High-strength cold-rolled steel sheet and method for producing same

A cold-rolled steel sheet and a manufacturing method technology, which are applied in the field of high-strength cold-rolled steel sheet and its manufacturing, can solve the problems of small surface deformation suppression effect, easy generation of surface deformation and punching cracks, and difficulty in reducing surface deformation, and achieve chemical conversion treatment. Excellent properties and corrosion resistance, small material change, low YP effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

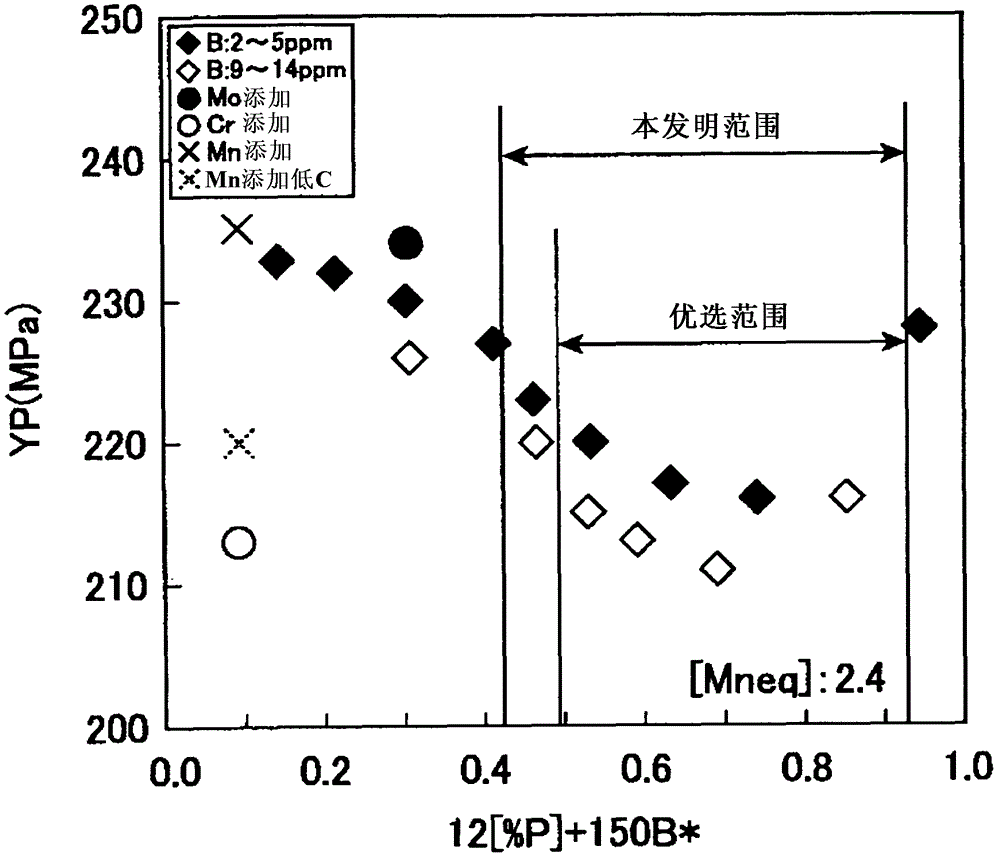

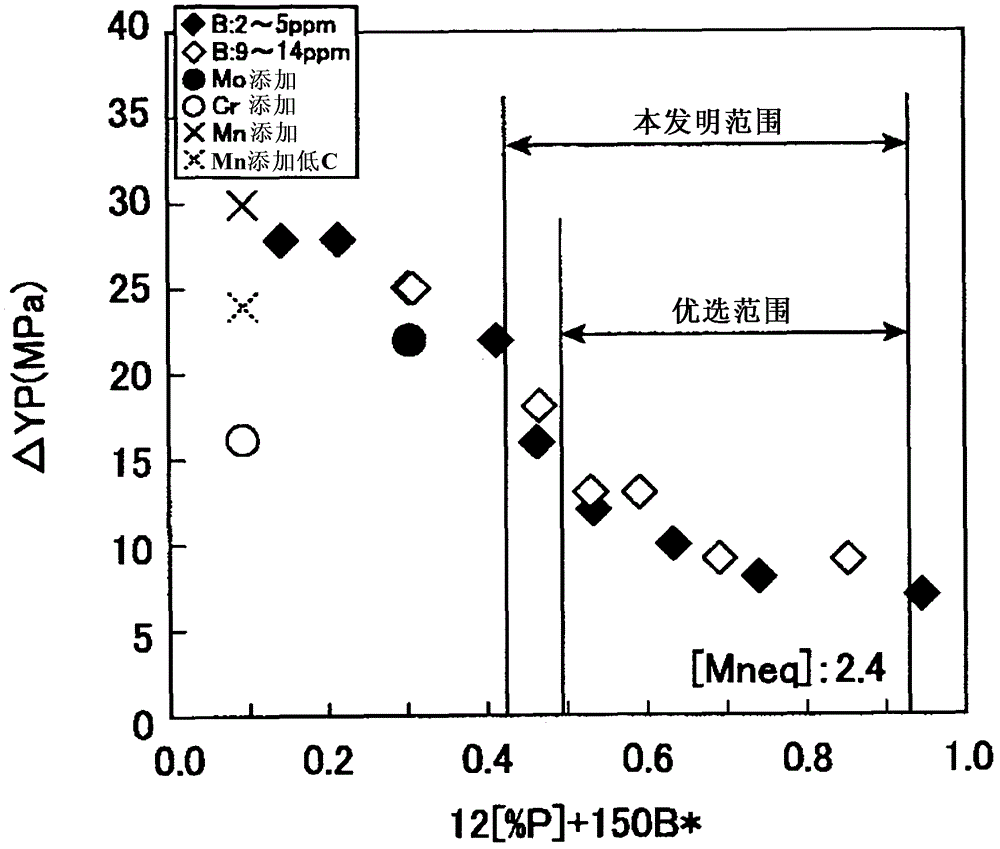

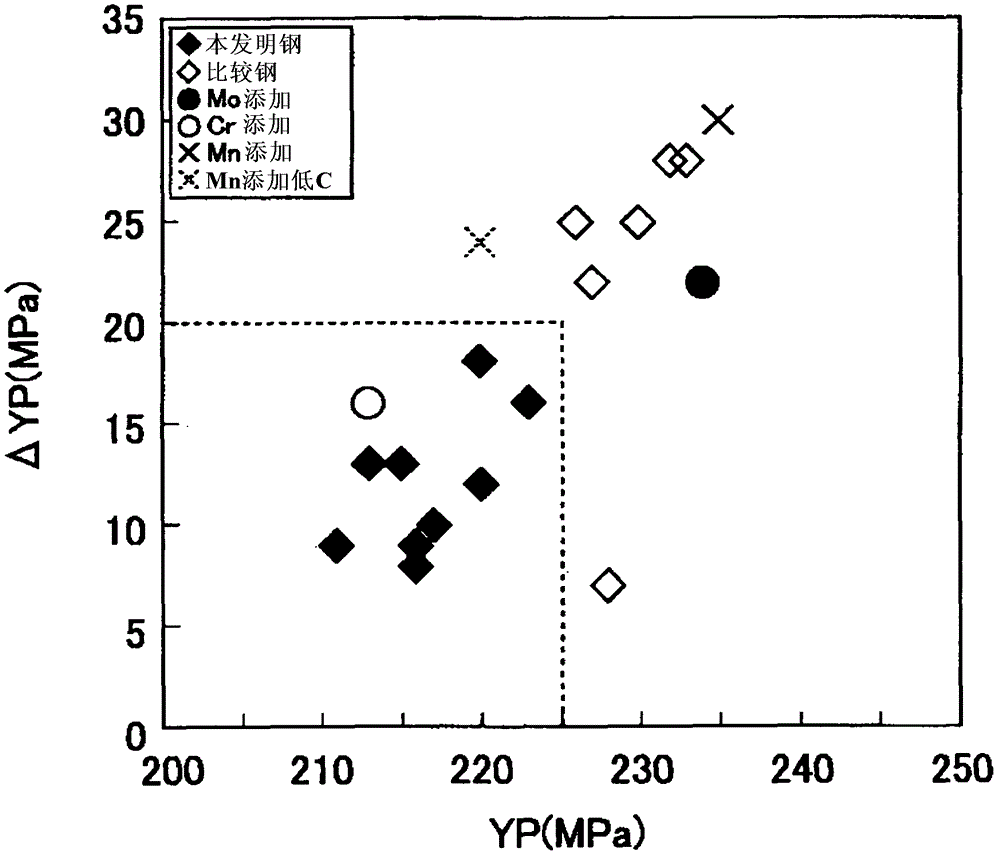

[0215] After melting the steels with the compositions shown in Tables 1 and 2, they were continuously cast into slabs with a thickness of 230 mm, heated to 1180 to 1250°C, and then hot rolled at a finishing temperature in the range of 820 to 900°C. Then, it is cooled to 640° C. or less at an average cooling rate of 20 to 40° C. / sec, and coiled at a coiling temperature CT of 400 to 630° C. The obtained hot-rolled sheet was cold-rolled at a rolling ratio of 68 to 78% to obtain a cold-rolled sheet having a thickness of 0.8 mm.

[0216] In CAL, the obtained cold-rolled sheet was heated at a heating temperature of 680 to 750° C. at an average heating rate of 0.9 to 15° C. / sec, and annealed at an annealing temperature AT for 40 seconds. The annealing temperature AT shown starts the primary cooling up to 480°C, then performs the secondary cooling from 480°C to Tc represented by the above formula (6), and further performs the three-time cooling from the above Tc to 200°C After coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com