Pneumatic tire for vehicle

A technology for pneumatic tires and vehicles, applied to vehicle parts, tire parts, tire treads/tread patterns, etc., can solve problems such as detrimental handling characteristics, detrimental dry braking characteristics, and reduced circumferential rigidity to achieve good performance Wetting and slippery properties, good dry handling properties, frizz-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

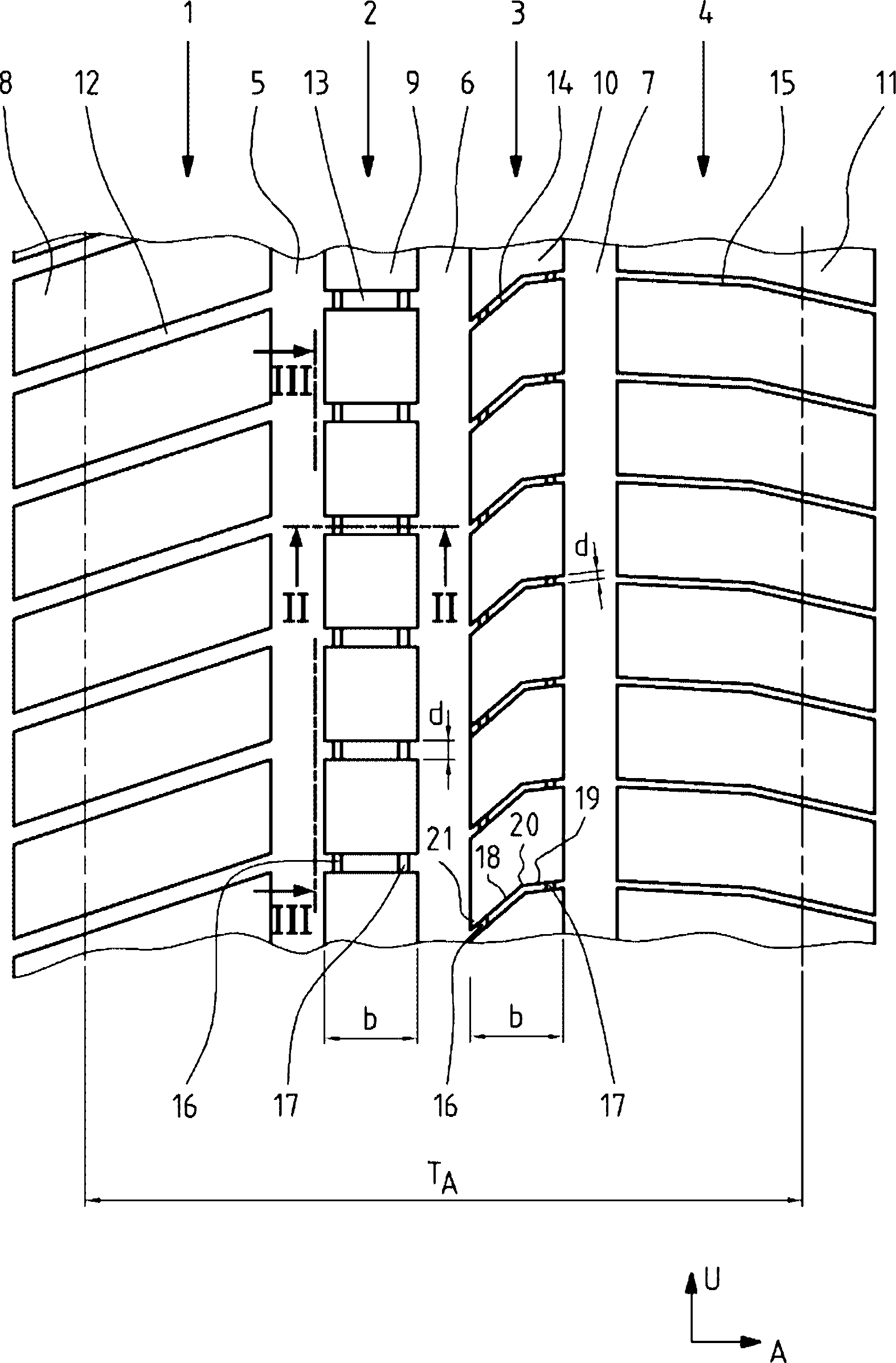

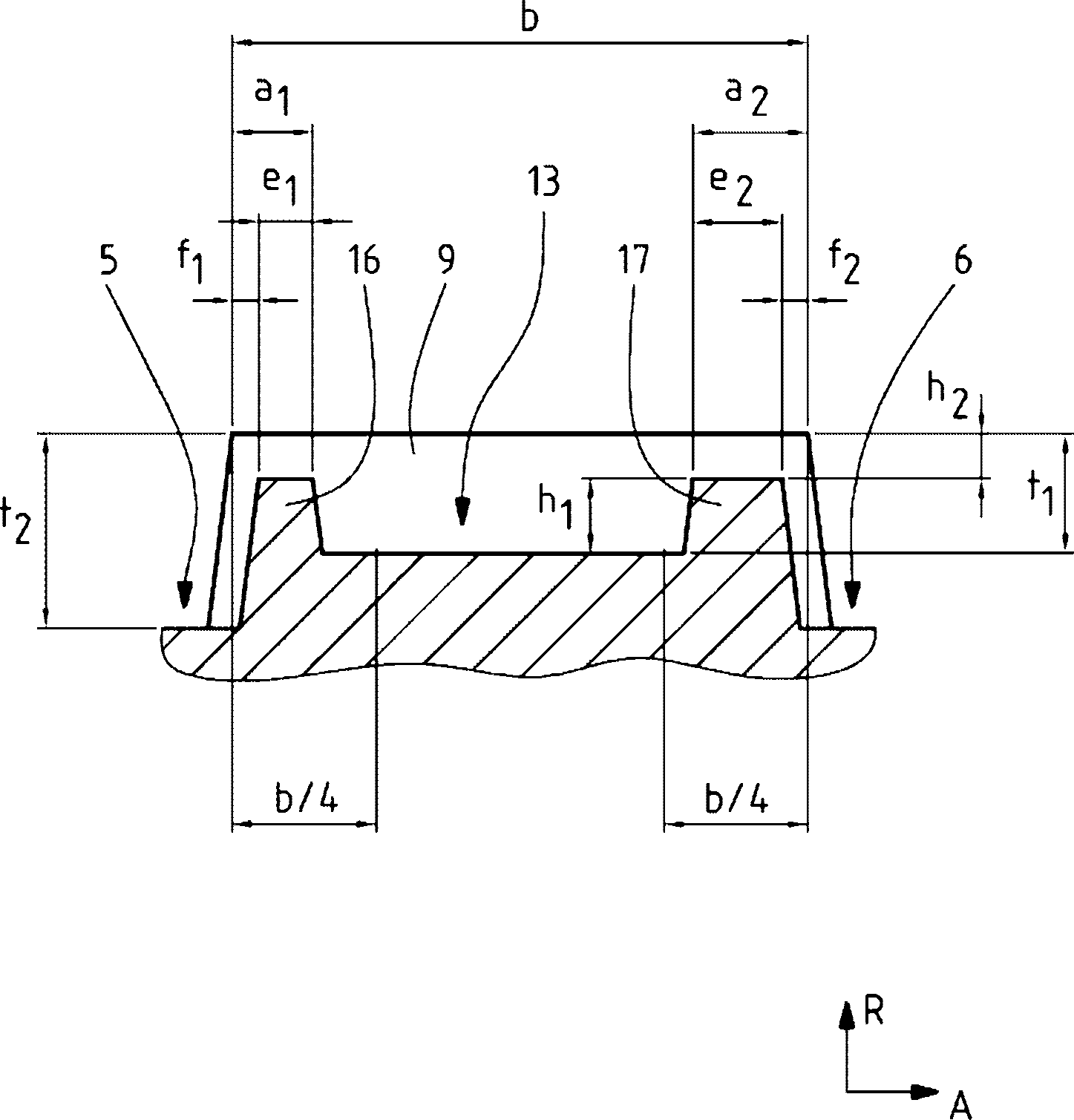

