Method for preparing black phosphorus of negative electrode materials of high-capacity lithium-ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in the fields of chemical material synthesis and electrochemistry, can solve the problem that high-energy ball milling is difficult to accurately control the internal pressure and temperature of a reaction vessel, and achieves excellent compatibility and improved electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

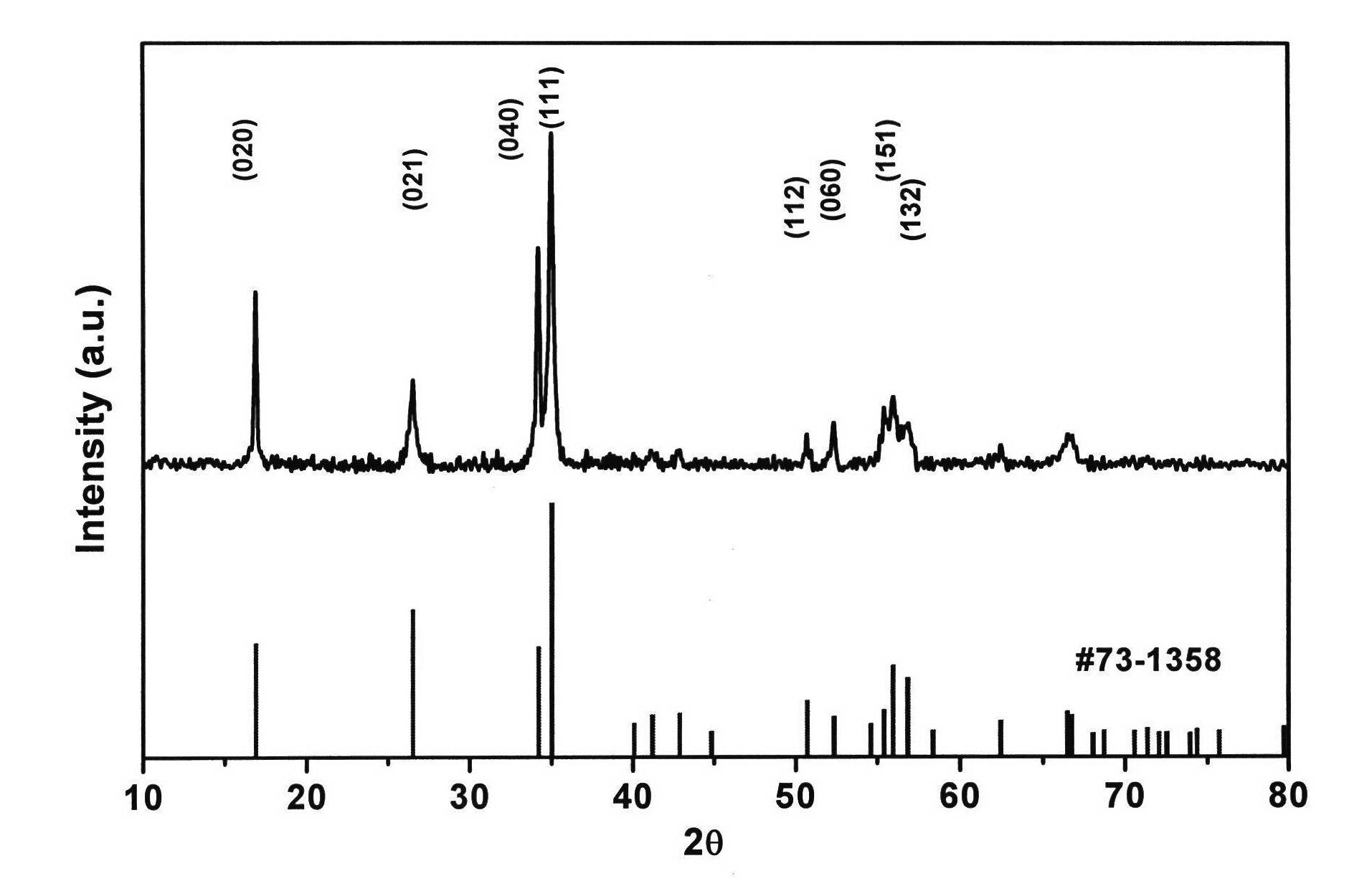

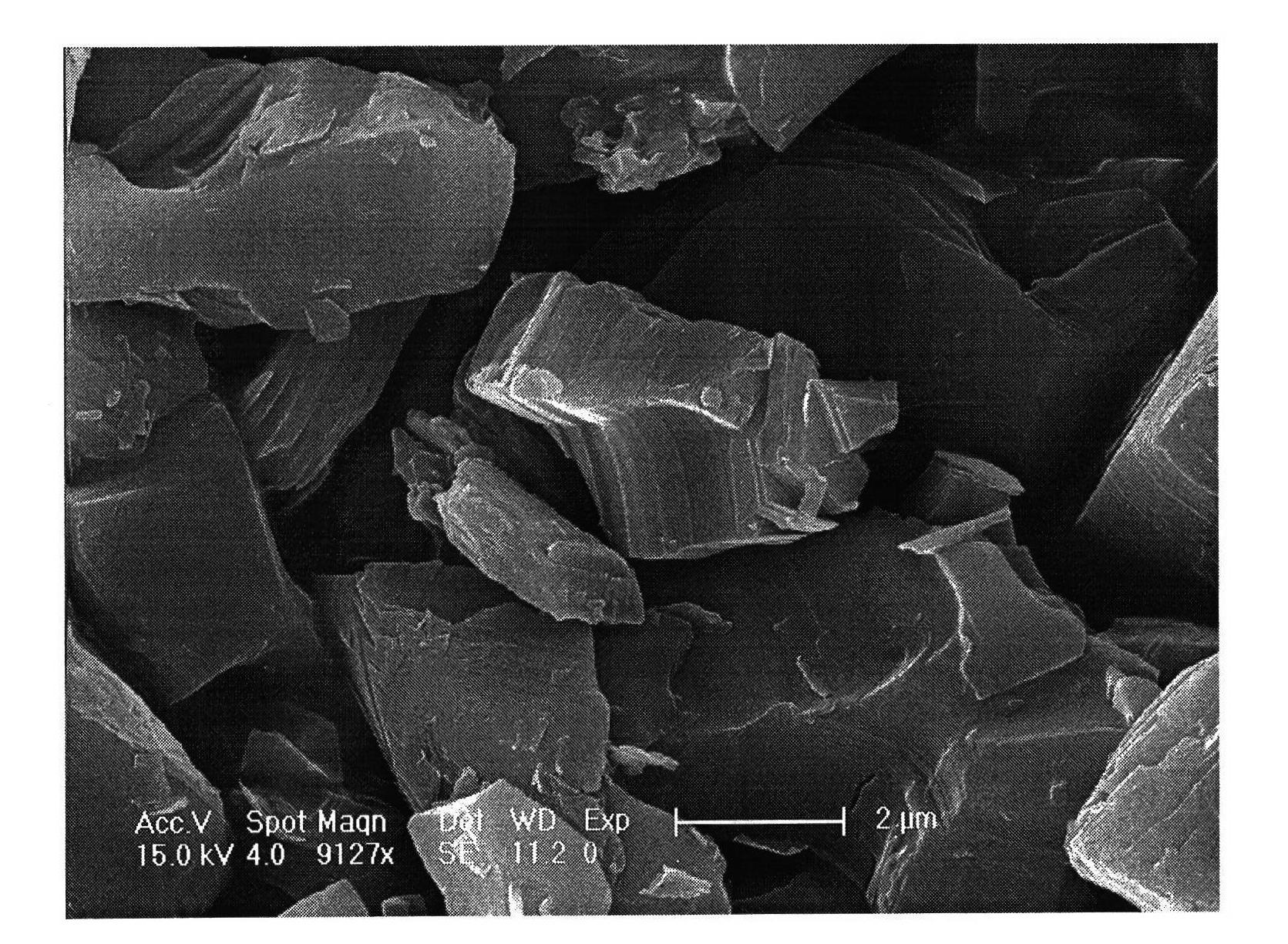

[0016] Encapsulate white phosphorus in a high-voltage casing with an appropriate volume, cover the top and bottom with heat-conducting and pressure-transmitting medium gaskets, encapsulate it with a high-pressure reaction module, and place it on a six-sided high-pressure press with a given pressure of 2GPa and a given temperature of 300°C , after 60 minutes pressure relief annealing. Gained black phosphorus sample is ground into powder, with polytetrafluoroethylene as binder, N-methylpyrrolidone as organic solvent, acetylene black as conductive agent, according to black phosphorus: acetylene black: polytetrafluoroethylene=80% : 10%: 10% ratio of mixing and stirring evenly, the slurry was coated on the copper foil current collector, and vacuum-dried at 120° C. for 10 hours.

