Chemical grating preparation method of partial fluorine-containing polymer based anion-exchange membrane

An anion exchange membrane and chemical grafting technology, which is applied in the field of chemical grafting preparation of some fluoropolymer-based anion exchange membranes, can solve the problems of difficult mass production, unstable functional groups, and high equipment requirements, and achieve easy Realize the effects of large-scale industrial production, convenient source of raw materials and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

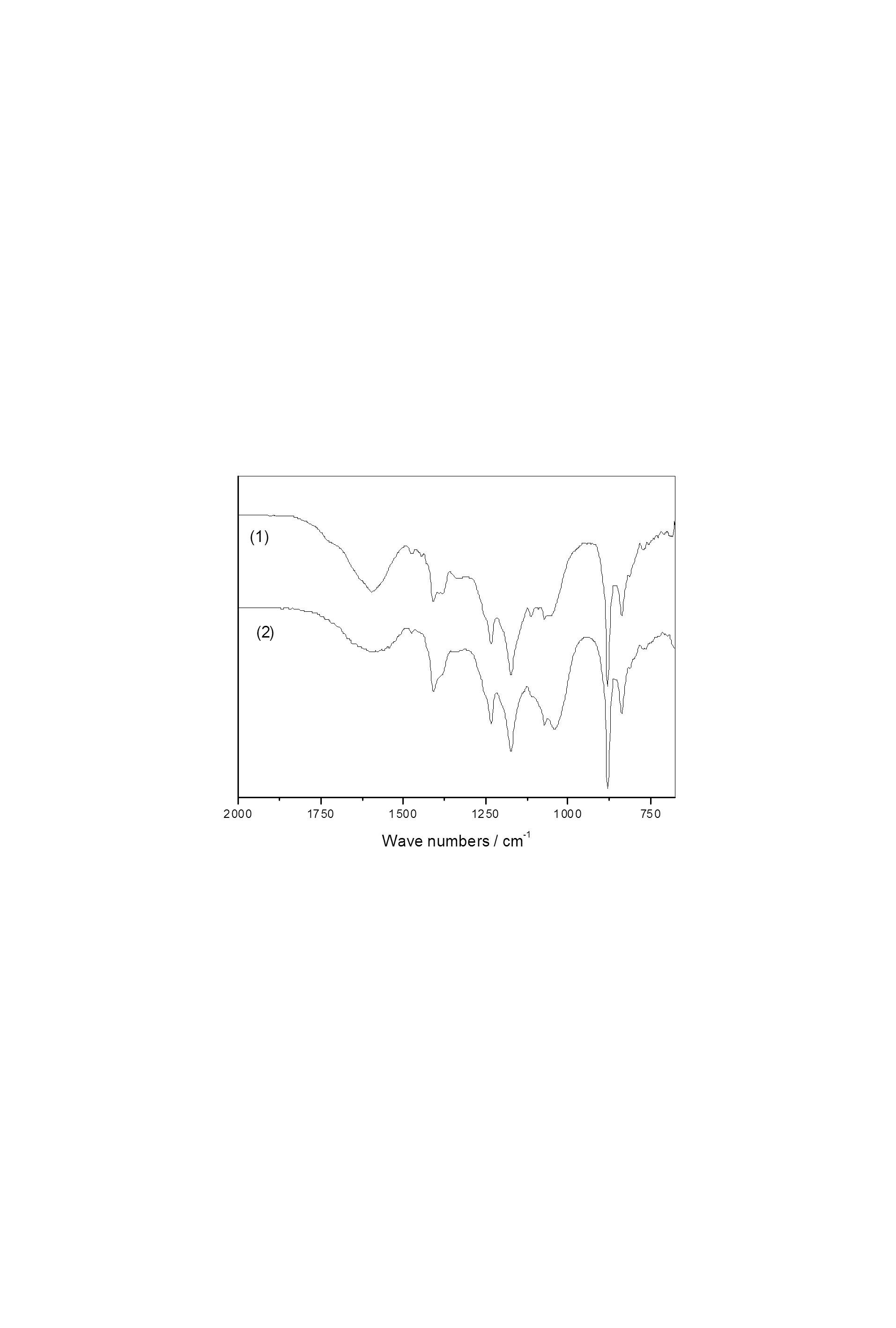

Image

Examples

Embodiment 1

[0042] Dissolve polyvinylidene fluoride powder in N,N-dimethylformamide solvent, stir to dissolve it, and prepare a solution with a mass percentage of 10% fluoropolymer to obtain a liquid film with a thickness of 1000μm. Completely degas and scrape the film; then dry at 40°C for 24 hours to obtain part of the fluoropolymer base film. Add 2mol / L NaOH ethanol solution to the three-necked flask, and add 3mg / ml n-tetrabutylammonium bromide (TBAB) phase transfer catalyst aqueous solution, added n-tetrabutylammonium bromide phase transfer catalyst aqueous solution and NaOH ethanol solution The volume ratio is 1:20. Under the protection of nitrogen, the part of the fluoropolymer base film is immersed in the mixed solution, and the alkali treatment is carried out at 50°C for 30 minutes to obtain the alkali treatment film; put the tetrahydrofuran solvent in a three-necked flask and add Initiator dibenzoyl peroxide, the initiator concentration is 1.7×10 -2 mg / ml, under the protection of ...

Embodiment 2

[0044] Dissolve polyvinylidene fluoride powder in N,N-dimethylformamide solvent, stir to dissolve it, prepare a solution with a mass percentage of fluoropolymer of 12%, and let it stand until it is completely degassed and scrape the film to obtain A liquid film with a thickness of 800μm; then dried at 100°C for 5h to obtain a part of the fluoropolymer base film. Add 5mol / L NaOH ethanol solution to the three-necked flask, and add 3mg / ml n-tetrabutylammonium bromide (TBAB) phase transfer catalyst aqueous solution, added n-tetrabutylammonium bromide phase transfer catalyst aqueous solution and NaOH ethanol solution The volume ratio is 1:20. Under the protection of nitrogen, this part of the fluoropolymer base film is immersed in the mixed solution, and the alkali treatment is carried out at 70°C for 5 minutes to obtain the alkali treatment film; put the tetrahydrofuran solvent in a three-necked flask and add Initiator dibenzoyl peroxide, make the initiator concentration 1mg / ml, un...

Embodiment 3

[0046] Dissolve the polyvinylidene fluoride powder in N,N-dimethylformamide solvent, stir to dissolve it, prepare a solution with a mass percentage of fluoropolymer of 11%, let it stand until it is completely degassed, and scrape the film to obtain A liquid film with a thickness of 600μm; then dried at 70°C for 9h to obtain a part of the fluoropolymer base film. Add 4mol / L NaOH ethanol solution into the three-necked flask, and add 3mg / ml n-tetrabutylammonium bromide (TBAB) phase transfer catalyst aqueous solution, added n-tetrabutylammonium bromide phase transfer catalyst aqueous solution and NaOH ethanol solution The volume ratio is 1:20. Under the protection of nitrogen, the part of the fluoropolymer base film is soaked in the mixed solution, and the alkali treatment is performed at 60°C for 20 minutes to obtain the alkali treatment film; take the tetrahydrofuran solvent into a three-necked flask and add Initiator dibenzoyl peroxide, make the initiator concentration 0.5mg / ml,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com