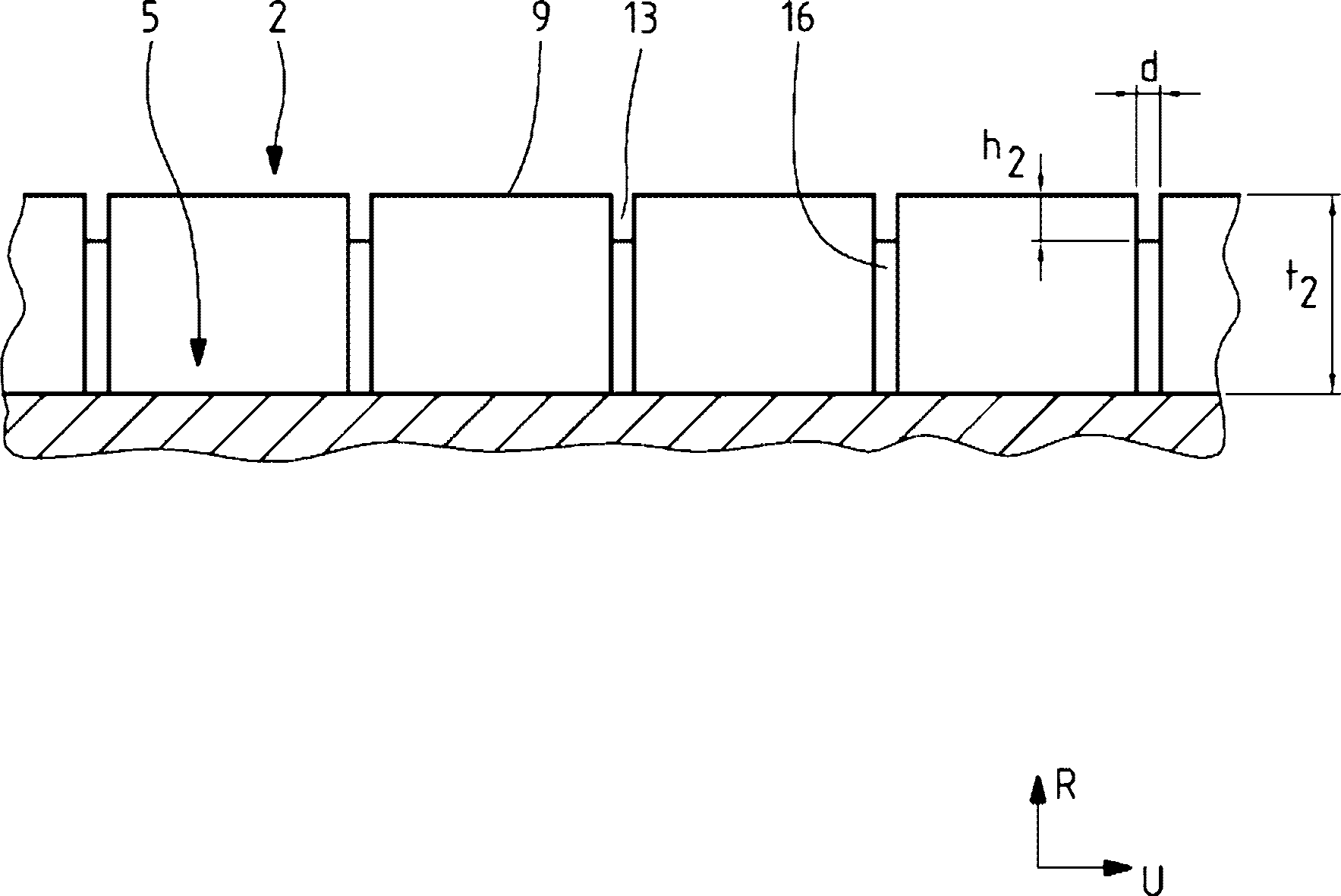

[0043] Figure 1 to Figure 3 The tread stripes of a vehicle pneumatic tire for a passenger car in radial configuration are shown. The tread stripes are summer treads.

[0044] exist figure 1 Shown from left to right in , the tread stripes are composed of shaped block rows 1, 2, 3 and 4 arranged successively in the axial direction A. Forming block rows 1 and 4 are shoulder forming block rows. The shaped block rows 1 to 4 respectively extend along the circumferential direction U of the vehicle pneumatic tire over the entire circumference of the vehicle pneumatic tire. The profiled block rows 1 and 2 are formed such that they are spaced apart from each other in the axial direction A by a prior art circumferential groove 5 , which is oriented in the circumferential direction U and extends over the entire circumference. The profiled block row 2 and the profiled block row 3 are formed such that they are spaced from each other in the axial direction A by a prior art circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com