Method for performing comprehensive treatment by utilizing waste water from production of ternary monomer

A technology for production wastewater and comprehensive treatment, applied in extraction water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the loss of effective substances, difficult to extract clean, land and environmental pollution And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

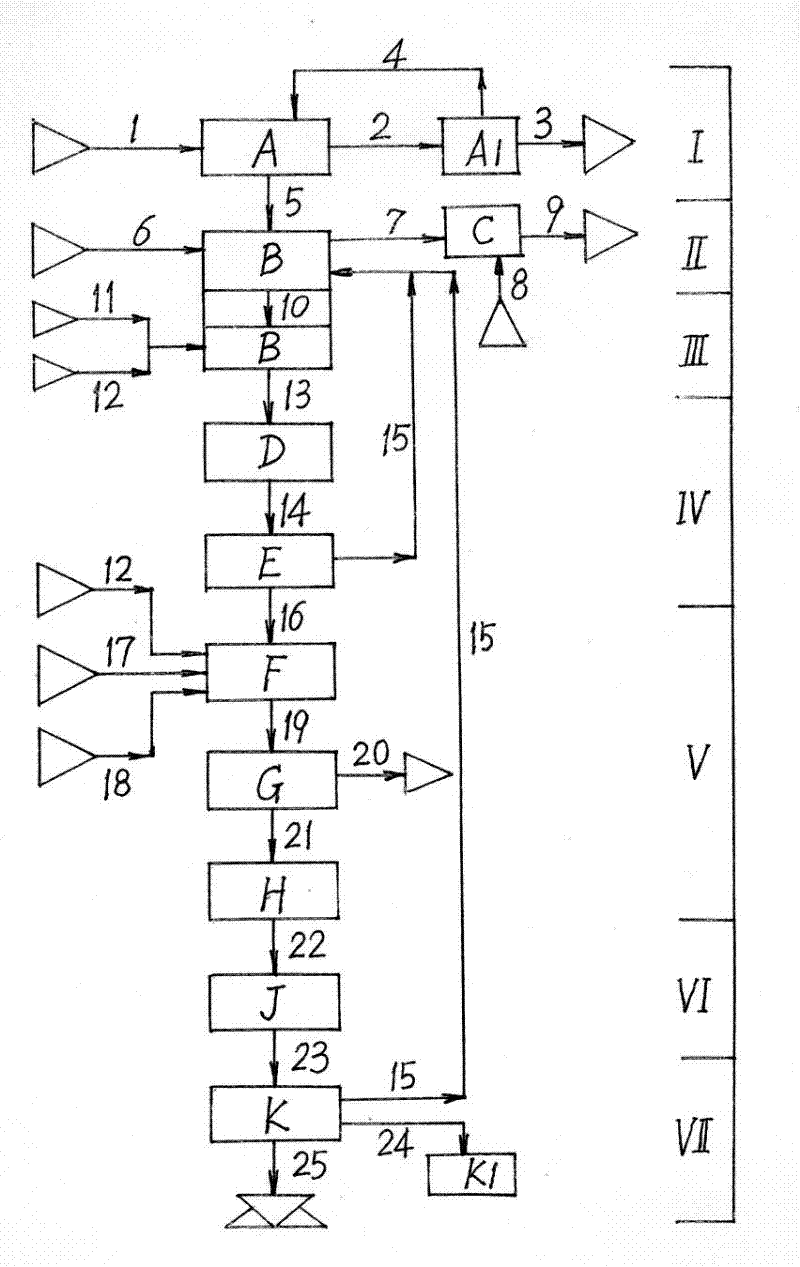

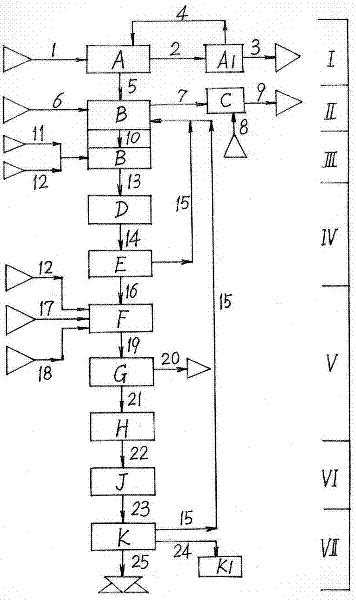

[0008] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0009] Referring to the accompanying drawings, multiple production equipments are connected by pipelines to form a comprehensive processing production line, which is divided into distillation dealcoholization process I, extraction process II, stripping process III, concentration and dehydration process IV, hot-melting fine filtration process V, dehydration process according to the production process Crystallization step VI, preparation of drying step VII. The equipment in the distillation dealcoholization process I includes a crude distillation tower A and a fine distillation tower A1. The process is to add the production wastewater 1 to the crude distillation tower A, set the gas phase temperature at the top of the tower to 75-80°C, and the reflux temperature at the top of the tower to be ≤55°C. After high-temperature distillation with a li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com