Preparation method of meta-material dielectric substrate

A dielectric substrate and metamaterial technology, applied in the field of metamaterials, can solve the problem that the dielectric substrate does not have the electromagnetic modulation function, and achieve the effect of enriching the electromagnetic modulation function and expanding the application of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a metamaterial dielectric substrate, the dielectric substrate adopts a porous ceramic substrate, comprising the following steps:

[0028] a. Prepare polyvinylidene fluoride, polystyrene and polyethersulfone as the organic solution of the solute, and the solvent all adopts chloroform;

[0029] b. First, the polyvinylidene fluoride solution is added to the disc-shaped porous ceramic substrate, and it can be dripped from the center of the disc-shaped porous ceramic substrate when dripping;

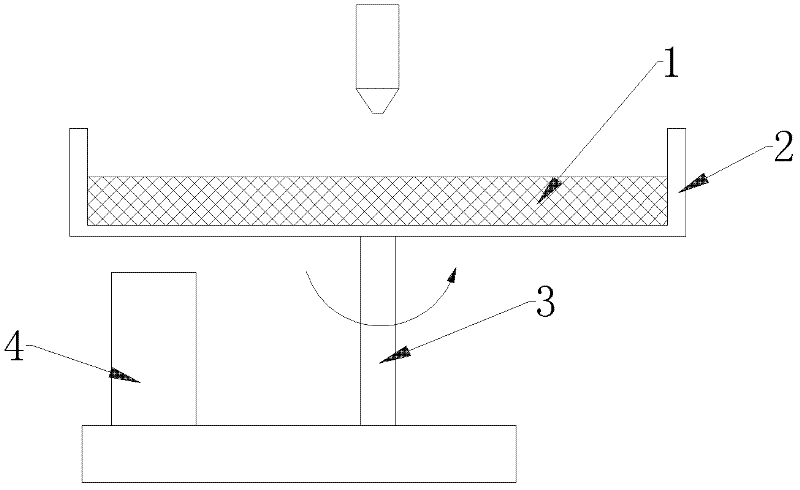

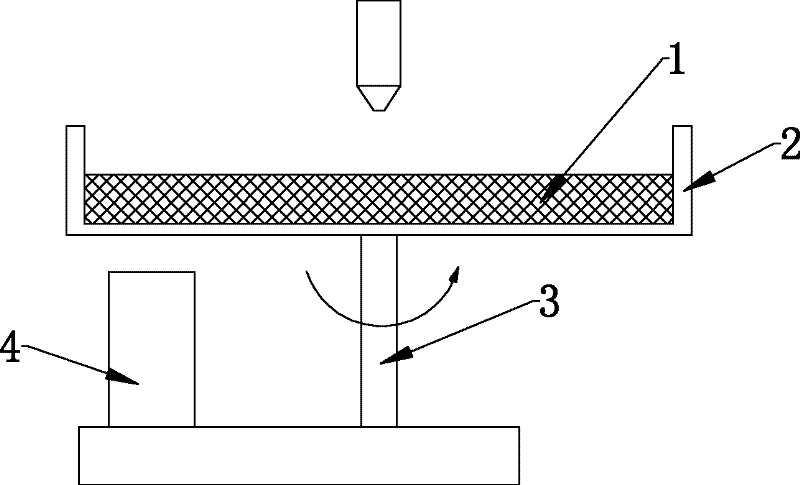

[0030] c. The porous material substrate is subjected to centrifugal rotation, and the schematic diagram of the centrifugal rotation operation can be found in the attached figure 1 , the disc-shaped porous ceramic substrate 1 is placed inside a cylindrical mold 2, a rotating shaft 3 is arranged below the mold 2, and the mold 2 can be centrifugally rotated through the rotating shaft 3, and the disc-shaped porous ceramic substrate 1 After the polyvinylidene fluorid...

Embodiment 2

[0036] A method for preparing a metamaterial dielectric substrate, the dielectric substrate adopts a porous ceramic substrate, comprising the following steps:

[0037] a. preparation mass fraction is 0.2% polystyrene solution, solvent adopts chloroform;

[0038] b. Add barium titanate powder with a high dielectric constant as a dielectric material into the polystyrene solution, mix it evenly, and then add it to the porous ceramic substrate;

[0039] c. The porous material substrate is subjected to centrifugal rotation, and the schematic diagram of the centrifugal rotation operation can be found in the attached figure 1 , the disc-shaped porous ceramic substrate 1 is placed inside a cylindrical mold 2, a rotating shaft 3 is arranged below the mold 2, and the mold 2 can be centrifugally rotated through the rotating shaft 3, and the disc-shaped porous ceramic substrate 1 After the polystyrene solution is added above, the polystyrene solution is distributed to the edge area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com