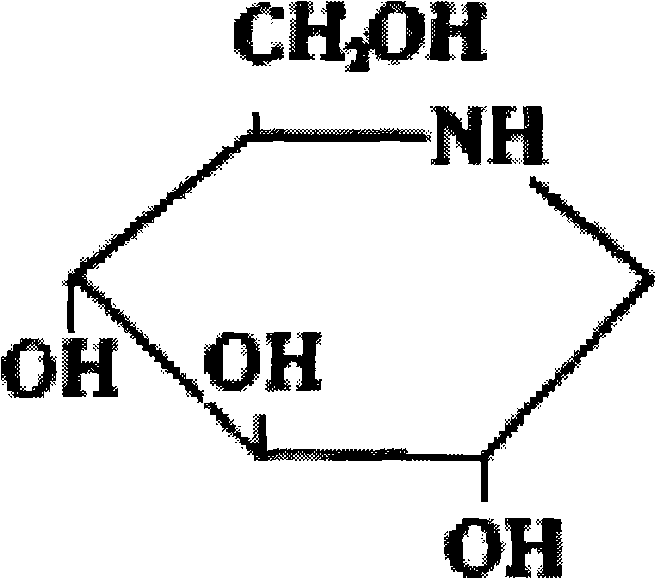

Purification method of deoxynojirimycin

A technology of deoxynojirimycin and purification method, which is applied in the field of biology and new medicine, can solve problems such as difficulty in meeting medical application standards, difficulty in realizing industrialization promotion, and destruction of target product structure, so as to reduce extraction cost, low cost, and equipment typical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] After removing impurities and drying the mulberry leaves, crush them through a 40-mesh sieve, take 1kg of mulberry leaf powder, add 40L of 65% ethanol to soak for 30 minutes, and then ultrasonically extract 3 times, each ultrasonic power 125W, temperature 70°C, time 30min, suction filtration to obtain corresponding solid and liquid phases.

[0030] (1) Preparation of 1-deoxynojirimycin

[0031] The liquid phase obtained by ultrasonic crushing and centrifugation of mulberry leaves is recovered with a rotary evaporator and concentrated to a small volume, and the precipitate is removed by centrifugation. The supernatant is passed through a chromatographic column equipped with 732H cationic resin, and washed with distilled water until the effluent is colorless. , eluted with 0.25mol / L ammonia water, the elution rate was 1 times the column volume / h, the elution rate was 1-2mL / min, and the eluate was collected.

[0032] Concentrate the ammonia water eluate to about 1L, adjus...

Embodiment 2

[0039] After removing impurities and drying the mulberry leaves, crush them through a 40-mesh sieve, take 1kg of mulberry leaf powder, add 40L of 60% ethanol to soak for 40min, and extract by ultrasonic wave for 3 times, each time with ultrasonic power of 125W, temperature 70°C, time 30min, and suction filtration to obtain the corresponding solid and liquid phases.

[0040] (1) Preparation of 1-deoxynojirimycin

[0041] The liquid phase part obtained by ultrasonic crushing and centrifugation of mulberry leaves is recovered with a rotary evaporator and concentrated to a small volume, and the precipitate is removed by centrifugation. Until the color is gone, elute with 0.25mol / L ammonia water, the elution rate is 1 times the column volume / h, the elution rate is 1-2mL / min, and the eluate is collected.

[0042]Concentrate the ammonia water eluate to about 1L, adjust the pH value to 7.0 with 2mol / L acetic acid, add 0.25L chloroform extract in two times, stir evenly, let stand for ...

Embodiment 3

[0049] After removing impurities and drying the mulberry leaves, crush them through a 40-mesh sieve, take 1kg of mulberry leaf powder, add 40L of 65% ethanol to soak for 30min, and extract by ultrasonic wave 3 times, each time with ultrasonic power of 125W, temperature 70°C, time 30min, and suction filtration to obtain the corresponding solid and liquid phases.

[0050] (1) Preparation of 1-deoxynojirimycin

[0051] The liquid phase obtained by ultrasonic crushing and centrifugation of mulberry leaves is recovered with a rotary evaporator and concentrated to a small volume, and the precipitate is removed by centrifugation. The supernatant is passed through a chromatographic column equipped with 732H cationic resin, and washed with distilled water until the effluent is colorless. , eluted with 0.25mol / L ammonia water, the elution rate was 1 times the column volume / h, the elution rate was 1-2mL / min, and the eluate was collected.

[0052] Concentrate the ammonia water eluate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com