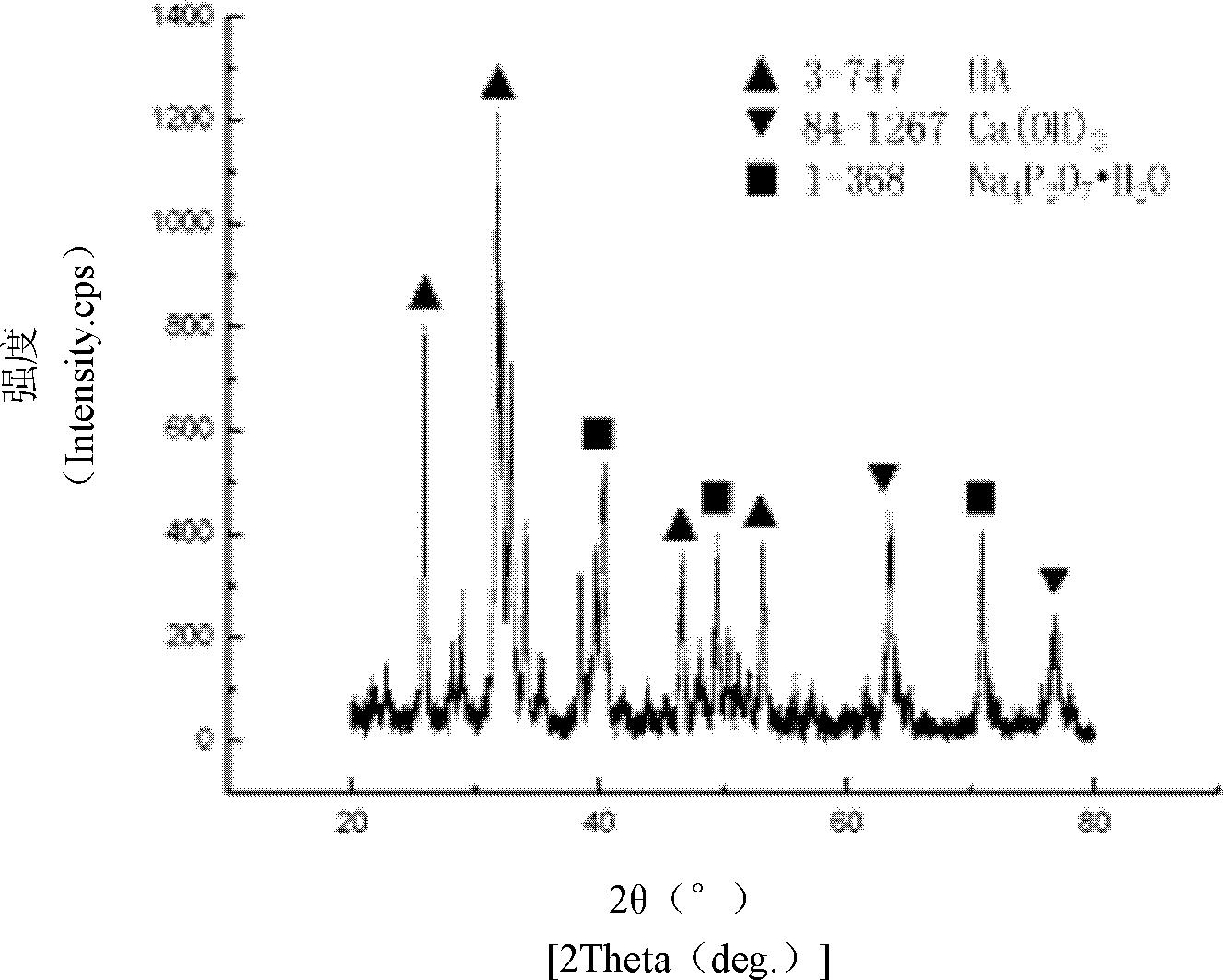

[0024] ②Constant potential electrolysis: with Ca(NO 3 ) 2 , NaH 2 PO 4 and deionized water to configure the electrolyte, the Ca(NO 3 ) 2 The concentration is 0.168mol / L, NaH 2 PO 4 The concentration is 0.100mol / L, stir well; the Ti6Al4V alloy electrode with titanium oxide coating prepared in step ① is used as the working electrode, and the platinum electrode is used as the auxiliary electrode to carry out the constant potential electrolysis reaction. T...

Embodiment 2

[0032] ① Micro-arc oxidation: The treated TiNi alloy is used as the working electrode, and the brass electrode is used as the auxiliary electrode; 20g / L sodium silicate solution is prepared with deionized water, and a two-electrode system is used for micro-arc oxidation synthesis; micro-arc oxidation parameters: The micro-arc oxidation voltage is 200V, the pulse frequency is 14000Hz, the duty cycle is 40%, and the reaction time is 10min;

[0033] ②Ca(NO 3 ) 2 , NaH 2 PO 4 and deionized water to configure the electrolyte, the Ca(NO 3 ) 2 The concentration is 0.168mol / L, NaH 2 PO 4 The concentration is 0.100mol / L, stir well; use the TiNi alloy electrode prepared in step ① as the working electrode, and the platinum electrode as the auxiliary electrode to carry out the constant potential electrolysis reaction. The electrolysis parameters are: the constant potential voltage is -3.25V, and the reaction time is 75min;

[0034] ③Place the TiNi alloy composite material prepared ...

Embodiment 3

[0036] ① Micro-arc oxidation: The pretreated Ti6Al4V alloy is used as the working electrode, and the brass electrode is used as the auxiliary electrode; 20g / L sodium silicate solution is prepared with deionized water, and the two-electrode system is used for micro-arc oxidation synthesis; the parameters of micro-arc oxidation : The micro-arc oxidation voltage is 300V, the pulse frequency is 14000Hz, the duty cycle is 40%, and the reaction time is 10min;

[0037] ②Constant potential electrolysis: with Ca(NO 3 ) 2 , NaH 2 PO 4 and deionized water to configure the electrolyte, the Ca(NO 3 ) 2 The concentration is 0.168mol / L, NaH 2 PO 4 The concentration is 0.100mol / L, stir well; use the Ti6Al4V alloy electrode prepared in step ① as the working electrode, and the platinum electrode as the auxiliary electrode to carry out the constant potential electrolysis reaction. The electrolysis parameters are: the constant potential voltage is -3.0V, and the reaction time is 75min;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com