Method for separating acetic acid from water by rectification of acetic acid dehydrating tower

A technology for acetic acid dehydration and rectification separation, which is applied in the separation/purification, fractionation, organic chemistry and other directions of carboxylic acid compounds, and can solve the problems of high operating costs, high energy consumption for acetic acid dehydration, and high equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

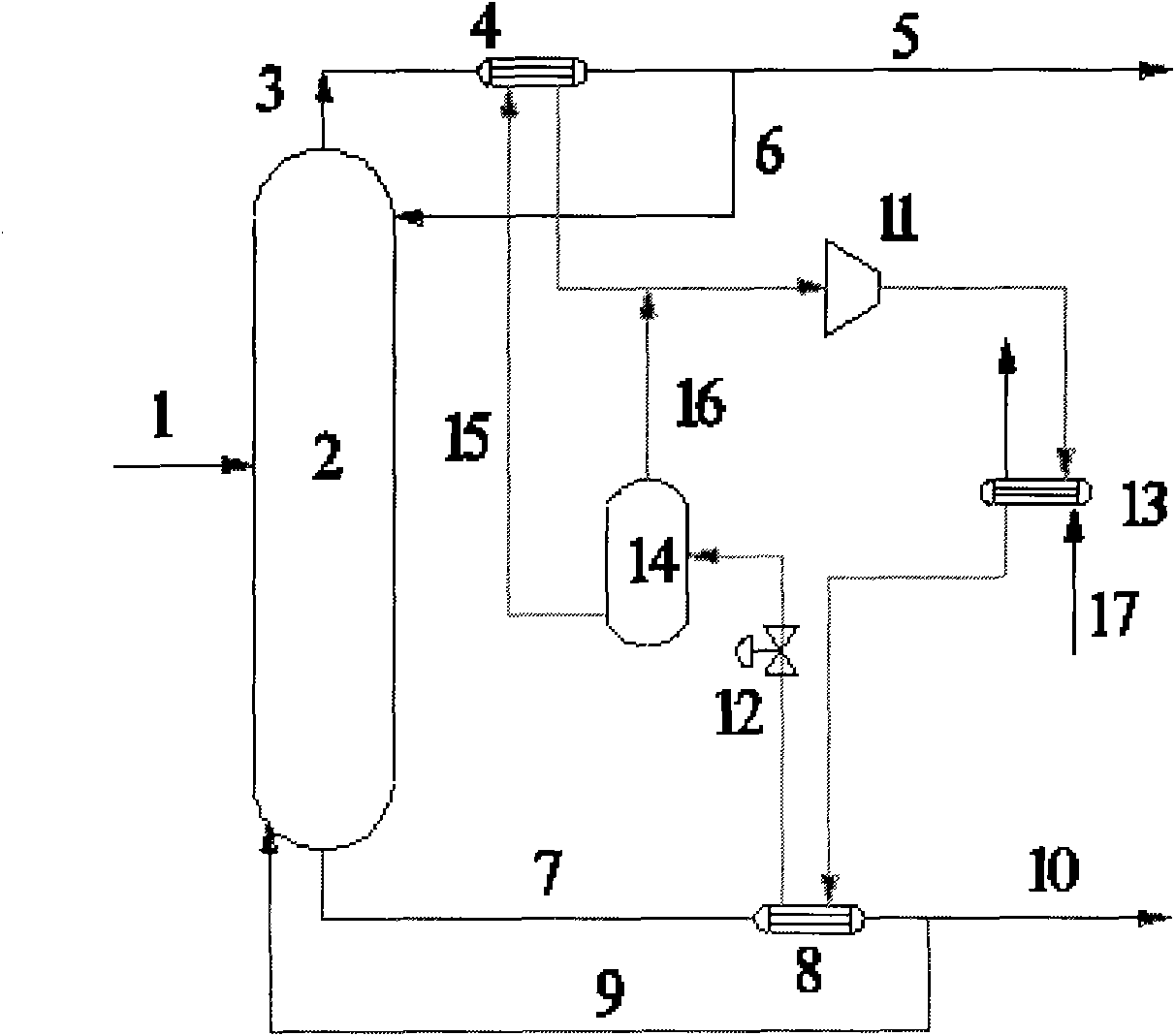

[0032] use figure 1 Shown flow process, dilute acetic acid aqueous solution adopts the mode of azeotropic rectification to carry out dehydration, and acetic acid aqueous solution 1 (wherein acetic acid concentration is 38 mass %) enters acetic acid dehydration tower 2 from the middle, after rectification separation, tower top obtains gaseous phase stream 3, The tower kettle obtains the liquid phase stream 7; the stream 3 is divided into the stream 5 and the stream 6 after the heat exchange and condensation of the condenser 4, and the stream 5 enters the follow-up process as the tower top product discharge, and the stream 6 returns to the top of the acetic acid dehydration tower 2; the stream 7 After heat exchange by the reboiler 8, it is divided into a stream 9 and a stream 10, the stream 9 returns to the bottom of the 2, and the stream 10 enters the subsequent process as a product discharged from the tower kettle. The concentration of acetic acid in the discharge from the bot...

Embodiment 2

[0043] Same as [Example 1], except that the heat exchange medium water is changed to cyclohexane, and the pressure of cyclohexane on the shell side of the tower top condenser is normal pressure, and the remaining operating pressures remain unchanged.

[0044] After the gas-liquid separation tank is added in the method of the invention, the operating state of the condenser is more stable. When there is a gas phase in the stream, the entry of the gas phase will cause the vibration of the condenser and damage the equipment; when the gas phase is separated, the entry of the pure liquid stream can stabilize the operation of the condenser, thereby improving the service life of the device and reducing operation. cost.

[0045] The energy consumption is shown in Table 1, and the heat transfer efficiency and equipment cost are shown in Table 2.

[0046] As can be seen from Table 1, compared with pressurized rectification, every ton of concentrated acetic acid-water solution produced, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com