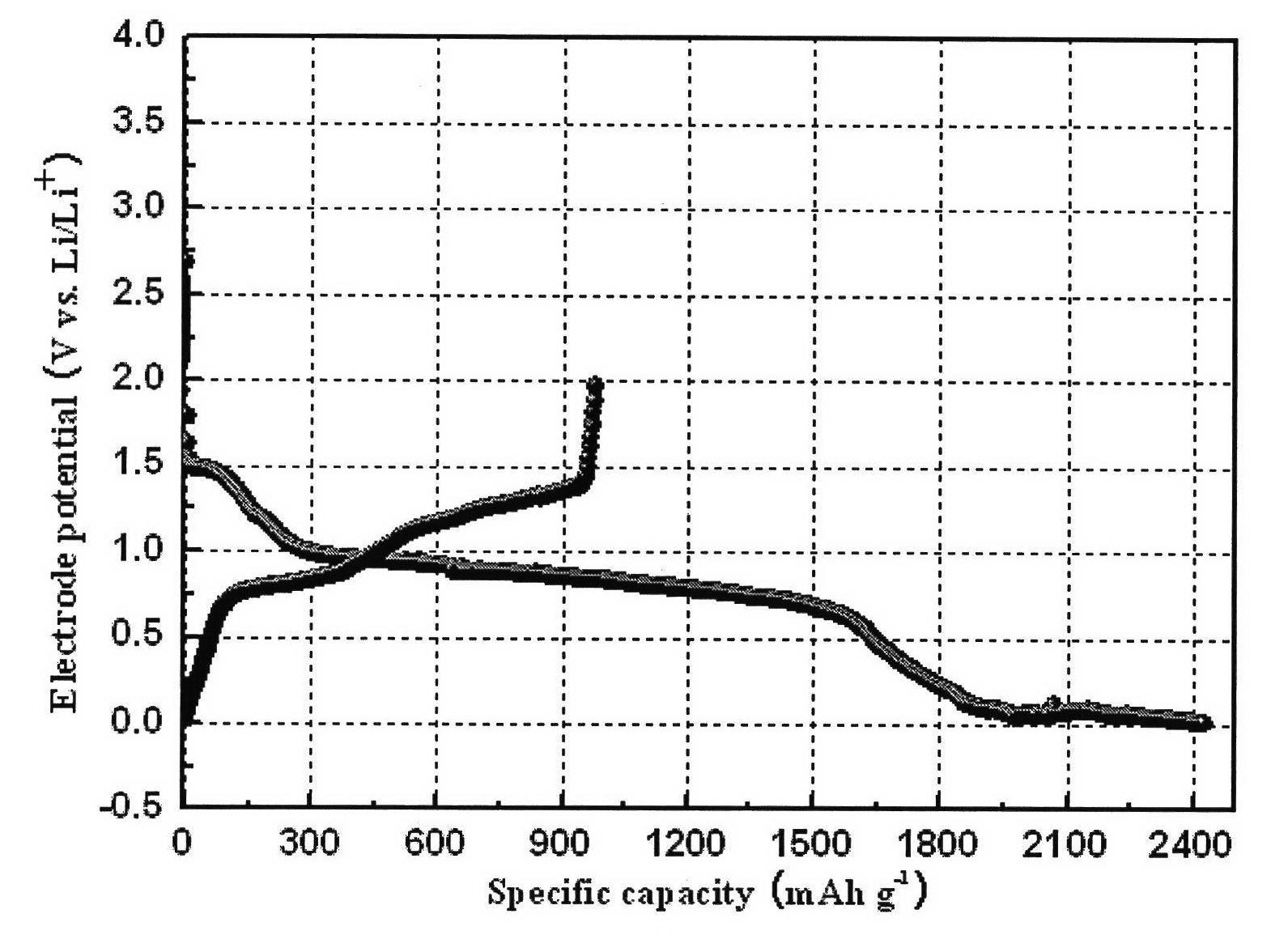

[0017] With lithium sheet as the counter electrode, 1mol / L LiPF is used 6 The mixed solution in ethylene carbonate and diethyl carbonate with a volume ratio of 1:1 is the electrolyte. The diaphragm is Ce...

Embodiment 2

[0019] Encapsulate white phosphorus in a high-voltage casing with an appropriate volume, cover the top and bottom with heat-conducting and pressure-transmitting medium gaskets, encapsulate it with a high-pressure reaction module, and place it on a six-sided high-pressure press with a given pressure of 4GPa and a given temperature of 400°C , after 30 minutes pressure relief annealing. Gained black phosphorus sample is ground into powder, with polytetrafluoroethylene as binder, N-methylpyrrolidone as organic solvent, acetylene black as conductive agent, according to black phosphorus: acetylene black: polytetrafluoroethylene=80% : 10%: 10% ratio of mixing and stirring evenly, the slurry was coated on the copper foil current collector, and vacuum-dried at 120° C. for 10 hours.

[0020] With lithium sheet as the counter electrode, 1mol / L LiPF is used 6 The mixed solution in ethylene carbonate and diethyl carbonate with a volume ratio of 1:1 is the electrolyte. The diaphragm is a ...

Embodiment 3

[0022] The red phosphorus is compacted, packaged in a high-voltage casing, covered with heat-conducting and pressure-transmitting medium gaskets, packaged in a high-pressure reaction module, and placed on a six-sided top high-pressure press with a given pressure of 4.5GPa and a given temperature 800°C, after 20 minutes, pressure relief annealing. The obtained black phosphorus sample is ground into a powder, with polytetrafluoroethylene as a binder, N-methylpyrrolidone as a dispersant, and acetylene black as a conductive agent, according to black phosphorus: acetylene black: polytetrafluoroethylene=80% : 5%: 15% by mixing and stirring evenly, coating the slurry on the copper foil current collector, and vacuum drying at 120° C. for 6 hours.

[0023] With lithium sheet as the counter electrode, 1mol / L LiPF 6 The mixed solution of ethylene carbonate, diethyl carbonate and dimethyl carbonate at a volume ratio of 1:1:1 is the electrolyte. The diaphragm is Celgard2400 microporous m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com